Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Discoloration of Black Anodized Aluminum Parts

Q. I'm a Mechanical Engineer in charge of an optical sub-assembly that is assembled to a diagnostic blood analyzer. The problem is that a black anodized housing has changed in color from Black to a Pink-Platinum appearance.

Does anyone know what is causing this color change?

B. Kling-Pittsburgh, Pennsylvania

1998

----

Ed. note: Fading of black anodized parts is a very common problem, addressed many times on this site, so readers may also be interested in

- letter 15825, "Black anodize turning bronze color",

- letter 22602, "Black Anodized parts fading to brown / bronze",

- and letter 31658, "Black anodized parts fading - Non-UV cause".

|

|

A. The choice of dye, the quality of the seal, the quality of the anodizer and lots of UV light from the fluorescent lights. James Watts- Navarre, Florida 1998 A. Some possible reasons / explanations for the discoloration: 1) All dyes have different lightfastness & heat-fastness ratings meaning how well they hold up to light & heat. There are many Black dyes available on the market today - some cheap & some very expensive. The cheaper ones can discolor. 2) The anodize may not be properly sealed & the dye may have leached out. David A. Kraft- Long Island City, New York 1998 A. Depending upon the color anodize process used to produce your parts there may a number of causes. If these parts are being produced by organic dye impregnation processes, than I would first look at the method and efficacy of the sealing process, as you probably have the dye compound being attacked by some agent. Sealing processes are the primary influence that determines the color fastness of the dyed part. Some dyes have better light fastness than others, and that is a factor also. I would start evaluating the seal quality of the parts with a dye stain test, or light fastness testing at the process house. One of the two agents in my opinion which would most likely affect the black color turning pink as you have described, would be application of cleaning agents or disinfectants such as dilute clorox solutions, etc., which have non-neutral pH properties and/or are oxidizing compounds. The other agent might be ultraviolet light such as experienced in high output fluorescent light applications as hospitals, labs, etc. have. Are these parts new from the vendor? What do they come into contact with? How are they being sealed? Again, I would put into your acceptance criteria for the parts in question a seal test. Ward Barcafer, CEFaerospace - Wichita, Kansas 1998 A. This sounds like a classic case of fading color due to light exposure. In case you don't know exactly what a black anodize coating is, aluminum is electrolytically (anodically) oxidized to form a porous aluminum oxide coating. The porous oxide will absorb water soluble colored dyes of just about any color, then the pores are sealed to prevent absorption of any unwanted contaminants. Most of the dyes, including black, are complex organic compounds which are unfortunately highly susceptible to oxidation and degradation by UV light. The sealing process helps to slow down the UV degradation, but cannot totally stop it. That is why you will see very little organically dyed anodized aluminum outdoors- the dye manufacturers have not come up with UV-resistant organic dyes. Without knowing anything about blood analyzers, I would bet that the optical system includes some sort of UV analyzer system. The black dye in your housing's anodize has been destroyed. If this is the problem, you have two choices: 1) Switch to black paint. The pigment in black paint is carbon black, which is, of course not susceptible to UV degradation. The paint's binder could be susceptible, however, so the paint would have to be one known to be UV resistant. 2) If anodize is the preferred coating, have your housings anodized and electrolytically colored black. The anodized parts are colored in this case by a second electrolytic bath which deposits metallic tin or nickel in the pores of the anodize prior to sealing. A range of colors is obtained, including black, through a light-scattering phenomenon. Since there are no organics involved, the color is not subject to UV degradation. Not all anodizers are equipped to do electrolytic coloring, so if your current anodizer is not equipped, you may find one in your area by checking the member directory of the Aluminum Anodizers Council at www.aac.org.

|

A. All of the answers you have obtained thus far have merit. However, I believe one or two important factors have been missed.

In order to obtain a good, lightfast black color, it is imperative to anodize to at least 0.6 - 0.7 mil oxide thickness. This gives you enough "pore capacity" to hold sufficient organic dye to minimize the UV effects on the dye.

It is also very important to dye the parts to "full adsorbancy", that is ... allow the part to remain in the dye solution until the pores will not adsorb any more dyestuff. For good black color, this can be as long as 30 minutes, but usually 20 minutes is sufficient.

After this has been done, a good nickel containing seal is imperative to minimize leaching of the dye and to adequately seal the part.

If you have any additional questions please let me know.

