-----

Spray chrome (Chrome-look paint)

Quickstart:

Real chrome plating is used on truck bumpers & the grills of most automobiles. Please see our "Intro to Chrome Plating" if interested. Chrome Plating is an expensive premium finish, so alternatives have long been sought.

For high volume applications, vacuum metallizing has been used. This is the reflective aluminum finish which you see surrounding automotive headlights, but protected from the environment by the lenses. Clear coats may offer enough protection for non-demanding applications like interior brightwork.

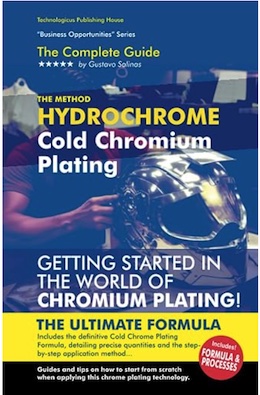

For low volume applications, "spray chrome" (chrome-look paint) can be used. This does not actually involve chrome, but is done with a base layer of paint, followed by a mirror layer produced by simultaneously spraying silver nitrate and a reducing agent, and is followed by a clear coat. Spray chrome and vacuum metallizing are actually quite similar, differing only in the middle layer.

There are also single-layer over-the-counter paints, but even the best of them look nothing like real chrome.

Q. I have a problem when using Hydrochrome on a motorcycle plastic fairing. I know the prep is good, and the base coat, but after silvering and tint coat you can see what looks like stains. After the silvering everything looks perfect.

I've attached a picture, desperate for some advice.

Thanks

Hobbyist - Lancashire, England

March 18, 2025

Tip: This forum was created to build camaraderie through sharing of tips, opinions, pics & personalities.

The operator & readers who are here for that often won't engage with anonymous posters.

⇩ Related postings, oldest first ⇩

Q. I am looking for an over-the-counter spray paint that approximates a chrome finish as much as can be expected. I am finishing a small 4" x 4" metal part.

Thanks in advance.

David S [last name deleted due to age of posting]hobbyist - Toronto, Ontario, Canada

2003

A. If you're looking for inexpensive "over-the-counter spray paint", you could try 'bumper chrome' ⇦ on eBay or Amazon [affil link] , David. From its name, you know they are trying to get the look right -- but one-component rattle-can paint will never actually approximate the look of chrome plating (although the much more expensive 3-layer "spray chromes" paints can look pretty close. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. I agree that most spray commercial spray paints don't approximate chrome. This has to do with the differences in surface architecture between a plated surface and a conventional metallic pigment. (bounce angles of light, uniformity, dispersion, etc.) However, there is a new generation of coatings based on VMP (vacuum metallized pigments) that do in fact approximate chrome. You see this in the automotive industry as many of the interior chrome parts are now a coating instead of conventional chrome.

Frank Thomas- Cleveland, Ohio

![]() Thanks, Frank. Vacuum metalizing of auto interior parts may be improved but it's not new. The armrests, window cranks and dashboard parts of many 1960's automobiles were vacuum metallized plastic. It wore off quickly and exposed ugly mustard color plastic parts underneath.

Thanks, Frank. Vacuum metalizing of auto interior parts may be improved but it's not new. The armrests, window cranks and dashboard parts of many 1960's automobiles were vacuum metallized plastic. It wore off quickly and exposed ugly mustard color plastic parts underneath.

Car buyers mistakenly thought this stuff was "chrome plating", which gave chrome plating of plastic an undeserved bad name. Actually, real chrome plated plastic is used on the grills & exterior parts of most cars & trucks today, and it stands up to decades of sun, salt, ice, gravel hits, and car washes.

I believe you that vacuum technologies are better today than in the 1960's, but to the extent that we can, we're trying to not let the public be fooled by a cheaper technology and ruin chrome plating's reputation a second time :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

I am looking for a paint that is chrome that I can use on plastic parts. I was wondering if anyone knew where I could find some. Thank you!

Erin Stephensonhomemaker - Lakewood, Washington

2004

I think you know this, Erin, but to prevent this posting from confusing others, let me start by saying that paint is not chrome.

There are paints that range from spray cans in the $5-$10 range, to paint systems that are a pretty good imitation of chrome but cost more like $150 for a tiny quantity and require training, skill, and great care in their application. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. So, IS there any chrome spray paint that will come 'extremely close' to approximating the look of chrome plating? I did find a product by Alsa Corp. but wow...$150 for 8 oz! I would be willing to pay $50 for 8 oz. as long as I get a good finished look. Any suggestions as to what to use or where to get it? Thanks.

Ray Henry- Hollidaysburg, Pennsylvania

2004

A. Hi Ray. While the vendors of high quality chrome-look paints apparently originally wanted it to be a technology they'd offer to OEMs and established shops, it caught the consumers' imagination and it just made more sense to sell it to a clamoring public than to restrict it to major finishing shops. Also, the technology has improved rapidly, and it is easier to apply. So earlier answers you see on this forum are somewhat out of date.

But I'm sure you only get what you pay for, and how far does 8 ounces go? Compared to the price of real chrome plating, even the most expensive chrome-look paint is dirt cheap 🙂

Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Concerning the question of chrome Paint and the claimed suppliers of such a product, I have extensive experience with a product called [deleted by editor] and a product called [deleted by editor]. First, [the first brand] is neither user friendly nor is it near as durable as suppliers of this product claim. After a substantial investment for equipment and the product itself a person can produce a sprayed on chrome finish on just about anything. The problem is this finish does not last more than six months, it appears to start discoloring most of the time around the edges (but not always) and eventually just peels right off the substrate. I could go on for some time about the poor quality of this product but I think it will suffice to say that this product does not work more than a very temporary basis. The supplier of [the first brand] will not confirm the shortcomings of this product if confronted, but just remember they only need to sell you the system and the supplies once and they have just made good money off one more sucker.

[The second brand] is considerably more user friendly and much more cost efficient. If applied properly it looks very much like chrome until it is top-coated at which time it's reflectivity is reduced to about 85 to 90 percent. This a very nice effect to have in your bag of tricks as a custom painter, but if you're looking for a chrome paint to replicate the look, feel, and durability of chrome plating, such a product does not exist. -- Just the truth.

- Dallas, Texas

![]() Thanks, Larry. Yes, chrome plating is the application of very hard, slippery, corrosion resistant and abrasion resistant metals. You're right that no paint offers what a layer of real chrome metal offers. Chrome plating been the premium decorative finish for over 75 years.

Thanks, Larry. Yes, chrome plating is the application of very hard, slippery, corrosion resistant and abrasion resistant metals. You're right that no paint offers what a layer of real chrome metal offers. Chrome plating been the premium decorative finish for over 75 years.

But we ask that people not offer testimonials or slams here (huh? why?).

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

One-step or Two-step Chrome Paint?

Q. Does anyone know of an automotive one-step or two-step paint mfgr. chrome that looks pretty real?

Jon Eckaircraft maintenance - Hebron, Kentucky, USA

2004

A. Hello Jon. The chrome colored paints in a spray can don't look much like chrome plating to me.

But the high end, proprietary, 3-step systems (primer, silver nitrate

⇦ on

eBay or

Amazon [affil link]

& reducer, clearcoat) that you can buy today do look a lot like chrome.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. The best paint that I have found in a spray can is Chrome paint from Seymour ⇨

Now, don't try to clear coat these chrome colors as the "chrome" would turn grayish and loose all reflectivity.

custom mill - LOS ANGELES, CALIFORNIA, USA

2006

I purchased the Seymour Chrome Paint and it was slightly better than the Walmart shelf brands and would not work on a bumper, or anything that is made out of Chrome, Silver plate, etc., so don't waste your cash ... there's no reflection like the real thing ... it actually looks like a primer. Beware,

I purchased the Seymour Chrome Paint and it was slightly better than the Walmart shelf brands and would not work on a bumper, or anything that is made out of Chrome, Silver plate, etc., so don't waste your cash ... there's no reflection like the real thing ... it actually looks like a primer. Beware,

- Wethersfield, Connecticut

April 29, 2008

A. Rust-Oleum® Bright Coat Metallic Chrome Finish Spray Paint ⇨

BOND PYANT- Cleveland, Ohio, United States of America

November 25, 2017

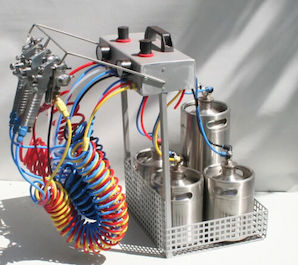

RFQ: I am currently looking for companies who provide an alternatives to chrome plating and who sell the equipment and the chemicals to reproduce the chrome-like affect. I have researched many web sites and many companies and have had minimal results. The only two so far are Alsa Chrome FX, and Gold Touch [a finishing.com supporting advertiser] Cosmochrome. I'm sure there are more companies out there with similar equipment. If any knows of anything I would appreciate It dearly.

