-----

Spray chroming with silver nitrate

< Prev. page (You're on the last page of this topic)

Q. Hi, thanks Andy Tan for reply..

Team, please help to make perfect silver mirror solution 1 l.

getting confused in.. AgNO3+NH3+KOH

rcho+OH and other.

How much is this require for. Suggest me the quantity, both the mixtures; please suggest quantity grams required for all chemical and steps. I will be grateful to you.

- Delhi, India

March 23, 2017

Team please help. 2nd request/

sameer haque- Delhi, India

March 28, 2017

A. Mr. Sameer Haque, when you first published your question about the issues you had with high surface tension you were having with your PU base for the Spray On Silver process, I believed that you had figured out the process and the chemicals, but it seems that you are starting from scratch.

Let me tell you my story in hopes it may help you in the long run.

When I first saw a video of "Spray On Chrome" done by one of the big players in the industry, I was beside myself, amazed, it all looked like magic and I made up my mind that I wanted to do this as a business. Then I found out just how expensive this can be, but I was not discouraged, I thought that maybe if I could get myself the basic chemicals I could make it big, be the first Nicaraguan in this business.

After learning that spray on chrome was really just silver spraying, I dedicated countless hours learning just the basics (I had not found this very helpful forum); I purchased expensive Silver Nitrate, Sodium Hydroxide, Ammonium Hydroxide and inverted sugar (table sugar and citric acid

⇦ on

eBay

or

Amazon [affil link] ), the basics of Tollens' reagent; it all worked very well in test tubes made out of glass. I said to myself that I was ready for testing on properly prepared plastic pieces (plastic spoons), but nothing --nothing-- was working; the chemicals were not staying on the spoons, and I kept wasting precious time and money. Things were not looking good; I was desperate and only myself to blame because of the countless variables, but I was too dumb to know when to quit.

It took me about 6 months to save enough money to purchase and bring silver mirroring chemicals (spray on chrome chemicals were out of my league), surely this time I would make it ... Big and Success was a matter of time. I got the chemicals, I had the plastic spoons ready, but things didn't go as planned; I was able to Silver the spoons, but I had issues with the basecoat and clear coat, they were interacting with each other, ruining the test pieces. I was very disappointed, but progress was made nonetheless.

I gathered up strength and money again for one last try, the third one had to be the charm right?, I learned that automotive clear coat was the best (albeit it introduced higher surface tension as opposed to single component enamels that were more glass-like in nature). So I purchased a wetting agent, automotive base/clear coat and chemicals from trusted Mirroring company (they didn't know anything about spray on chrome yet so no hope for tech support). Wow! I was very impressed with the results, beautiful first surface mirror on properly prepared plastic spoons (simulating a future working piece), but I was not out of the woods yet; as impressive as the silver mirror was, my next and last obstacle to success was the top coat -- it turned all of my working pieces to yellow tone; I was in trouble: unless my future clients wanted colored chrome (which I did plenty in blue, gold, red), I could not make the pieces look like real chrome. I tried ever single cleat coat available and none worked, I was really disappointed. After a few years of research, a lot of money invested, time wasted, sweat and tears all for naught, but I was too close to success to give up, and again too dumb to quit.

So yet again I gathered up strength and resources to bring the needed chemicals and tools, so after years of self research, a lot of money spent, sweat & tears I was able to accomplish what I set out to do. But success is a relative term, and Business Success and a Successful Spray On Chrome set up are not the same thing ... I am still struggling with making beautiful art that is well paid and costumers that want that beautiful art for less & less money.

So here is my advise, I have a friend in the business in India; here is my email address (nicamarvin2005@yahoo.com). Contact me and I will send you his contact information; purchase the required chemicals and tech support from him and save yourself the grief you are surely going to experience.

- Managua Nicaragua

|

|

adv.

Gold Touch [a finishing.com supporting advertiser], G.J. Nikolas [a finishing.com supporting advertiser] But in the general case we don't put readers into private contact with each other for a few reasons -- one of which is that this website is possible only through the generous support of our advertisers -- some of whom offer proprietary chemicals for spray chrome. Another is that it's unfair to other readers to follow along with great interest, only to be cut-off as discussions go private; it's like selling thriller novels with the last few pages ripped out :-) Regards,  Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted can be retained for immediate answers or long term project help Thanks Mr. Ted Mooney, I appreciate your comments. Yes it's true we need to support our supporters and I am the first to advise to purchase from our generous advertisers if you intend to be serious about this business, I am not sure how the customs in India are about importing from U.S.A. based companies, but I pay a hefty fee and Nicaragua is basically only about 2 hours from the USA. - Managua, Nicaragua March 29, 2017

Regards,  Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted can be retained for immediate answers or long term project help |

Q. Hi,

Team, I need top coat suggestions.

