Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Electroplating Plastic (ABS) Threads -- Tolerances

Q. My situation: I need to get multiple plastic (ABS) male and female threads electroplated. The product is using 2.315 inch -12UN- 1A and 1B (Male and Female) and 2 inch -12UN - 1A and 1B (Male and Female) and the set tolerances are around 200 Microns. If these threads get a 50 micron surface plating, will these threads even work, or will the plating just be torn off.

Will I have to completely redesign the threads, or lower the plating thickness? The plating is purely aesthetics to mimic metallic parts. These parts might be screwed and unscrewed a couple of times, but I don't want the plating being stripped off!

Would appreciate any help with this situation!

Engineer - Sydney, NSW, Australia

July 28, 2018

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

July 2018

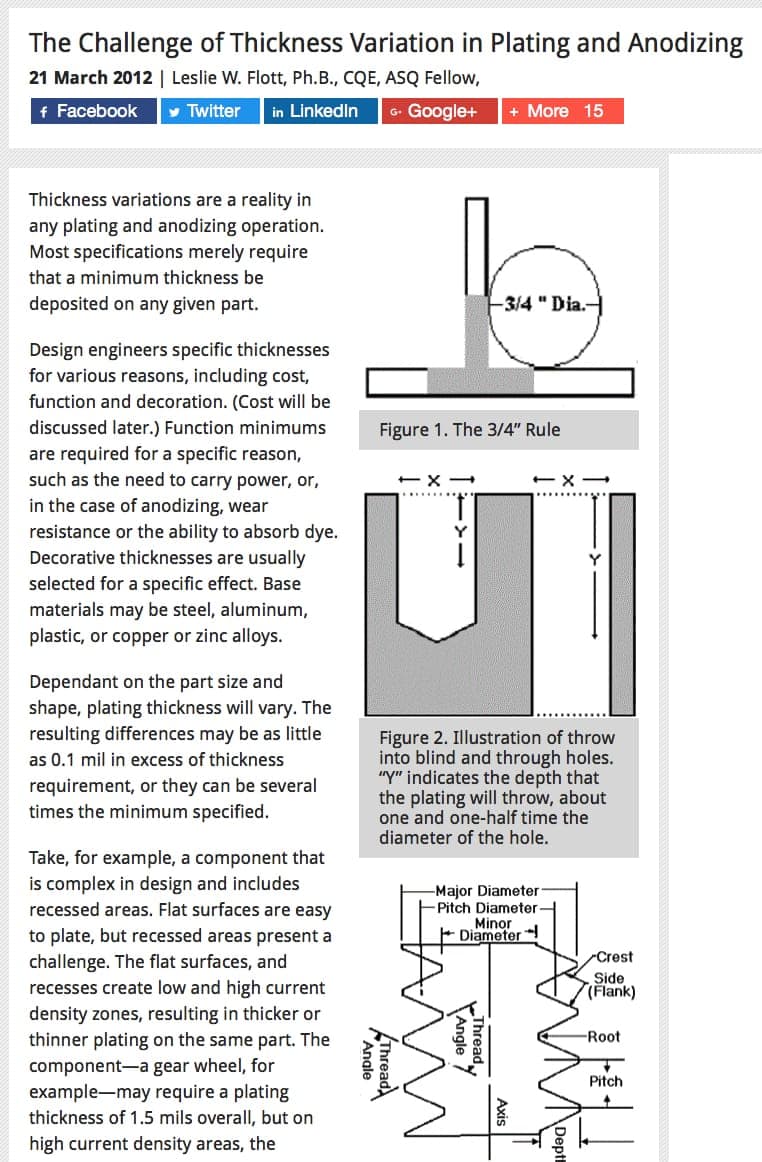

A. Hi Glenn. Plating on ABS plastic always begins with electroless processes rather than electroplating. They tend to give very even distribution. So, if you are talking about 50 microns of electroless nickel plating (and 10-20 microns might be more appropriate than 50), the build-up on the threads should be quite even. Even still the pitch diameter is increased by 4X the coating thickness as explained in Machinery's Handbook.

Ed. note: Sorry that page appears to no longer be maintained on materialstoday.com

If you want these parts copper-nickel-chrome plated 50 microns thick, the top of the external threads may get significantly more plating than the bottom, and the major diameter may increase by 6X to 8X the plating thickness, although I can't say precisely; please also see threads 2906 and 12211 and the linked article from materialstoday.com.

Electroplating of internal threads may not even occur unless the parts are racked with internal anodes. For these reasons I would suggest considering whether electroless nickel alone on all of the threads will meet your decorative needs.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 30, 2018

Q. Hey Ted,

Thanks a lot for the information!

The main purpose as stated before is purely for decorative reasons.

I need to colour match a couple of different metals:

-Machined aluminium

-Forged steel

-High carbon steel (Has that gentle rainbow colour hue through the metal)

-Copper

I need a "matte" finish colour on all the electroplated parts. If the ABS parts have a rough finish, will this be a dull "matte" finish once they are electroplated? I am struggling to find information of plastic surface treatments, e.g., machined effect on the plastic surface and how that will come out once plated.

Have you ever heard of Nickel coated ABS parts getting painted?

(This would be the ideal finish on 3 of the parts!)

Worst case with tighter tolerances, the plating in the high spots will be scratched or damaged?

Thanks for the input!

- Sydney, NSW, Australia

Q, A, or Comment on THIS thread -or- Start a NEW Thread