Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Iridescence with patinas and metal restoration

INTRO:

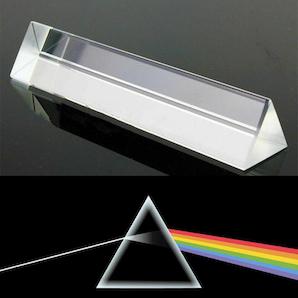

All of us have seen a rainbow split the white light of the sun into its spectrum of colors/wavelengths. Many of us have seen a triangular glass prism, do the same thing.

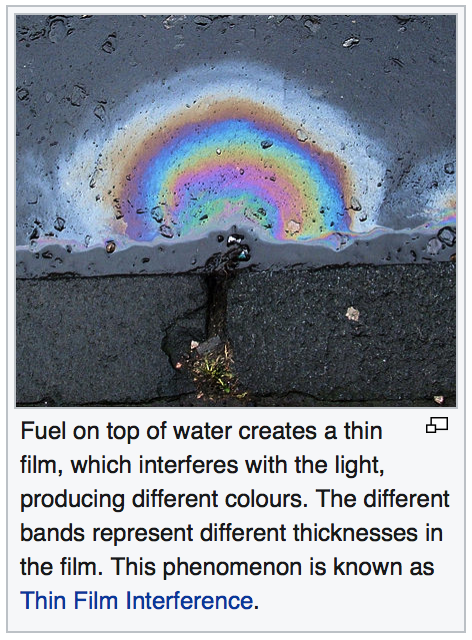

Iridescence is a phenomena which can make birds & animals or heat-tinted artwork beautiful ... or in other cases impart undesired colors like the image seen in a child's "toy quality" binoculars. A drop of motor oil on a mud puddle is the classic example or iridescence.

When a drop of oil lands on a puddle of water, gravity tries to flatten the oil as thin and level as possible, but surface tension fights back. The result is a layer of oil which is very thin and of slightly varying thickness.

attribution: John (Wiki ex-user Guinnog)

When light hits the puddle, part bounces off the top of the oil, and part passes through the translucent oil layer and bounces off the top of the water (actually the bottom of the oil). As this reflected light comes back to your eyes, the portion that traveled through the oil and bounced off the water has traveled slightly further, so the two portions are out of phase and interfere. Depending on the exact thickness of the oil film at that point, the red, orange, yellow, blue, indigo, or violet wavelengths may be amplified or attenuated.

Q. Hi,

I have the opposite problem: I'm looking for a way to increase iridescence, basically to get a 'soap bubble' kind of effect, in a clearcoat for a guitar.

There are, of course, several commercial paints and pigments (color shift, holoflakes, vinyl wraps, etc.) on the market, but what I'm looking for is iridescence within the clear coat itself, without adding anything else.

My research seems to suggest that lots of very thin layers of clearcoat would work, for the same reason the OP was getting thin-film interference rainbows.

Some old patents seem to suggest alternating solvent-based nitrocellulose with some sort of waterborne finish layer, to prevent the layers from melting into each other.

I'm wondering if it can be done purely with thinned polyurethane layers, or if there needs to be a wash coat of something between them. I presume each layer would need to be sanded and polished before the next one goes on?

Thanks in advance for your help!

- Chicago, Illinois

October 5, 2022

A. Hi AJ. I don't think it requires multiple layers because a single thin coat of oil can produce the effect. But I doubt that, with just a clearcoat, you'll obtain the richness & reliability of the commercial paints you mentioned which contain reflective beads and dusts.

Soap bubbles offer very dramatic coloration but they probably have the additional benefit of a prism effect on their backlighting, which won't be the case with a clearcoat on a guitar.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Thanks Ted! I think I have found a potential solution, using automotive tint film; there's a kind called 'Neo Chrome' that has the iridescence I'm looking for, and I might layer it over a chrome under-finish.

Thanks Ted! I think I have found a potential solution, using automotive tint film; there's a kind called 'Neo Chrome' that has the iridescence I'm looking for, and I might layer it over a chrome under-finish.

- Chicago, Illinois

⇩ Related postings, oldest first ⇩

by Bobbie Irwin

on AbeBooks

or eBay or

Amazon

(affil links)

Q. I've been trying to learn how to re-patinate old copper (c.1900) using liver of sulfur ⇦ this on eBay or Amazon [affil links] and ferric nitrate. I've used "Contemporary Patination" ⇦[this on target= "_blank" rel="sponsored,noopener,noreferrer">AbeBooks, or eBay, or Amazon affil links] (Young) and "The Colouring, Bronzing & Patination of Metals" [on eBay, Amazon, AbeBooks affil links] (Hughes) as references.

Now and then things progress exactly as I'd like, but I don't know whether these intermittent successes are more related to the actual alloy or something that I've done (or not). I'm trying to be as scrupulous as I can in preparing the surface using a commercially prepared cleaner that contains phosphoric acid.

My main problem is that the application of liver (either hot or cold) degenerates into a rather opaque coating of iridescent, metallic appearance. Typically, after the initial warm, coppery deposit, a bright gold forms followed by a magenta and then cyan coating.