Seems yellow silver after spray.

Please solve this issue. How we can improve this?

- Delhi, India

April 8, 2017

![]() Best of luck cousin Sameer, and anyone is welcome to answer, but I'd suspect that we're pretty much done here :-)

Best of luck cousin Sameer, and anyone is welcome to answer, but I'd suspect that we're pretty much done here :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. The fact that you have made it to the Protective Top Coat means that you have done some progress, which is good, but you are not out of the woods yet.

Okay, so why does the spray silvering turn yellow after clear coating it?

Unlike metals such as aluminum or chrome, silver has an optical property called thin film interference that makes it appear pale gold or yellow when coated with any thin transparent film even distilled water. To counter-act this phenomenon, it is necessary to tint the first layer you apply to the silver with transparent Violet . While blue is the color opposite of yellow in terms of light, many blue colored tints tend to look green when they are very dilute. The red tones in a Violet tint counteract the greenish look of the blue to give a pure chrome like blue, not every tint will work and professionals use automotive UV resistant Violet tints or what are called candy concentrate.

Here are a few videos I made about the subject.

(Ed. update Oct. 2024: Apologies but these videos are no longer available)

I posted an answer to this question twice days ago, I was waiting for at least one to be posted, but it seems it got buried in the sea of questions that most likely spam this forum, it may get tiresome having to post the same answer multiple times, but I am sure I am not the only one so I will keep doing this.

To the question:

Unlike metals such as aluminum or chrome, silver has an optical property called "thin film interference" that makes it appear pale gold or yellow when coated with any thin transparent film even distilled water. To counter-act this phenomenon, it is necessary to tint the first layer of the top coat that you apply to the silver with a translucent violet tint. While blue is the color opposite of yellow in terms of light, many UV resistant blue tints tend to look green when they are very dilute. The red tones in a Violet tint counteract the greenish look of the blue to give a chrome-like appearance.

- Managua, Nicaragua

|

Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey Ted can be retained for immediate answers or long term project help |

A. I would like to add that I finally decided to use the Flame Treatment process instead of the wetting agent, I have tested it on small pieces and not only makes the highly hydrophobic surface of the articles very wettable and hydrophilic, it also provides outstanding adhesion of the Silver layer.

My concern was using a flame on a highly combustible article(plastic parts covered with petroleum base coating), but when properly applied the process is rather safe and the process is well documented and understood.

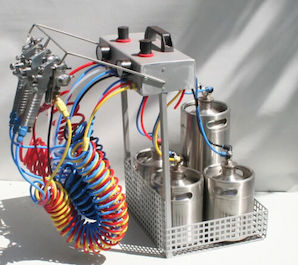

I am building a set up identical to this one on this video, Propane Torch kit for about $40 and a propane tank for larger parts.

Marvin Sevilla- Managua, Nicaragua

Q. Hi everyone

I need help with reducer I am using 15 gm of L(+), 150mg D(+), 7gm Formaldehyde Solution.

It's not working. Do I need to change the quantity or replace the chemical?

Thanks

Vishal Sharma

- Chandigarh, UT, India

June 14, 2017 2nd Request: August 15, 2017

Q. I need help to give the best reducer for chrome spray.

waleed akh- jordan amman

October 10, 2017

A. Hi Waleed. Much of this thread has been on that subject. Please try your best to phrase ongoing questions in terms of what has been said because simply starting over is the kiss of death to a thread :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hi All, I am from India. I've been seeing some youtube Videos of people doing spray-on Chrome. They are not showing the full process.

I've got a Paint shop here where I do custom paint jobs; I would like to do this spray-on chrome as well.

I have read all the threads

Here are the things which I have understood.

steps for Spray-on Chrome.

1. Prime the part which you are going to do.

2. Spray a black base coat.

3. Clear coat it using a 2k clear, in a paint booth. The parts should be dust free because whatever comes on your clear coat will been seen after doing the chrome.

4. Let it dry for a day.

5. Spray the wetting agent or Activator. Please help me how to make this wetting agent.

6. Wash it using DI water

7. Spray the silvering solution (from this thread I got some info on how to make the silvering solution thanks).

8. Spray the DI water again.

9. Anti oxidant to stabilise the silver. I don't know how to make it, please help me with this too.

10. Wash it with DI water again

11. Use air gun to kill the water drops.

12 Once dry, clear coat it with 2k clear

13.That's it, your done. Thank me later … please help with making the wetting agent and anti-oxidization chemical.

Cheers

Raif

Trust Hydro graphic's Printing - cochin, Kerala, India

July 24, 2018

Q. Hi all, great thread, love all the info!

I have recently started with the silvering process after doing about a year of research to find the chemicals etc.

