Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Problems Chrome Plating ABS Plastic

Quickstart (no readers left behind):

Real chrome plating of plastic is done for such applications as automobile grills and shower heads. It is an expensive, complex process involving sequential immersion into 15 to 20 different process solutions. Readers may wish to start with our "Introduction to Chrome Plating" or our "How high quality plating on plastics is done".

This thread addresses some of the problems encountered, but some such issues are so common that they have earned their own threads, which you may wish to review as well --

Thread 30406 "Pitting and roughness problem on Chrome-plated ABS"

Thread 48430 "Worming in chrome plated ABS"

Thread 55390 "Appearance of cracks in chrome plated ABS plastic"

... or search the site for many other threads about plating on plastic.

Q. Hi I'm from South India I'm facing problems like uneven plating in copper, nickel chrome plating on ABS plastics. After copper plating the ABS parts show uneven plating that is not bright in C surface area, and low thickness. Increased current density also but not effective.

Kindly suggest me a solution.

DevAssistant manager plating - India

April 1, 2025

Tip: This forum was established to build camaraderie among enthusiasts through sharing tips, opinions, pics & personality.

The curator & some readers who publicly share their info will be less likely to engage with those who don't.

⇩ Related postings, oldest first ⇩

Q. Can anyone help me? I want to plating ABS. But not all of the surface. That is partial.

by American Society for Electroplated Plastics

on AbeBooks

or eBay or

Amazon

(affil links)

plastics - Izmir, Turkey

2002

A. This is widely done, Murat. In fact, millions of automobile grilles are partially plated. But to prevent a sloppy demarcation line caused by overgrowth and nodules, the "breaks" should not be in a flat area, and preferably should be in a recess.

"Standards & Guidelines for Electroplated Plastics" ⇨

has a whole chapter on selective plating considerations.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi,

Is there a way of decorative chrome (or chrome-like in appearance) a non metallic material such as ABS? I have a home bathroom project with an exposed piece of black ABS pipe (actually it's an elbow) that needs a chrome appearance. Possible? Obviously an electroless process?

Steve GeldmanHomeowner - Westlake Village, California, USA

2003

A. All sorts of drains, shower heads, etc. are chrome plated plastic, but I don't see chrome-plated ABS piping at home improvement stores or on the internet.

You cannot do actual chrome plating yourself, and it would probably cost well over $100 to have a shop chrome plate one for you. I'd either go to the hardware store for some shiny metallic paint, or look for some chromed vinyl adhesive sheet.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ed. update: Vinyl car wrap has now become popular and well developed to where it even includes microscopic holes so it doesn't get bubbles or creases.

A. Hi,

I am also trying to find 1 1/4 and 1 1/2 inch chrome plated plastic (PVC) pipe for plumbing in exposed pipes in a bathroom, if I find anything I will get back.

Regards

Tony

- Mytchett, Camberley, Surrey, England, UK

2006

Q. We are facing peel off problem & crack mark problem in our plastic part (material - ABS) which was chrome plated. May we know what is the reason behind that?

V.Veerasubramany- Chennai, Tamilnadu & India

2007

A. Thank you for visiting finishing.com, Veerasubramany, but chrome plating of plastic is a complicated process, with a half-dozen possible reasons for a given failure. Sorry, but we'll probably need more information.

Is the chrome peeling, or the nickel, or the copper, or the electroless nickel? Likewise what is cracking? What preplate cycle are you running? Have these parts been successfully plated in the past? Is the problem on every part or on one part in ten thousand? Thank you!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

Q. Sorry, Forgive me. Now our problem is, we have a plastic part (ABS material) which was chrome plated. The plating procedure is first copper, then nickel & then finally chromium. Now we are facing some issues like peel off, crack mark (some line marks was observed) and bubbles in the surface area of the part.

May we know what the reason behind that is? Waiting for your reply. Thanks in advance.

V.Veerasubramany [returning]- Chennai, Tamilnadu & India

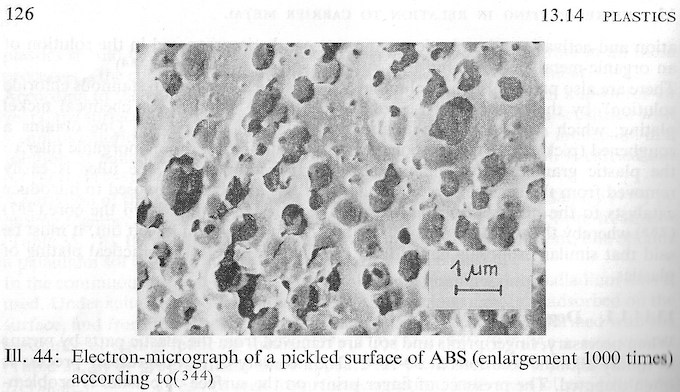

A. If all of the layers are peeling off, it sounds like your etching process is not working properly and the plating is not getting a good tooth or key on the plastic. This needs to be solved before looking at other issues like cracking.

