Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Need spring clips fabricated

Current Q & A's:

January 3, 2022Q. I would like to make a clip to hold fender flares on a car,

;

;

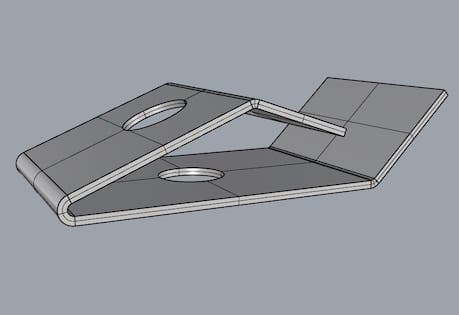

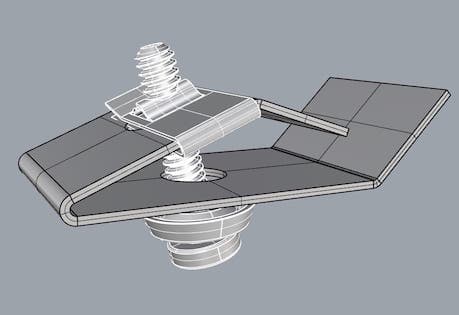

Q./RFQ. It needs to be bent with holes.

There will be 3 bends, 1/2" from each end at 45 degrees and one in the center at 130 degrees.

I then will add a speed nut and place in the assembly.

After assembly I will install the clamping screw. then tighten,

I do not want the steel clip to deflect, I want more like spring steel.

Should I make this out of 4130 and then post process or ... ??

Looking for ideas to get this laser cut and bent and then maybe heat treat in house?

Thanks in advance, Troy

- Tallahassee Florida

privately respond to this RFQ

Ed. note: As always, gentle readers: technical replies in public and commercial replies in private please (huh? why?)

A. Hi Troy. I'm not a metallurgist, so I can only offer a couple of quick comments, not a detailed analysis of your situation.

• Since you're looking for "more like spring steel", and 4130 isn't really a spring steel; you might want to use an actual spring steel, probably a 10XX.

• In the tough environment of an auto fender, neither your 4130 clip nor a plain steel speed nut will last long. You probably will want to consider "zinc-rich paint" like Dacromet or similar.

• Laser operations get cheaper, but making your clip from a standard width steel strip and simply punching the holes may be simpler, cheaper, and less involved that laser fabrication.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

January 2022

⇩ Related postings, oldest first ⇩

Alternate Coatings for QQ-N-290

2000Q. Good afternoon,

The Navy is currently seeking alternative coatings to replace the current electrodeposited nickel plating (per FED-QQN-290 (replaced by AMSQQN290) , Class 1-corrosion protection, Grade E-0.0006 inch thick) on a spring clip component. The nickel plating is not uniform over the entire component. The spring clip is made of AISI 1075 steel, and has a thickness of 0.0150 ± 0.0005 inch before plating. A fuze plug is inserted into an opening on this spring clip, leading to the eventual detonation of a warhead. The following properties of the spring clip must not be compromised, with the application of the proposed coating:

1. The proposed coating shall provide equal or greater corrosion resistance to the electrodeposited nickel (the current ADL requires a 24-hour salt fog test),

2. The electrical properties of the proposed coating should be similar to that of the nickel coating (the proposed coating shall exhibit a resistivity of approximately 10 - 20m Ohms, maximum) ,

3. The insertion value of the fuze plug should remain consistent with that provided by the nickel, i.e. the coating should not be too thick to hinder the insertion of the plug (the QQ-N-290 nickel at 0.0006-inch thickness was required to provide an insertion force of 5 - 35 pounds.)

4. The coating should be compatible with the soldering requirements (Type SN63 solder, at approximately 375 °F),

5. The coating should be compatible with the potting compound that it is to be encased within (Stycast 2651-40 & Catalyst 11 per MIL-I-16923).

If possible, please propose up to five alternate coatings (aside from electroless nickel which is already being assessed) which may be used in this situation, under these circumstances.

Marc S. PepiUS

A. EN is probably the best from the control standpoint, number of job shops available, and price that meet your criteria. Vapor deposited nickel is certainly worth looking into also.

James Watts- Navarre, Florida

A. We are currently providing Ni vapor deposition services for various types of small parts. These parts are solderable and will meet the corrosion criteria.

Mandar Sunthankar- Fort Collins, Colorado

Or see this related thread:

• Topic 53312 "Plating/finishing AISI 1095 spring steel"

Q, A, or Comment on THIS thread -or- Start a NEW Thread