Heres what I have:

1. 5%m/v silver nitrate solution

2. Stannous chloride dihydrate

3. DI water

4. 30% hydrochloric acid

My mixture:

1. 10grams of stannous chloride to 50ml acid, then I add it to 2liters of DI water.

My process:

1. On clean piece of glass, I rinse the glass with DI water, I spray the glass with my stannous chloride mixture, I rinse again with DI water, I then apply the silver nitrate.

My Problem

1. It doesn't seem to work at all.

2. I have read about the wetting agent but I'm confused with what it is.

3. I get only a light brown kind of color that deposits on the glass.

Is there anyone that can help me out here.

Please I'm really trying to do this and I love the effect of it, if only I can get it to work.

Regards,

Stephen Roberts

Grafikings Hydro Dipping - Nelspruit, Mpumalanga, South Africa

October 18, 2018

Q. Please help me with agent reducer. What amounts for 1L of mix? I know it has dextrose glucose but I don't know other chemicals and amounts. Please help me.

Pablo Michelle Lopez- mexico city, Mexico

October 30, 2018

Q. I'm from India, I need the formula for Silver, reducer and activator.

Here they sell it in small quantity in small container.

For activator A they pour it in 1 lt DI hot water

For silver they pour no 2 part first, and 3 and 4 simultaneously

Lastly pour container no.5 in 1 lt DI water

Can anyone tell me mixing formula for containers 1 to 5

I need the formula for manufacturing Activator, S and R for Hydrochrome; can anyone reveal the ingredients for each of them?

- Chennai, Tamil Nadu, India

January 23, 2019

Hi Saravanan. The seller CAN reveal the ingredients for each of them, but I doubt that they will. You may be able to find some of the ingredients from the seller's SDS and technical data sheets though.

Hi Saravanan. The seller CAN reveal the ingredients for each of them, but I doubt that they will. You may be able to find some of the ingredients from the seller's SDS and technical data sheets though.

If you wish to copy someone's formulation rather than buying the product, or licensing it, or developing your own, that's your choice ... and reverse engineering is widely considered legitimate when done properly. But might turn into crowd sourcing of industrial espionage is certainly not a legitimate way 🙂

Good luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I'm from India, I am workout diy spray silver plating but this chemical cad effect.so I need the Best formula for Silver plating solution(A), reducer solution(B) and activator.please guide me. I want Formula ratio 1000 ml. Please!

Mayuri ReddyJannat Enterprise - Hyderabad India

February 7, 2019

A. I would like to point out that when I first started with the so called Spray On Chrome process about 12 years ago, I had to adapt many old techniques and already proven processes to create my own DIY kit; I had to because any kits from proven manufacturers are worth many thousands of dollars and while the system I built was very sound, the weak link on it is the home brew chemicals and the Basecoat/Clear Coat.

I built my system around the LP Vinyl Record Silvering process, this process coats previously lacquered records with Silver using a two part chemicals mixed with a two part spraying gun.

For more info on the process you may want to check thread 45646 and thread 44444.

That will get you started with the Silvering process.

Let's say you master the Silvering process with your own home brew system (I never did), then the next step is to test Base Coat/Clear Coat system that will work with said system, I tried everything from lacquer to 2k Automotive coatings, I found the 2k system to be superior to non-catalyzed coatings, they give you super smooth glass like surface, but they are very hydrophobic, so stronger wetting agents are required (lacquer is very wettable in comparison).

In the end my home-brew chemicals did not produce reliable results always so I decided to purchase Mirror Silvering chemicals (much less expensive than spray on chrome chemicals) but my top coat was always turning the silvered process a yellowish tint, which is really not bad if you are going to make colored chrome parts (like blue, green, yellow, red) so I had to tint my clear coat with a Violet translucent pigment, while I wrote down the exact amount of tint per clear coat sometimes the ratio was off due to the manufacturer of the tint, now you can imagine how hard was to start over from that when the color did not match.

The entire Spray On Chrome process is unbelievably complex -- making your own silvering formula is just the tip of the iceberg -- you need to take into consideration coating compatibility, spray equipment settings (booth, compression, type of spray guns(cheap guns will give you cheap results), dirty compressed air will ruin your work).

- Managua, Nicaragua

A. It's very simple, Marvin -- why are you trying to make it sound complicated?

(Joking of course!)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hi everyone... I'm Lung; I tried chrome spray this month. But it always fails because I can't make the plastic surface I want to chrome to get wet. Any ideas for that? I'm trying to search the internet; it says you can't spray chrome without a wetting agent. Anyone know how to make a wetting agent? Do I have to use a special base coat? Thank you all.

Lung Xia- jakarta Indonesia

August 20, 2020

A. Hi Lung. Marvin Sevilla (whose post immediately proceeds yours now) is a highly accomplished chrome spray artist, and even he has struggled without success for 12 years trying to do without proprietary chemicals because of the difficulty of getting them in Nicaragua. He talks about the wetting agent on March 12, 2017 on this thread among other places.

Please give us your situation: are you using a proprietary system? If so, what do they say about the wetting issue? Or are you trying to develop a spray chrome system all by yourself? Thanks.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

![]() Thanks for replying uncle Ted. I'm just interested, and want to try it by following the instructions on the internet. But failed to make the surface wet

Thanks for replying uncle Ted. I'm just interested, and want to try it by following the instructions on the internet. But failed to make the surface wet

- Jakarta indonesia

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

Q. Good morning everyone. Please I'm needing an answer from an expert. How can I replace chloride tin by zinc chloride? Anyone here used this before? And what is the difference? Thank you.

Hakky victorInventor - North Africa

November 22, 2021

A. Hi Hakky. Marvin Sevilla said he's used it and it worked just as well; Geoff Smith says any chloride will reduce silver. But please put your question into context by describing yourself & your situation. Thanks!

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

November 2021

⇦ Tip: Readers want to learn from your situation;

so some readers skip abstract questions.

I am interested in knowing about Silver spraying systems & Silver spraying using Ammoniacal Silver nitrate. Can you share pdf on that.

Vippin Malakiemployee - Bengaluru, Karnataka, India

December 15, 2021

A. Hi Vippin. The general chemistry and the general procedures of that step is already explained several times on this thread. Please try to ask a specific question, and post the details of your own situation because the silver reduction step is probably the easiest step in the process of satisfactorily spraying "chrome-like paint". Proprietaries may not be essential if you're an excellent chemist and have time for experimentation, but they would make things much simpler for you :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I want to know about silver nitrate used in Hydrochrome® spray; what type of silver nitrate can I use for best results?

Please give me knowledge about it.

Employee - Odisha, India

April 14, 2022

A. Hi Jitendra. You can google for "SDS Hydrochrome®" to get the Safety Data Sheets for the silver nitrate and the reducer; these will give you the basics of the ingredients.

Good luck with it, you are certainly free to experiment yourself, but as Marvin Sevilla advises in detail on this page, even after years of intense development efforts his results fell short of what can be purchased right off the shelf. He has, however, been extremely generous in disclosing the details of his efforts, so take advantage of what you can learn from his postings, then have at it if you wish :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I've been looking into this spray chrome idea for about 2 years on and off. My problem is the amount of money that these companies ask for their chemicals. I understand there are proprietary formulas, however many use almost alike formulas. It is hard to justify the idea that if you can make the chemical mixtures yourself properly, it would cost roughly .20 cents a square foot, but buying it from a company is around $20 a square foot. Knowing these companies buy the chemicals to mix in bulk brings their cost down a lot more than what an average Joe would pay. So it costs these companies maybe .10 cents a square foot, but sell for $20 sq.ft. On top of that there are some that will not sell unless you purchase a system or kit. I find myself stuck. I would rather make myself, in order to save from the literal 20,000% mark up. How would one go about the savings, and find the basic formulas?

Pete Tetsohobbyist - Florida

May 18, 2022

A. Hi Pete. "The grass is always greener ..." Sorry, but I thoroughly doubt your 20,000% markup calculation :-)

All the information you need to get started in trying to make a viable spray chrome process is already on this page; the central "mirroring" step itself using silver nitrate and ammonia ⇦ on eBay or Amazon [affil link] or other reducer is pushing 200 years old.

The issue is, as Marvin tells us, that it's complicated to get good robust results. The base coat has to be right from many different perspectives: smooth enough but offering enough adhesion both to the base steel and subsequent layers, good at self-leveling, non-reactive with the subsequent layers, easy to activate, etc). The wetting step has to be done right. Then the activation step. The silvering process itself is, as mentioned, very old and established and recipes are on this page (as well as some warnings about ammoniated silver if you're tempted to use that) ... but Marvin warns that without that proper "activation" step before it, it just doesn't work like in the movies. Then you need a clear coat that is non-yellowing and doesn't hide the shine, but is tough enough to keep the silver from wearing off, and which doesn't affect the silver.

The starting info is all here, just as you can find the starting info for making the finest french pastries on line. But the chefs who bake them have little to fear from you or me, because it takes technique and broad knowledge from years of experience. Nor apparently do the sellers of proprietary chrome-like paint have much to fear from even the most dedicated individuals like Marvin.

Best of luck! One day it may be easier, but for right now it is quite difficult to develop your own robust chrome-look paint system. We would be very pleased to post whatever you learn from your experiments.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q, A, or Comment on THIS thread -or- Start a NEW Thread