Thanks,

Wade J Cleziemotorcycle/hobbyist/business owner - Pocatello, Idaho, USA

2003

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q. I am looking into purchasing one of the paint-on chrome systems. We are a powdercoater and have a good reputation for durability. How does it hold up to heat, maybe on engine parts. Any experience with chip resistance.

James Ewing- New Cumberland, West Virginia, USA

2007

A. Hi James. Each time we've posted inquiries about satisfaction with chrome-look paints it degenerated into people saying something like "Brand X is fabulous, brand Y is worthless". If anyone offers generic answers that apply to all chrome-look paint we'll be happy to print them -- but you can understand how printing "testimonials" from anonymous posters in a public forum gets silly quickly :-)

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Let me take it one further. There is a banner at the top of this screen with companies that support this site. Talk to their sales and ask the same questions. Then ask for lab testing reports on the one that you like best after the initial conversations.

James Watts- Navarre, Florida

I'm a newbie to your site and would like to thank all of you for offering great info.

Does anyone have any experience with the chrome spray on finishes? The 'automotive finish' works for my application, but I question if it carries and hold the lustrous finish as traditional chroming.

Thanks in advance for the help.

Hobbyist - Sioux Falls, SD, USA

October 3, 2008

Hi, Drake. Chrome-like spray paint is better than it was even a few years ago. It's safer, easier, and much cheaper than real chrome electroplating ... but OEMs don't use it, which should answer your question.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

!! If you want REAL Chrome in a can you will find it at Alsa. Killer Chrome is REAL Chrome broken down in a spray form. I will forever use Alsa Corp's paints. Check the site out.

Sandi Propst- Ponte Vedra, Florida

December 9, 2009

A. Hi, Sandi. I'm glad that you're pleased with the look of spray chrome, but be thankful that the shops who chrome plate the landing gear of airliners know better than to believe that chrome-look paint is "REAL Chrome broken down in a spray form". There would be no survivors from the first flight.

Chrome-look paint is NOT chrome -- it has nothing at all to do with chrome; chrome is an electroplated layer of the element chromium, 100 percent metal, "grown" onto the substrate by electroplating for perfect adhesion. Chrome-look paint is simply a paint job trying to look like chrome, not to perform like it.

I am not knocking chrome-look paint at all! It pleases me that hobbyists are using chrome-look paint instead of fooling with toxic carcinogenic hexavalent chrome plating solutions! I am simply saying that we mustn't pretend that it is chrome plating; it has nothing in common with chrome plating except shininess.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I have read over the chrome "paint" vs. Chrome "metal plating" - I am looking for a product that has the depth and shine of chrome for use on plastic scale model replicas. I am familiar with Alclad II ⇦ on eBay or Amazon [affil link] metallic finishes for hobbyists, but want something a little more touch resistant and durable "appearance" only. There is no requirement for the other advantages of real chrome. Thank you - John

John Ballhobbyist - Tucson, Arizona

February 25, 2010

A. Hi, John. Any of the major brands of chrome-look paint should be fine. What is required for durability is that, after the very thin layer of silvering or aluminum flake, that the paint system include a durable clear coat to cover and protect that metallizing from rubbing off easily.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I understand the actual difference between chrome and chrome paint. I also understand that real chrome finish is superior to paint. I need to chrome paint a part but am concerned with longevity, so my question is this, if the painted piece is not handled once installed and is not exposed to the elements should I be concerned with longevity? It will be exposed to direct sun as there is a clear lens over it, but that is it.

dan smith- morton, Illinois, united states of america

August 3, 2010

A. Hi, Dan

I personally would not expect this to be a problem. Some outdoor "statues" like the "chrome" jaguars on the marquees of Jaguar dealers are chrome-look paint. Further, much of the shiny stuff on cars, but behind clear protective plastic (like headlight reflectors) are not chrome plating but vacuum metallized (which is very similar to chrome-look paint). Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Sir,

We are a manufacturer of injection moulded plastic components. Now we are manufacturing decorative and deities figures. Now we are getting plating done in Vacuum chamber process. As some products are bigger they are not fitting into chamber. Will you please suggest any other type of gold color plating like dipping process or spray coat and their availability? Now we are using HIPS & ABS. Please help.

with regards,

polymers - Hyderabad, A.P., India

July 28, 2012

A. Hi G.V.

"Chrome-look paint" is actually very similar to vacuum metallizing. Both start with a base coat; then they have a bright layer of either aluminum deposited in vacuum, or aluminum deposited by spray painting the carefully designed tiny flakes, or two-part silvering; then they have a clear top coat applied. It will probably be very hard to tell one from the other.