The beauty of ABS is that it can be etched to a sponge-like surface, where the holes fill with metal, really locking the plastic and the metal together. Courtesy of "Chemical (Electroless) Nickel Plating" by G.G. Gawrilov ⇦ this on

eBay or

AbeBooks or

Amazon [affil links], here's a nice micrograph explaining it -- the dark areas are sponge-like hollows.

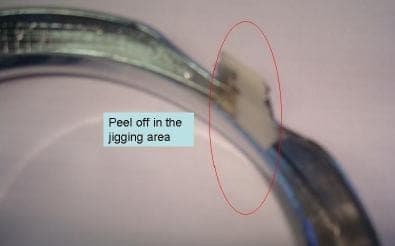

But if peeling occurs only in the jigging area, which is a low current density area, perhaps you're getting no copper coverage there (which might result in passivation before the parts get to nickel plating). What you see on the underside of the peels and on the substrate underneath the peeling can help tell you what step peeling occurs at.

Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have a problem that I have been dealing with one of my suppliers provides me with a small plastic component made from ABS material this component is then plated with chrome. Now the issue's I'm have are as follows:

1. ABS component after chrome plating becomes very brittle almost like glass. At the fracture areas it appears to be very shiny.

2. After plating on the same sample there is what appears to be residue on the non plated area that is brown in colour.

I guess my question is what causes the ABS material to become brittle in the plating process and is the brown spots noticed on the non plated area related to the brittle condition?

Cory

automotive - Ontario, Canada

March 10, 2009

A. Hi Cory,

When plating ABS or ABS blends the molding is a vitally important step in the process and it is one that is often overlooked by the plater.

The molded part may be stressed before it even goes to the plating shop due to a number of possible reasons, melt temp, injection times/pressure mold temp, etc.

You should first check the molding for stress by immersion a part in conc. acetic acid

⇦ this on

eBay

or

Amazon [affil links] for 45 seconds and then rinsing and drying. If the surface shows white marks/lines then that is an indication of a stressed area.

If there are no white marks you need to ask your plater to check the stress numbers of his Ni deposits.

Cheers,

- Hong Kong

Q. We supply a chrome plated ABS hub cover. From time to time we get complaints about the surface wrinkling for lack of a better word. They can be robust wrinkles and or very soft almost skin type wrinkle. Have you seen this before? Our belief is the robust occurrences are when rapid temperature changes take place in the field. High Heat to cold - cold to high heat. The application could be confronted with temperatures past 230 °F due to brake and or wheel bearing problems - it appears the ABS is softening and taking the plated surface with it understandably as they have different heat COE - thank you

John Bella- Cookeville, Tennessee

October 24, 2012

A. Are you positive about those 230 °F? That's water boiling point. I'd bet that the bearing grease must have got fire. Very unlikely any plated plastic will survive that without damage, more so ABS.

Guillermo MarrufoMonterrey, NL, Mexico

PC ABS Plating cracks

Q. My situation:

We are a plating part supplier to automotive industry.

Currently we are facing plating crack issue.

Part cracks when vehicle is parked in stock yard (it's a delayed failure).

The part width is 10 mm and thickness is 2.2 mm.

Its a instrument panel garnish.

Length is approx. 900 mm.

The crack is generated on the copper to chrome layers.

The crack are similar in size (vertical).

Plating thicknesses checked and are within tolerance.

Can anybody help?

avail from eBay, AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

"Plating of Plastics with Metals" by John McDermott (1974)

avail from AbeBooks, or Amazon

avail from eBay, AbeBooks, or Amazon

avail from AbeBooks, or Amazon (rarely)

"How to Electroplate Non-Metallics" by Warner Electric Co. (1967)

[more appropriate for hobbyists than for industrialists]

avail from eBay, AbeBooks, or Amazon

avail (rarely) from eBay, AbeBooks, or Amazon

(as an Amazon Associate & eBay Partner, we earn from qualifying purchases)

- Delhi, India

July 11, 2018

A. Hi Manu,

My first guess would be that even if the nickel plating thickness is not excessive, its internal stress is. Please search the site for "nickel stress"

Nickel-chrome plating on ABS is an involved subject and we have a thread "Appearance of cracks in chrome plated ABS plastic" which you might like to review.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Wrinkle marks visible in copper plating

Q. Our company major issues now wrinkle marks visible in copper tank ... we are trying our best analysis but we can't solve this issue ... please any suggestions. Why come wrinkle marks; how to solve this issue ... it's come in copper on electroless nickel.

Selva kumar- Chennai Tamilnadu, India

July 30, 2020

A. Hello Selva,

You don't mention anything about your actual process steps so it's hard for me to give you suggestions. Give us your process flow please.

- Winston Salem, North Carolina USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread