Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

Thread 453/01

Is Re-chroming as good as original

2007

Q. My company recently started to re-chrome some of our piston rods. My managers are asking if they will function the same way as the originals. I know different companies chrome slightly different, but when talking to them they say it will function the same, but because of liability they can't guarantee the work, because they don't know how the end user will use it.

QUICKSTART:

Some readers may wish to start with our article,

"Understanding Chrome Plating"

Second, we did an 8 hour test, but my supervisors want a functional long term test. is there a quicker way to do this test then waiting 1-2 years to figure out how they really function?

Thank you in advance,

Consumer - Cincinnati, Ohio

publicly reply to J. A. Marcus

QUICKSTART:

Although accelerated corrosion tests are actually not good predictors of actual service life because the corrosion mechanisms are different, it's generally believed that CASS testing (Copper accelerated salt spray) is more indicative for testing hard chrome than standard salt spray testing.

A. Hi J.A. It's a truism that something can always go wrong, but there are decades-old machine parts that have been rechromed so many times that people have lost count. So re-chroming per se can be just fine. But if you are generating internal rejects that must be stripped and replated in any volume, there is something wrong that might be able to harm parts, as well as burdening you with high costs. I think you need to work with a consultant or a highly trusted shop and develop plating/re-plating specifications that you can have confidence in.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

publicly reply to Ted Mooney

by Robert K. Guffie

on AbeBooks

(rarely)

or eBay

(rarely)

or Amazon

(affil links)

A. You should first strip-out the chrome and than chrome again wholly.

Re-chroming on already chrome plated parts is not going to be a good idea.

- Moradabad, UP, India

2007

publicly reply to Mohammad Kamaal

Multiple threads merged: please forgive chronology errors and repetition 🙂

Stainless shaft breaks after re-chroming -- hydrogen embrittlement?

Q. Have concerns over what the process of re-chroming has on the underlying metal. We have stainless steel propeller shafts that are chromed and every now and then the shafts are re-chromed. On one occasion we have noticed that the shaft has failed (broke in two), and have heard that the chroming company has had similar reports. I have read that during the chroming process there can be a hydrogen build up leading to hydrogen embrittlement of the stainless steel, and therefore lowering the strength of the steel. I was wondering if this is true, that rechroming does reduce the strength of the underlying material? and if so is there a rule of thumb that you can use to predict the life of the shaft given normal running conditions?

Shannon Orr- Australia

2005

publicly reply to Shannon Orr

by Polyanskiy & Belyaev

on AbeBooks

or eBay or

Amazon

(affil links)

A. Hydrogen embrittlement is a very real potential problem during chrome plating, however most experts believe it does not happen with stainless steel. Either way, your chrome plater can eliminate the problem by baking at 375 °F for four hours. Baking should be started within one hour after plating.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

2005

publicly reply to Jeffrey Holmes, CEF

A. The exact stainless grade makes a lot of difference in the susceptibility of SS to embrittlement. If they strip the chrome in an acid bath, it should be baked before it goes into the plate process as the etch is probably a greater source of the hydrogen embrittlement than the plate. It still needs the bake after the plate. There are lots of letters at this site discussing the problem. Do a search and be sure to go back a couple of years for the best ones.

James Watts- Navarre, Florida

2005

publicly reply to James Watts

Rechroming procedure

Q. I'm looking for the rechroming procedure because I have a part which already has been coated with chromium, but it's corrupted and needs rechroming again, can I get some help please.

Ahmed Moheb Ibrahim- Dubai,UAE

2007

publicly reply to Ahmed Moheb Ibrahim

QUICKSTART:

Our previously mentioned "Understanding Chrome Plating" explains the difference between hard chrome plating and decorative nickel-chrome plating.

If your interest is in decorative rechroming of consumer items rather than machine parts, please search the site for "Re-chroming", as there are many entries.

A. Is this decorative nickel-chrome or hard chrome, Ahmed? Rechroming is a little more difficult than the initial chroming because you need to remove the chrome and (if present) often the underlying nickel. Plus you need to apply experienced judgement as to whether the component is salvageable. If the component has been in service, then there may be significant mechanical work required (and if this is decorative plating, then mush buffing of copper may be required before you can begin the replating).

For stripping procedures, please see letter 29778, "NaOH vs HCl Chrome Stripping...which is better?". Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

publicly reply to Ted Mooney

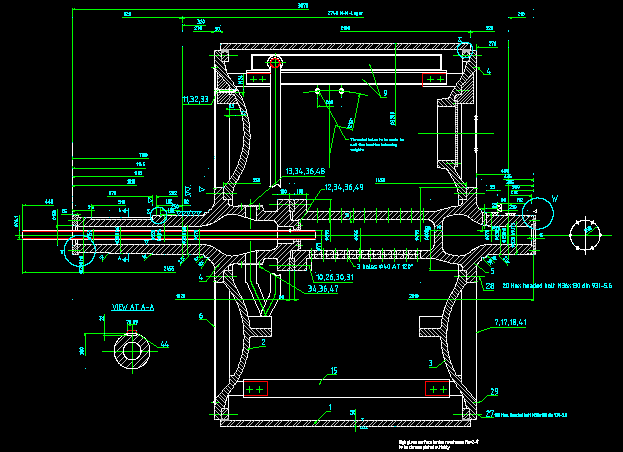

Paper manufacturer needs re-chroming service for a drying cylinder

2001Q. Gentlemen,

We have a hard plating drying cylinder of 3200 mm diameter and 2100 mm face length with a hard chrome plating of 50 microns thickness and micro finished to 2 microns Ra.

Now this cylinder developed honeycomb like structure within the chrome coating and is showing negative to dye penetration test.

Is it possible to repair the existing coating or renew the hard chrome plating on-site?

How is micro finishing carried out? Who can offer this kind of service?

I am herewith attaching autoCAD drawing of the cylinder.

Thank you,

Nagahari [surname deleted for privacy by Editor]paperboards, projects - Andhra Pradesh, India

publicly reply to Nagahari

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. This is not possible at site and will require honing or machining before re-plating -- which is possible. There are a number of people in Bangalore who can do this.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

2001

publicly reply to Khozem Vahaanwala

Q, A, or Comment on THIS thread -or- Start a NEW Thread