I think the biggest difference between vacuum metallizing and high quality chrome-look paint is simply that the vacuum metallizing will involve much higher capital cost (because of the need for a vacuum chamber) but significantly lower labor cost (because the vacuum deposited aluminum easily and automatically covers hundreds of components, whereas spraying requires care and handwork one piece at a time); therefore the selection between the technologies would be based primarily on production volume rather than appearance or quality.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I found some ceramic piggy banks in a colored chrome (or chrome-like) finish, but they only seem to come shades of pink & red ... I would like to find some in blue and/or green and/or yellow. Barring that I would like to find a paint or finish in those colors and finish my own banks. Can somebody help me?

d covey- riverside California USA

September 16, 2012

A. Hi D. You may be able to just put a translucent blue lacquer or alcohol-based metal dye or vinyl dye on top of the existing piggy banks to change the color. Otherwise, see the banner at the top of the page for sources of tinted chrome-look paint.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I am wondering if there is a viable way to get a faux chrome finish on a few cast aluminum sculptures. Nickel plating is, as far as I know, the only plating process for aluminum and it is out of my price range. The sculptures in question have been evenly sandblasted, but their surfaces are irregular. Perhaps I can apply several layers of polyurethane to smooth out the rough surface created from sandblasting and then apply an aerosol chrome-like finish? Extensive polishing between coats is pretty much impossible since the castings are full of undercuts and hard to reach areas.

How do you suggest I approach this?

- Nokesville, Virginia, USA

February 11, 2013

A. Hi Caleb. We appended your question to a thread which should answer it. High quality 3-layer chrome-look paint should give you the faux chrome look you are seeking. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Chrome, Gold and Brass accents on Mid-Century Radios? Many radios and record players have thin edges and other detail like dial numbers that have a shiny chrome, gold or bright brass finish. After 50 - 60 years some or all may have come off. I'd like to restore these to the original look. Bright-finish paints don't seem to have the original luster. Any suggestions as to products and techniques are appreciated.

Chester DwarsHobbyist - Largo, Florida

May 8, 2013

A. Hi, Chester. First, are these accents on plastic or metal parts? If the parts are metal, they probably have real electroplating and the parts can be sent to a plating shop for replating if you wish. If the parts are plastic, it is probably not real electroplating but vacuum metallizing (a basecoat, followed by a very thin layer of vacuum-deposited aluminum, followed by a clear coat or a gold/brass tinted translucent coat).

Rather expensive machines are required to do vacuum metallizing, but today's "chrome look paints" are essentially the same 3-layer thing as vacuum metallizing except that the shiny layer is applied by spray painting.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

[editor appended this entry to this thread which already addresses it in lieu of spawning a duplicative thread]

Q. I saw a show about restoration that featured how to spray an enamel on the piece and then pour a liquid over it and it turns to a chrome. What is this called and where can I buy it?

- San Angelo Texas

June 25, 2014

A. Hi Deborah. Virtually every type and brand of "chrome look" paint has been on a car show by now. None of them are magic, but the results are proportional to the cost, the required effort, and the skill in application.

All of the better looks come from 3-step systems which consist of:

- A base coat / primer designed to leave a very smooth surface while providing adhesion.

- A reflective layer consisting usually of either --

- A clear paint with very tiny and thin aluminum flakes that lay down flat to produce a reflective finish or,

- Simultaneous spraying of silver nitrate and a reducing agent, which creates a thin silver metal film and is essentially the same process by which mirrors are made (Brashear process).

- Application of a hard clearcoat paint topcoat that protects the reflective layer from rubbing off, while not yellowing or dulling very much.

If you pay a lot for each layer, so it's really optimum, the results can be pretty good. This is offered by Alsa, Chrome Solutions, Gold Touch [a finishing.com supporting advertiser] ("Cosmichrome"), G.J. Nikolas [a finishing.com supporting advertiser] ("QuickSilver"), New Fantachrome, Spectra Chrome, and probably many others. Google "chrome-like paint" or "chrome-look paint" or "spray chrome".

When you say "poured on", I suspect the part that was being painted was on a "spin table" not too different than kids' "spin art"; the idea is to use centrifugal force to ensure a thin and even coat. I've seen a similar process in the metalizing of lacquer record masters for vinyl records.