For those not familiar with the original brown finish used on Roycroft copper, imagine the patina on a 100 yr-old hammered copper lamp...very heavy, almost black deposits in the recesses of the hammer marks with a warm, lighter brown revealed on their high points. I've been trying to build up most of the density I'd like with the liver to avoid having the entire effect become too red through the use of too much ferric.

In short, is this iridescence that I'm encountering typical of the process and, if so, how do I avoid having it happen?

Thanks,

Steve Pollock- Collingswood, New Jersey

2001

by Serge Berthier

on AbeBooks

or eBay or

Amazon

(affil links)

Q. I am similarly trying to restore the patina of a Stickley hammered copper bowl. I have ordered the books you mentioned and have had some success with online research. I am presently acquiring and testing all known techniques and chemicals. I have not tried ferric nitrate yet, but it is on the list of tests. I will test everything and then decide whether or not to go with Michael Adams' Aurora Studios repatination services. If you demand that it be done "right," his company is knowledgeable of the subtle differences between early and late finishes of Van Erp, Stickley and Roycroft metalwork. [Ed. note: this posting is from 2001; the internet changed a lot since, and we've learned a lot since; we can no longer post commercial suggestions ( huh? why?).

Regarding your iridescence, I have a similar problem with some of my blackening chemical reactions- such as a "bluing" like gun barrels. I can knock that down a bit if I abrade the surface with ultra fine scotch-brite. I am also going to try rottenstone ⇦ this on eBay or Amazon [affil links] and olive or boiled linseed oil ⇦ this on eBay or Amazon [affil links] on a felt covered block. Though I have not tried it, one other idea is that perhaps the final step of wax polish -- turpentine ⇦ this on eBay or Amazon [affil links] and bee's wax ⇦ this on eBay or Amazon [affil links] -- will reduce such colorations.

Good luck and keep posting on your progress or with any tips you have for my restoration.

J. McGowan- Huntington, New York

2001

![]() Hi Steve, J., and readers ...

Hi Steve, J., and readers ...

We have added a Intro on this page which may not solve your problem but will explain it so that you can better anticipate what changes might help.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q.

Hello Everyone,

Maybe someone can give advice...

I use clear gloss Lacquer to dip sterling silver to prevent tarnish. I have discovered that under bright florescent lighting there is a rainbow color that shows up when you hold it up to the light. I called the company and they said i thinned my Lacquer to much with thinner, so I mixed a new formula very thick but it doesn't seem to make a difference! Does anyone have advise?

Thanks,

- Brooklyn New York

July 30, 2021

A Book About Henri Matisse"

by MacLachlan & Hooper

on AbeBooks

or eBay or

Amazon

(affil links)

A. Hi Leo. I can tell you what is causing the problem, but have to leave it to you to solve it for your individual case.

When light hits a clear-coated surface, a portion of the light bounces off the top of the clearcoat and reflects back at you, a portion of the light passes through the clearcoat and bounces off the metal (some would say it actually bounces off the bottom of the clearcoat, but that's not an important distinction for practical purposes) before reflecting back to you. The portion of the light which passes through the clearcoat travels further by a small distance (a partial wavelength), so the two halves are out of sync and interfere, causing amplification of some wavelengths (colors) and attenuation of others. The more consistent the thickness, the less the iridescence. Multiple layers like a clearcoat followed by a light sanding followed by a wax might create a hodgepodge of reflection to limit the iridescence.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Thank you for responding.

I'm confused, however, why it's only showing up in fluorescent lighting and not in any other lighting. I tried many different mixtures -- thicker, thinner, etc -- nothing seems to help.

Thanks again.

Your help is much appreciated

metal repair - Brooklyn New York

A. Hi again, Leo.

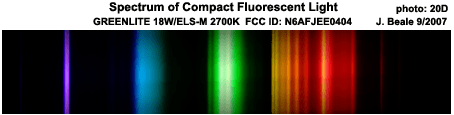

If the sun were a giant fluorescent bulb, this is what a rainbow would look like:

(Courtesy of http://www.bealecorner.org/best/measure/cf-spectrum/)

Fluorescent light is not "white" light like from the sun. It's not the full "rainbow of colors", the full solar 'spectrum'; rather it's just some pieces of the spectrum, some selective wavelengths. Look at the shiny side of a compact disc or DVD under fluorescent light and this is the kind of "rainbow" you'll see.

All I can say for your case is that the iridescent effect is apparently more obvious where you have this limited spectrum. Please try my idea of very lightly sanding your clearcoat, followed by waxing to fill in the 'divots', and see if the hodgepodge of different reflection and refraction angles helps mask the phenomenon.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Explanation given by Ted is correct. This happens when film thickness is comparable to wavelength of light. As the thickness increases, light rays undergoing multiple reflections lose their coherence and interference can not take place. Thus increasing the film thickness should solve the problem.

Those who are interested in the physics of this phenomenon may refer to our educational blog

https://asqphy.blogspot.com

Bangalore Plasmatek - Bangalore Karnataka India

![]() Thanks a lot I appreciate your help.

Thanks a lot I appreciate your help.

- Brooklyn NY

Q, A, or Comment on THIS thread -or- Start a NEW Thread