Charlie Grubbs- Alpharetta, Georgia

1998

Q. Can anyone help me, I have a dark grey anodized aluminium part, the finish looks like water color, it looks like the dye has run, some areas are darker than other. The plater claims this is due to a material change, is this true?

Also when a thin plate is rubbed against the finish, it appears to scrape the surface right back to the aluminium. Is this linked? Thanks

student - Ireland

2007

Aluminum How-To

"Chromating - Anodizing - Hardcoating"

by Robert Probert

Also available in Spanish

You'll love this book. Finishing.com has sold almost a thousand copies without a single return request :-)

A. Hi, Ciaran.

It sounds like the anodizing is too thin in spots if not everywhere. The dye only works when absorbed into the pores of the anodized film; if it is too thin you will not get saturated colors.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. It sounds like there is a standardized rating index for color fastness. We have a similar problem where black-anodized parts turn pink after a few weeks where there is intense fluorescent lighting. Is there a standard color fastness rating system? Is there a recommended rating for continuous outdoor use? What kind of testing is done to establish the colorfastness rating of a dye?

Bill Lanier- Billeriac, Massachusetts

July 8, 2008

A. The dye manufacturers have a rating system for dye stability. Find out which one your anodizer is using and check to see for yourself on what its relative rating is.

Black organic dyes do not like fluorescent lights at all.

There are some metal based ones that will last longer. Finally, you can use the two step system for architectural anodizing that can obtain some dark colors, but tend to have lighter tones. Black is not really possible, but some anodizers can come close.

- Navarre, Florida

July 11, 2008

Q. Hey B. Kling, did you ever discover what was causing your anodized parts to discolor? I am a Mechanical Engineer and have encountered the same problem: black anodized parts (type 2, class 2 - sulfuric acid anodized, dyed) turning to a pinkish-purple color.

The particular parts we are seeing discolor are on process pumps, but we have many parts from other products anodized by the same supplier and we have never seen this problem. The parts are not exposed to much UV light so I'm a little lost as to why these parts are discoloring.

- Minneapolis, Minnesota

July 12, 2011

July 12, 2011

Treatment &

Finishing of

Aluminium and

Its Alloys"

by Wernick, Pinner

& Sheasby

(note: this book is two volumes)

on eBay or

AbeBooks

or Amazon

(affil links)

A. Hi, M.

My first guess is that the parts in question are a different alloy or use a different fabrication method which causes the anodizing to be thinner. Please look over Charlie Grubbs response about the need for thick anodized coatings for good, stable, saturated blacks. Find out from your vendor, or through your own testing, how thick the anodized coating is on the parts that fade. Certain alloys, like 2xxx series, require significantly higher voltage and processing time to acquire the same thicknesses as 6xxx alloys.

It's usually best to address all readers because these threads stay on line as reference information for years; I don't know B. Kling, but he could have retired a decade ago :-)

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 21, 2011

Q. Hi,

I am involved in the design of UV lamps, principally for the printing industry.

Some of the external covers we use are made from Aluminium Alloy which are anodised black.

These covers very often become 'bleached' due to the presence of UV light.

We have had an enquiry from one customer who operates one of our lamps in a 'Clean Room'

environment and wants to know whether the bleaching process causes any minute particle to

be released into the atmosphere. Any ideas?

Product Designer - United Kingdom

A. Hi Alan. I can't say for absolutely positively, but I strongly doubt it because the dye is sealed into the anodizing pores, that is, the top of the pores are sealed off.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

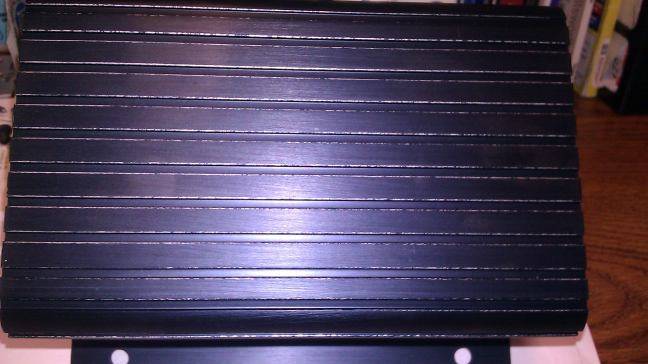

Q. I am having black anodizing problems. I have a Cover, made out of an extrusion, that has groove lines around the cover. In the flat area I paint black. But in the edges of each groove and edges of the cover I have a lot of white.