Probably a bit less expensive and easier are systems like Alclad II

⇦ on

eBay or

Amazon [affil link] -- see letter 15869 for more description and youtube video.

But you need to determine whether it's for interior or exterior use, the anticipated production volume, and issues like that before you can decide the best approach.

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I have chrome strips on the door panels of my car that have been worn through. Will chrome spray kit work? The strips are molded or glued to the vinyl Thanks, Al.

Alan Troxell- crawford Colorado

July 29, 2014

A. Hi Chris. If there is actually a hole, paint won't fill it. If you mean that the finish is worn off, yes it can probably be painted, but best results come from best application situations, so it is not ideal to do it in situ. A photo would help; it's not completely clear that you are talking about an interior trim item molded or glued to a vinyl door liner, as opposed to the trim on the exterior of the door. But prepping the metal or plastic for paint is just as important, or more so, for chrome-look paint as for any other paint. Without proper prep the paint will peel; so it's important to know exactly what you are trying to paint. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I need to chrome plate a PCB in order to make it shiny and reflect most of the light falling on it. I tried the chrome spray; it works good, but finishing is not proper.

I was told that there is a preprocessing layer of some spray, then chrome spray and then some shiny polishing is to be done. But exact procedure and components were not known.

Can anyone help me out? The finished PCB is not smooth and not as shiny. What shall I do?

embedded engineer - Gandhinagar, India

April 14, 2015

A. Hi Ashok. To my knowledge all of the major high quality chrome-look paints involve those same three layers: a smoothing base coat, the "chrome" layer per se, and a clear topcoat to protect it. Whoever you bought the chrome-layer paint from probably also offers the base coat and the top coat. See the banner ad at top of page for a couple of brands.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

April 2015

Aluminum nitrate as silver nitrate replacement for chrome-look paint

Q. Can I use aluminum nitrate to replace silver nitrate for chrome?

Lito domingo- NAVOTA CITY, Philippines

May 26, 2015

A. Hi Lito. I've never heard of it myself, and strongly doubt it. What would lead you to believe it could work, and what would you propose to use as the reducing agent? Thanks.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hi ted. I thought I might substitute aluminum nitrate due to the expense of silver nitrate. I have just watched on YouTube and I saw how the glass was made silver using silver nitrate, but silver nitrate is expensive so I thought you might substitute aluminum nitrate. Is it possible by the same process. Hoping for your response.

Thank you

- NAVOTA CITY, Philippines

A. Hi Lito. Although silver metal and aluminum metal are both shiny, they have almost nothing in common chemically and metallurgically. I am unfortunately pretty confident that there is no known way to reduce aluminum nitrate to a shiny aluminum metal.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Hi Lito,

Silver nitrate is used because silver (as a "noble metal" as it is) tends to be in a metallic form. So, you can find silver metal in the nature because of this behaviour.

Aluminium is not a metal found in nature as a metal itself, only in minerals. To produce aluminium, you must use electricity to force the aluminium atoms to meet in a metal structure.

Silver, in a nitrate, tends to form silver again. That is because of its "noble metal" behaviour. Aluminum tends to remain as a nitrate or to form oxides or salts. Sorry, but it's not an alternative!

This trend is known as "reduction potential", and noble metals have a positive reduction potential. Aluminium has a very low reduction potential, negative, so it does not appear as metal in nature.

Hope this answers your question!

Regards,

Daniel

- Cañuelas, Buenos Aires, Argentina

Which Chroming Process for Pitted Vintage Boat Hardware?

Q. I'm restoring a 1959 15' runabout boat. I'm curious as to which process is best to "rechrome" the hardware - bowlight, cleats, etc. (10 pieces). Some say the nickel-chrome process -- which is extremely expensive - others say the silver-based(?) re-chroming, which is far less cost. The boat is not kept in water and is used mostly for show -- not show quality. Please advise in layman's terms which is better and why.

Rick PariserBoat Restoration - Great Falls, Virginia

October 16, 2015

A. Hi Rick. We added your inquiry to a thread about the subject. In brief, yes, high quality chrome plating is terribly expensive but the "silver-based" process is just "chrome-look" paint rather than real plating. If it's done well it will probably hold up reasonably well on a fresh water or show boat, although the lines will wear away the paint if the cleats are used much.

