Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Masking for Silver Plating

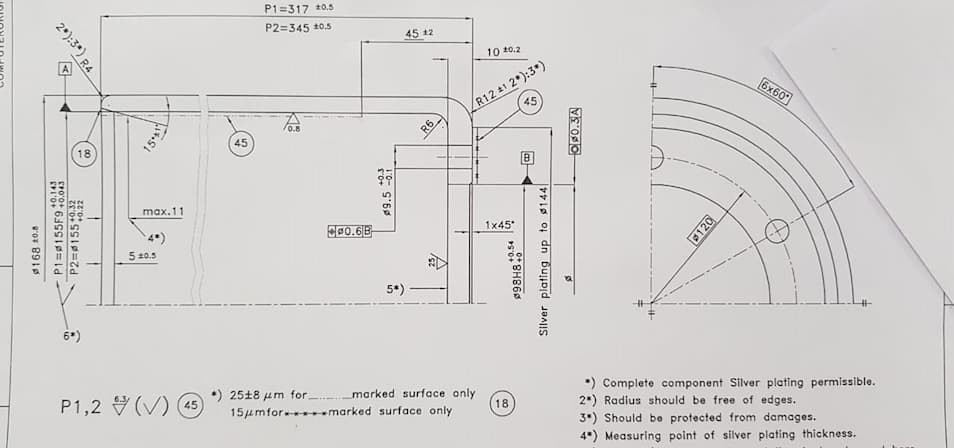

Q. Copper base material is fully coated with electroless nickel, then I have to do selective silver plating in the specified area of square blocks.

Need customized masking methods effective for selective silver plating.

VigneshMetallurgist - NPD - Chennai, India

March 5, 2025

Tip: This forum was established to build camaraderie among enthusiasts through sharing tips, opinions, pics & personality.

The curator & some readers who publicly share their info will be less likely to engage with those who don't.

A. Hi Vignesh,

This looks like it would be very easy to do either with die-cut platers tape or with photosensitive masking, except for those grooves which look like they will cause undercutting, trapped solutions, etc.

I think the first possible way would take two steps: first a liquid masking to fill the grooves and level them out with the rest of the surface, giving you a flat surface to work with, then adhesive masks with the squares cut out can be taped in place.

The second option would be photo masking; maybe the photoresist could fill those grooves so when UV light shines on everything but the squares, the rest is coated, but I don't have enough experience to know whether the resist in the grooves will cure in such a case, or if that would require pre-filling the grooves as well.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

⇩ Related postings, oldest first ⇩

Q. Hello,

I need to do silver plating on the inner surface of a hollow aluminum cylinder. The place where things get interesting is, only a certain area inside the hollowness needs plating , rest of the inside area needs to be masked. So, my question is twofold ---

1. What would be a good masking method? I have used masking lacquers in the past but I would like to know if there is a better alternate option since the masking has to applied inside the cylinder.

2. Is there any literature/documentation that talks specifically about fixtures for electroplating work? What I can do is, cover the area where plating is required with the fixture and then just dip the whole component in a container of lacquer. This way, I can mask the area where plating is not required. Once the lacquer dries up, I would remove the fixture and move ahead with the actual plating work. I am more interested in the material from which the fixture should be made. Like, silicone sleeves or metal fixtures or something else.

Any help is highly appreciated.

Thank You,

- Baroda, India

December 19, 2020

A. Hi Shreyas. I'm not totally sure that I am understanding you since, to me, 'fixtures' means 'plating racks', and plating racks usually try not to shade anything, but rather to minimize any 'rack marks'.

However, from continuous plating machines for integrated circuit lead frames (less common now in this age of surface mount components) I am familiar with the idea of rubber/vinyl 'moveable masks' which would limit precious metal plating to designated areas.

So, yes, you could build some sort of fixture that you mount the hollow cylinder on which excludes the lacquer, leaving an area lacquer-free so it can accept plating. You haven't told us the size of these aluminum cylinders yet so it is hard to visualize what the fixture would be built from and what it would look like though.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello Ted,

Thanks for your prompt reply.

By 'fixtures', I was actually referring to a mask. This mask will be put in the area where plating is not required. Sorry for confusion.

As you mentioned rubber/vinyl 'moveable masks'. Would you be knowing where can I find some literature/documentation for it? Like how are they designed/manufactured, etc. ?

Please see the drawing and actual pictures of the cylinder in the attachment link. All dimensions are in millimeter. I have the 345 mm long cylinder.

You are right, Yes, I would also have to design a plating rack on which the cylinder would be mounted for plating work.Any ideas about that also would be of great help.

Thanks a lot.

- Baroda India

sometimes on

AbeBooks or Amazon

(affil links)

free pdf is currently available from academia.edu

A. Hi. Sorry, I'm not aware of any literature specifically on masking methods and materials, but the article "Continuous Strip Plating of Electronic Components" by John Donaldson (can be purchased from sciencedirect.com) in the 1998 edition of the Metal Finishing Guidebook talks about and offers general sketches of masking techniques for continuous strip plating.

The Electroplating Engineering Handbook ⇦ this on eBay, AbeBooks, or Amazon [affil links] and recent issues of the Metal Finishing Guidebook each have chapters on racking for electroplating.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Hi Ted,

Hi Ted,

Thanks for the digital version of Metal Finishing Guidebook and the tip about sciencedirect.com

I appreciate all your help Sir.

- Baroda India

A. Hi Shreyas,

1. Any specialized rack, fixture, or masking-aid will make sense only if you have an expectation for a large amount of such parts.

2. Inserting a temporary rubber/silicone mask on the plating area and dipping the whole assembly into the lacquer may not work. Reason - drying lacquer will form a layer covering part AND temporary mask, so you may have troubles to cut the lacquer layer and have a well-defined plating line (lacquer edge). So, plating solution may penetrate under a lifted lacquer's edge.

3. Depends on your Silver plating solution, some plating WAX (melted wax) may work as a masking material instead of lacquer.

Good luck.

- Winnipeg, Canada

A. Hello Shreyas!

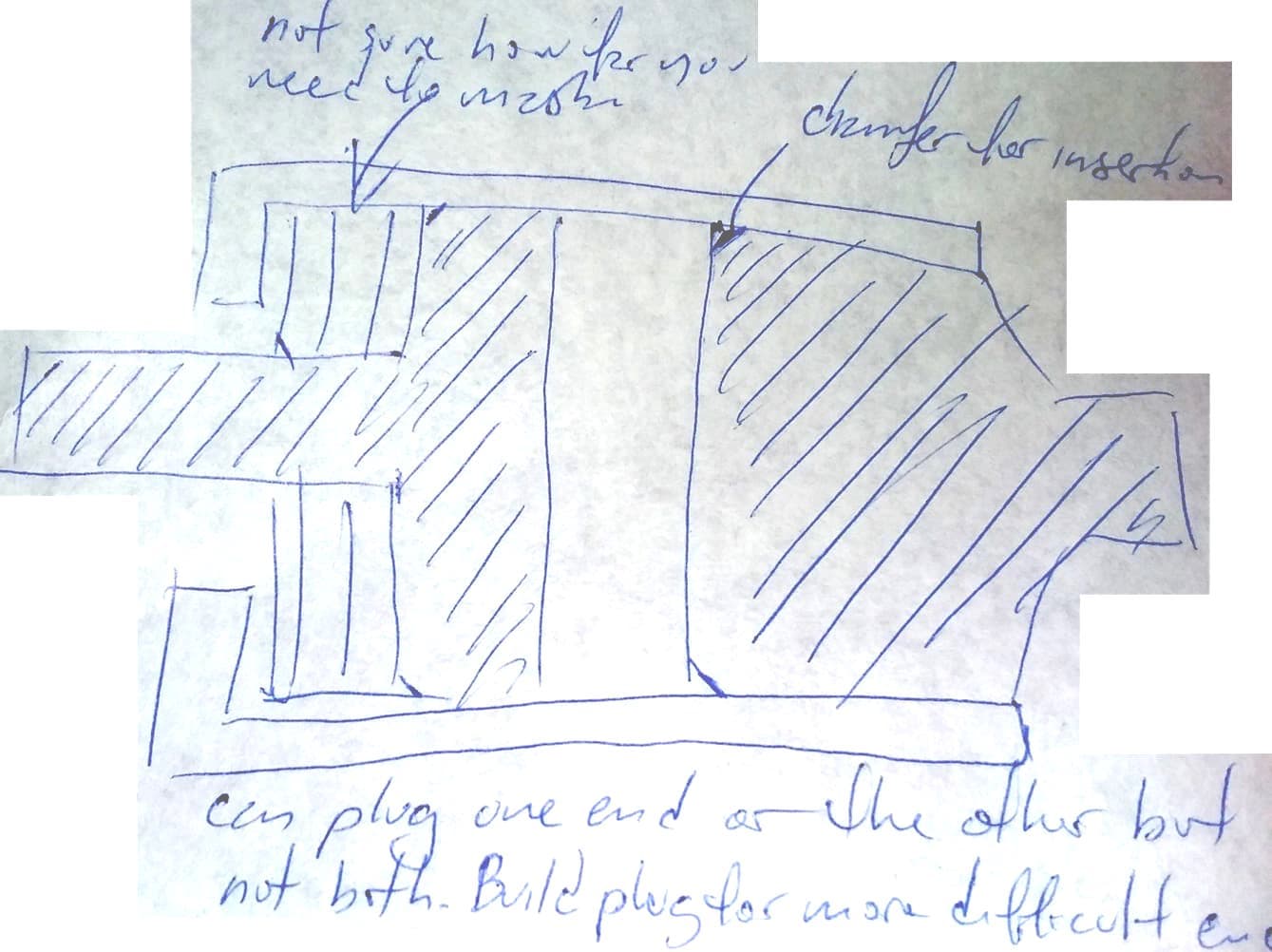

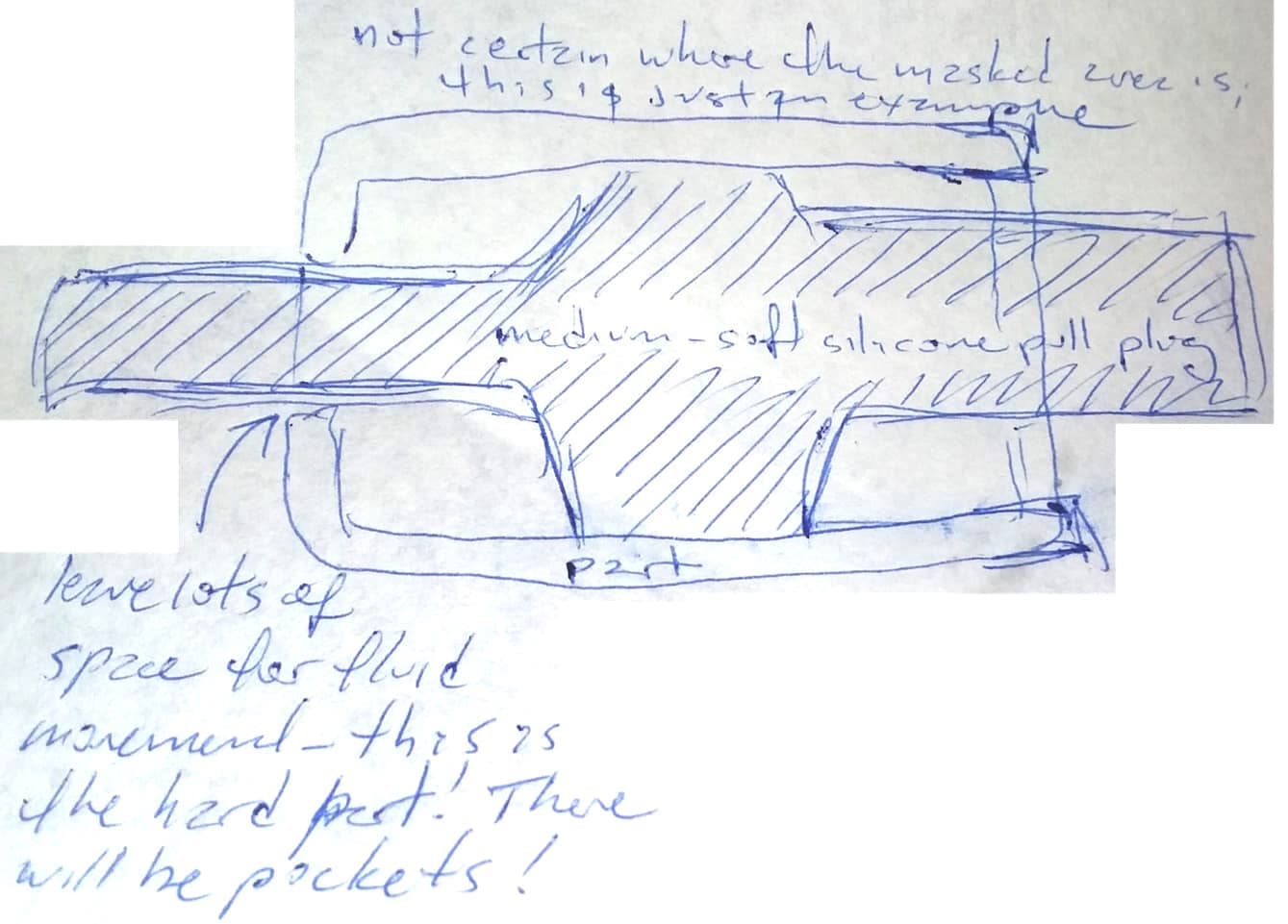

I'm not quite clear on where exactly the intended plating is within your part, but your problem may require an approach that uses more than one type of masking, because of the risk of air pockets and restriction of plating solution circulation inside a processed piece. If it's intended to plate on one end, it's easier. If you need a band of plating within the bore, but masked at the ends, it's harder.

Look at my response on the masking for keyways thread for an idea of DIY plugs that you can try, as a background for the technique.

If you are PREVENTING plating in an internal band, you can make a single pull plug with tails. Just beware of air pocketing.

If you are actually only plating in a band, you will probably have to combine methods, including adhesives, and cured gel/lacquer types, and may find use for pull plugs.

Unfortunately masking for the lacquer application itself doesn't work so great, especially in bores where you can't use a razor, because when you go to peel off the maskant, instead of a clean edge, the lacquer can lift up or crack, or if its still soft, can leave gooey contamination.

A combination of green powdercoat tape, applied carefully and rubbed down with a dull wooden dowel for full adhesion, to hold crisp edges at the margins, plus maskant lacquer over and beyond it to cover the rest of the surface, works well.

I've passed along a couple sketches for pull plug ideas in case that would help give you an idea for cutting time off masking.

Rachel Mackintosh

lab rat - Greenfield, Vermont

Q. Hello Leon and Rachel,

Thanks a lot for your reply.

Leon,

1. Yes, if I am successful at plating the sample parts as per customer's drawing, then they have hundreds of such cylinders which would require specialized rack, fixture and masking-aid.