Now the supplier claims that with another supplier it plates Okay.

When you etch it comes dark gray. What could it be?

Thanks.

Charles

- Carolina, Puerto Rico

June 28, 2012

A. Hi Charles. Photos can sometimes not convey things correctly, but it looks to me like your cover is purple rather than black, indicating lack of saturation due to the anodizing being too thin. As long as the anodizing is still too thin, it may not be sufficiently insulative to divert the current and steer it to the low current density areas (which is the bottom of the grooves, which you have painted, if I understood correctly).

But I don't think that's really the problem with the edges. Perhaps they are not truly clean, or perhaps the current density was too high and these edges burned.

Grayness when etching is to be expected. Aluminum alloys contain other materials like copper and silicon which are left behind when you etch away the aluminum. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

October 4, 2012

Q. We manufacture black anodized aluminium alloy diecastings, the products are used outside and always exposed to sunlight. We are looking for ways to improve the UV resistance currently we use and MLW type of anodizing but the color still changes a lot.

The anodizing process line is very stable all automated so we expect to make the best improvement switching the coloring;

can anybody recommend a very good UV stable type of coloring ink which is worldwide available?

- Ningbo, China

August 15, 2013

A. The MLW that I am familiar with is a good black dye. It is possible that you are using a knock-off product.

All black dye will fade/turn purple in strong UV conditions.

The best that you can do is to have the anodize a bit thicker and use a very good seal after the dye.

You also mention switching to an ink. I am not familiar with this type of product.

For superior UV resistance, you would have to switch to architectural anodizing which involves plating with one of two metal salts after anodizing. Unfortunately, true black is not an option in this process and it obviously costs more.

- Navarre, Florida

August 16, 2013

A. Hi. Another, but costly, solution would be an add-on to James' reply: overdyeing, which means the electrolytic coloring with the metal salt that he speaks of, followed by conventional organic dyeing.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

August 19, 2013

Q. We are an OEM manufacturer. We make parts that get sent out for anodizing which we then assemble into the finished good. Starting about five years or so ago, we noticed that some of our black parts have been exhibiting fading to some degree. One customer has experienced our black parts fading to silver in under three months. We have tried specifying the dye (Sanodal Deep Black HBL), the type of seal (nickel acetate) and even the plating shop (we have several we use). These are small parts (about 5/8" diameter by about 1" long for one and 1/2" diameter by about 1/2" long for the other). They are made from 2024-T3 or higher. We are now on our third plating shop, all have told us their parts will not fade, but they all have. Even the "architectural" platers samples faded.

If I were to start over with this part, same geometry but new material and possibly new plating process, what would your plating experts recommend I do to get a standard MIL-A-8625, Type II, Class 2, Dyed Black anodize to not fade for at least six months or a year? What would be the absolute ideal aluminum alloy? Does temper of the alloy matter?

- Tucson, Arizona

November 7, 2013

A. Possibly.

All dyed anodize will fade if exposed to constant sunlight and certain fluorescent lights. Some lab cleaners can be a kiss of death for some parts.

We used a different Sanodal black dye with good luck.

I think that one key might be a thicker coat of anodize so it can absorb more dye which equals longer fade time. We used a very heavy coat because it did not really cost that much more and the rejects were few (and they were mostly caused by the operators).

Another thing to try if you are allowed is to give it a light coat of black lacquer. A couple of vendors support this site.

Finally, 2xxx and 7xxx aluminum is difficult to anodize as well as some of the others. Temper does make a difference, but we were not exposed to it that much.

- Navarre, Florida

November 8, 2013

A. For Milspec A-8625, it lists the dye required for compliance. The deep black MLW is the only one that complies. We have currently got testers in full Australian sun with monthly intervals over the past 16 months out of 7075, 6061 and 5005. Even at 16 months there is very little fade or discolour (no noticable change unless next to standard). Minimum layer thickness I would use for high UV exposure would be 20 µm. If your anodiser is good at their job, this shouldn't be an issue if you specify your requirement.

Daniel KingstonDNA Anodising - Brisbane, Australia

July 3, 2017

Q. Some anodized parts have color changes in customer usage environment.

1) the temperature is high, such as 200~300 °F (not exactly known);

2) Laser is used to clean surface dirty, which can cause certain temperature.

Question: what is temperature causing discoloration?

- Gilbert, Arizona, USA

May 12, 2019

Q, A, or Comment on THIS thread -or- Start a NEW Thread