Correcting the pitting is a monstrous labor problem for real re-plating, where grinding plus soldering or brazing are required on every tiny pit; it's much less of a problem for chrome-look paint, where body filler can probably be used.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Thanks for immediate response BUT the use of Chrome Paint is NOT what my question is about. I'm more interested in comparing and/or your recommendation on Nickel Chrome process vs. Silver Process to re-chrome boat hardware such as cleats, bow lights, handles, etc.

Rick Pariser [returning]Boat Restoration - Great Falls, Virginia

October 16, 2015

![]() Ah, but it is, Rick :-)

Ah, but it is, Rick :-)

Please read our "Intro to Chrome Plating" and it will hopefully be clearer. Your "silver process" refers to the better quality chrome-look paints which consist of a base coat, followed by two-part silvering (as is used to make mirrors), followed by a clear coat.

some of the vendors of these chrome-look paints call them spray chrome, silver chrome, or chroming -- but they are not "chroming" except in the very limited sense of making something look like chrome. Sorry, but they're paint.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I found this discussion interesting and useful, thanks. I have taken from the discussion the fact that most chrome or highly reflective paints I can purchase will be based on aluminium flakes and also that vacuum metallisation although an entirely different procedure has close parallels in view of what is produced rather than how.

My application is hand made artisan lighting products. I don't require a traditional smooth chrome finish, I prefer a degree of surface texture and this compliments some of the textures left in the metal itself by the manufacture process, which are seen as attractive evidence of a craft rather than mass produced perfection in addition UV and handling are not an issue.

My primary concern is simply whether such paints can be expected to dull or tarnish over time. At least now I know that this question will boil down to something like -

Is it realistic to expect polished aluminium flakes to remain bright under protective coatings?

and

Is there anything in the paint that might cause discolouration in the first place?

The last bit may sound perverse but I have heard that tarnishing of copper plate has been associated with slight, partial breakdown of applied resin based protective layers on initial exposure to UV rather than an failure in the protective skin allowing oxygen in - not sure if this is conjecture or demonstrated.

For copper plate I use benzotriazole

⇦ on

eBay

or

Amazon [affil link]

before any protective coats, comparison of "twinned" test samples suggests to me it is pretty effective.

- Saltum Denmark

December 28, 2015

A. Hi Jon. Yes, the new generation of high quality "chrome look paints" and "vacuum metallizing" generate coatings that are very similar in makeup and performance, with the biggest factor in selecting between them just being production volume -- with "chrome look" spray painting requiring more labor and attention, but not involving the million-dollar capital costs.

In either case the question is whether the elements can be practically kept away from wreaking slow havoc on the shiny layer. Silvered glass (mirrors, thermos bottles, etc.) or aluminized plastic can last many decades when sealed away from the environment, and I believe that most automobile headlight and taillight surrounds and reflectors (sealed behind glass or plastic) are vacuum metallized.

But I believe that the clearcoats for metallizing or chrome-look painting have a limited life when exposed to UV and difficult environmental conditions, and that it's a major struggle to make a clearcoat both impermeable and non-yellowing -- such that we still can expect only a limited life from such parts. I welcome other opinions, since mine are more book knowledge than actual experience, but we have an extensive thread on just that subject: Thread 27758, "Mirror finish spray chrome - topcoat yellowing".

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I'm restoring a '58 Packard. The gauges have a plastic face with the letters and numbers engraved into that plastic. The letters, numbers, and center "button" that covers the origin of the needle behind it are filled with a "bright chrome gold". I haven't found anything to give me that luster. I'm not sure what process they used in '56 - '58 for the gauges. This problem is my only major obstacle for restoring this car.

Thanks,

Buddy Crofton

- Rio Rancho, New Mexico

February 9, 2016

A. Hi Buddy. I wouldn't know what the process was, but would probably guess at vacuum metallizing.

Obviously you're not going to be able to do that, but you might consider gold leaf.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Back in those days the process they used was vacuum metallizing. If the new gauges that you are installing are already chrome plated and it's true nickel/chrome, you could use a small gold brush plating kit. Now if the new gauges you are using are again vacuum coated, but it's not gold but silvered colored, you could use a gold tinted clear coat that will give the appearance of gold plating.

Marvin Sevilla- Managua, Nicaragua.

Q. I am facing Problem in touch up of Alloy wheel in machined area, where the scratch is up to the base metal.

Any touch up system is available?

- Chennai, Tamil Nadu, India

June 22, 2016

A. Hi srinivasan. To the best of my knowledge there is nothing you can do to repair a damaged nickel-chrome plated wheel short of removing the scratch, stripping the chrome, re-activating the nickel plating, and nickel and chrome plating it again.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I have a 1967 Ford Fairlane XL. I was wondering what is a good inexpensive chrome paint to use on the plastic dash shroud to refinish it? Thru the years it has all worn off and the shroud is brown and unsightly on an otherwise award winning car.