2. I see your point of how putting a silicone mask and dipping the whole assembly in lacquer is a bad idea. Thanks for your suggestion.

3. Do you know any US company that makes and sells electroplating wax ?

Rachel,

Thanks for taking extra pain to make the sketches. Yes, it definitely gives me good idea of using plugs.I read your response on the "masking for keyways thread" and I understand that you might not be in favor of custom plug professionally made. But still, can you suggest any US company that makes silicone pull plugs ? I see stuff on Amazon but I would require some customized plugs from a manufacturer.

- Baroda India

----

Ed. note: Readers are encouraged to name a source which might help Shreymas, but no testimonials please (why?)

A. Argon Masking and EPSI in the US, and Vicone in Canada are reputable. I have done business with all 3. Just be ready for a hefty fee for the initial plug mold development for custom work, and a minimum order once your design is proved out.

Rachel Mackintosh

lab rat - Greenfield, Vermont

![]() Thanks a lot Rachel. I really appreciate your help a lot.

Thanks a lot Rachel. I really appreciate your help a lot.

- Baroda India

January 19, 2021

A. My pleasure! I'd still recommend starting with a couple of trials making your own based on what you feel will be the best approach to your project, if only for proof-of-applicability; coming close to your goal with imperfect home-made plugs, or failing miserably but catching it before you commit to a moldmaking fee, gives you a much better starting point and will almost certainly save you a few bucks in the end when and if you bring in a plug fabrication shop.

Best of luck!

Rachel Mackintosh

lab rat - Greenfield, Vermont

Q, A, or Comment on THIS thread -or- Start a NEW Thread