Danny Breeden- Martinsville, Indiana USA

August 26, 2016

A. Hi Danny. Chrome is a metal that is deposited by electroplating. To get a paint to look somewhat like it is not a simple one-step process, but is 3 separate coats as a minimum: a smoothing base coat, a very thin aluminum or silver metallizing layer, and a clear top coat to prevent the metallizing layer from instantly rubbing off or oxidizing to dullness.

The first coat has to be designed for super smoothness or you'll never get reflectivity; the second coat is pretty high technology; the third coat must stay clear without yellowing, offer UV resistance, be fairly hard, and be impermeable to keep the metal from oxidizing. Thus, when you ask for inexpensive chrome-look paint, it's a bit of an oxymoron: an expensive 3-coat paint system may look like chrome, or the vacuum metallizng that it probably was, but an inexpensive single coat system never will. See the banner ads at the top of this page or google for "spray chrome" -- sorry, we don't compare brands here (huh? why?). Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hi, has anyone in this forum tried rechroming their chrome pieces themselves? I know the solutions are pretty toxic, but I understand it can be done, providing the toxic substances are disposed of lawfully. Just wondering how difficult this process is. I have a '69 Cougar XR7 that I'm restoring with some severe pitting on the chrome. To pay for the rechroming would be crazy expensive. Just looking for a reasonable, durable and attractive alternative to hiring it out.

Michelle Schneiter- Agoura Hills, California USA

February 1, 2017

A. Hi Michelle. Yes, rechroming is fabulously expensive because of the almost countless hours of highly-skilled labor required -- I'm not referring so much to carrying the part to the chrome tank as the grueling precise drilling out of every pit followed by welding, brazing or special soldering to repair it. You don't seem to be talking about an authentic restoration for car show competition, but just something nice, so you could try the chrome-look paint we've been talking about. We've linked to our FAQ on Chrome Plating near the top of this page and I think you'll find it informative.

If I haven't quite answered your question, put "chrome plating at home" into our search engine and you'll find at least three long discussions about it. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. There are many ways to skin a cat and in your case using Nickel should be a very good alternative to chrome, it's readily available as hobby kits, the tricky part in your case it that it seems that your piece is pot metal and is badly pitted, I have restored these type of articles successfully without having to do the extensive prep work required to plate nickel directly on the pitted pot metal (sand blasting, cyanide flash copper, filling the pits with solder, cyanide copper, acid copper, Nickel plating).

What I do is I send the part (or do it myself when I have the time), to a painting specialist and have the item prep to the primer base (fill the pits with putty, self etching primer, sanding primer), when I make sure that the piece is in perfect shape I coat the piece with conductive copper paint (allow to dry for 24 hours), and plate the now conductive piece with a thick coating in the acid copper plating tank (4 hours), and polish the piece to a mirror finish -- this piece is now ready for Nickel plating bath.

- Managua, Nicaragua

Ed. note: Thanks Marvin! You are continuously a great helper for our readers.

[editor appended this entry to this thread which already addresses it in lieu of spawning a duplicative thread]

Q. Mr. Mooney,

First, you are to be congratulated on your attention to this thread! I have built models (1/8th scale) of boats of the 1920's and '30's and all have chrome or nickel plated hardware. I am 81 years old and am trying to "finish" a 1926 boat model I started in 1988 but have been stymied by how to get a nickel plated look on the tiny pieces of hardware that go on this boat. Most of the pieces I have created are made of brass but some are made of hard wood. I have been disappointed in the results of the "chrome" spray paints found at most home supply stores. I have even tried a stick on chrome paper-like surface that doesn't provide adequate results. Any suggestions for a spray paint that come "close" to the nickel plating used in the 1920's?

NA - Bradenton, Florida USA

May 30, 2017

A. Hi Mo. Brass is probably the most easily plateable substrate material. If you've been stymied for 30 years looking for realistic paint, maybe it's time to bite the bullet and try nickel plating. Once you've got the process down on brass, you can try to paint the wood pieces with some graphite or copper based paint, as described by Marvin Sevilla just above, in order to nickel plate them as well.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

![]() Ted -- Thank you for your response! I was doubting you'd still be monitoring this site and I'm pleased you are. I have purchased a chrome plate paint that was recommended on several sites and will see how that works. I am not in a position to actually have these miniature pieces nickel plated, although that was what was used in the early 20's. Thanks - you have a great site.

Ted -- Thank you for your response! I was doubting you'd still be monitoring this site and I'm pleased you are. I have purchased a chrome plate paint that was recommended on several sites and will see how that works. I am not in a position to actually have these miniature pieces nickel plated, although that was what was used in the early 20's. Thanks - you have a great site.

- Bradenton, Florida USA

A. Hi Mo,

I recently saw all sorts of home electroplating kits on Amazon.com.

If you go to Amazon and search "nickel electroplating", you can also find various reagents and so on, but the "brush on kit" is easier, and probably not much more expensive, than figuring out how to hack a Wal-mart and buy all the necessary tidbits ;)

They also have electroplating kits for applying silver, copper, gold, and so on.

I hope that helps!

- Katy, Texas USA

Ed. note: Thanks for your help, Kris! Apologies that we had to delete a few lines from your posting: As part of our agreement with Amazon, we're forbidden to post any of their prices on our site. We also have been specifically requested by the vendor you mentioned not to post their name on this site.

A. Try Bare-Metal Foil (https://www.bare-metal.com/)! Bare-Metal® Foil is perfect for duplicating chrome or nickel on model cars, model trucks, and model aircraft, etc. Made in USA!

Hope it helps and good luck!

- Zagreb ,Croatia

December 13, 2017

Wanted Electroless Coatings for Zinc and Tin-based Pewter

RFQ: We operate a zinc & tin jewelry casting business for the movie industry in San Marcos, California between Los Angeles and San Diego. Ideally, we would like to apply coatings to our zinc or tin based pewter castings without electroplating them using hazardous chemicals. The finishes we want include nickel, chrome, silver, gold, copper, brass, bronze and a few others. We also can use shiny or oxidized finishes which are frequently called Ox or Antique. If you have any suggestions or recommendations based on personal hands-on experience, I would enjoy hearing them.

Richard KutnerCalifornia Custom Casting - San Marcos, California

July 10, 2018

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Hi Richard. I think "chrome-look paint" with different translucent lacquers to give other metallic looks might be just what you need. See the ads at the top of this page. There may be other approaches, and readers are encouraged to offer them (non-commercially).

P.S. Apologies, but the part of your posting asking for testimonials was omitted. People can contact you privately but we can't publicly post testimonials ( huh? why?) :-(

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Nickel-chrome plating vs. silver nitrate finish

[editor appended this entry to this thread which already addresses it in lieu of spawning a duplicative thread]

Q. Hello, sir, can you teach me how to paint iron with silver nitrate?

The difference between silver and nickel chrome

educational - homs .syria

August 21, 2019

A. Hi cousin Albaraa. We added your posting to this thread which already addresses your subject. 'Nickel chrome' plating means electroplating a layer of nickel metal on the object followed by a layer of chrome metal; the two work together to produce a shiny, corrosion-resistant, tarnish-resistant, hard metal coating on the object. We have an "Introduction to Chrome Plating" here which you might find interesting.

If you only need the "look" of nickel-chrome, but don't really need the properties of a metal coating, you may be able to use "spray chrome" chrome-look paint; it's easier, less toxic, and less expensive. Chrome look paint consists of three layers, the first is just a smoothing basecoat. The second layer may be a very thin layer of silver which is achieved by simultaneously spraying a solution of silver nitrate (dissolved silver) and a reducing agent such as formaldehyde and sugar. The reducing agent causes the dissolved silver to become a thin layer of silver metal. This process has been used for a long time to make glass mirrors, and is called the Brashear Process. The silver is very thin and would be easily rubbed off, so the third layer of the system is a clear coat to cover and protect the silver. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Clear coat peel off problem from spray chrome/hydrochrome

Q. Can anyone suggest which type of clear coat can be used to seal the silver from spray chrome/hydrochrome process. Right now I am using automotive 2k PU clear but it does not having good adherence to the deposited silver and peel off easily with slight scratch.

I have tried many type of 2k PU clear but doesn't get the good adherence.

Note: In this spray chrome process I have also tried to use the same base clear (below silver deposition) and top clear (above silver) but still the peel off problem is there.

Hobbyist and Shop owner. - India

April 24, 2020

Ed. note: We have a whole long thread just on the topcoat: Thread 27758, "Mirror finish spray chrome - topcoat yellowing".

Q, A, or Comment on THIS thread -or- Start a NEW Thread