-----

Steam Sealing of Anodized Aluminum

1998

RFQ: Looking for an Aluminum Hard Coat Anodizer with Steam Sealing capability, in either a R&D or production mode.

Gary EscherEd. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

1998

adv.

Luke Engineering would be happy to work with you on an R&D basis. We have plenty of hardcoating capacity and can set up for steam sealing. We currently have no commercial applications for this process.

Luke Engineering & Mfg. Co. Inc.

Wadsworth, Ohio

1998

RFQ: Aluminum Hard Anodization Steam Sealing Capability

Looking for a supplier of Aluminum Anodization Steam sealing equipment or an end-user of this equipment in the USA

Gary Escher [returning]Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Hi Gary. I'm not aware of such equipment, although it sounds like a good idea. All that I have ever seen is the anodizer emptying his boiling water seal tank, tarping it, and letting live steam into the tarped tank. The approach is a bit clumsy for the new millennium, so if there is a better approach, let me know, folks.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

1998

1998

adv.

H&H Equipment may be able to help you.

See our ad on this site under suppliers.

Multiple threads merged: please forgive chronology errors and repetition 🙂

2000

Q. I am interested in steam sealing anodized aluminum, but can find very limited information on the subject, i.e., times, pressure, equipment needed. Any help would be greatly appreciated.

Thank you

Marc Green

anodizer - Boise, Idaho

A. Hi Marc. The only steam sealing I saw was done in a regular open topped tank which had been fitted with steam nozzles and had then been tarped over to keep most of the steam inside. It was sloppy and retro even back then, and I didn't see any particular advantage over a boiling hot D.I. water seal except saving the cost of the deionizing equipment.

So, the pressure was ambient, the time was the same as hot water sealing (about equal to anodizing time ideally, but certainly no less than half the anodizing time); there are a number of sources for steam nozzles.

There must be better modes of steam sealing that I'm just not acquainted with. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

2000

Q. We are looking to build a line dedicated automated anodising line to do a particular job. Currently we are running the part through our jobbing line where we use a cold seal system.We are researching steam sealing as an option because it has the ability to give us a dry part off the line as well as being 1 process tank less. Are there any opinions on steam sealing out there?

Colin Christianjob shopper - Australia

August 10, 2011

August 10, 2011

A. Hi, Colin.

I think that the advantage of steam sealing is no chance for contamination. For example, there is no chance of accidentally getting a bit of sodium dichromate on the parts and flunking RoHS, or contaminating a yellow part with a trace of red dye because there is no liquid in the seal tank.

I haven't seen much actual steam sealing, though. The only time I've seen it, it was quite awkward as the sealing tank was manually tarped to contain the steam. Hopefully other readers will be more experienced in it. I've seen a number of hot water seal tanks, but they lack the anti-contamination benefit I cited, although deionizing can remove much of that risk.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. We used to perform steam sealing for a Japanese semi-conductor customer several years ago. Personally, I found it to be a pain in the keyster. To do it properly, it required a rather large autoclave (our customer required us to do it at 50-60 psi) to which we had to move parts (sometimes large) in and out of, the internal temp of the autoclave reached over 250 °F, which made the parts very difficult to handle when removing (and also heated up that area of the shop A LOT!!!).

The method that Ted mentioned, is rather ineffective, in my opinion. Of course, we had to buy a boiler, and plumb everything to the autoclave. End result was that through multiple testing parameters (corrosion tests, EIS, voltage breakdown, etc.), we saw very little advantage in this process as far as coating properties go. And to make matters worse, the seal smut was horrendous. We ended up convincing our customer that we could duplicate the same coating properties through alternative methods of sealing, and dismantled the system.

Honestly, I fail to see why you are even considering this, as if one were to use a hot DI seal (200-212 °F) your drying time is very minimal.

Marc Green

anodizer - Boise, Idaho

August 11, 2011

Characterization of Anodizing Steam Sealing - Anybody?

Q. Has anybody characterized steam sealing? I have searched through as much of the literature as I can find, including this site and heard from others in and out of industry and nobody seems to say much about it other than it's a viable sealing method, always lumped in with boiling water sealing. I always see it talked about as an expensive option and one that is rarely undertaken in the USA but it seems superior to boiling DI water sealing. I can find absolutely nothing on temperatures (except hotter = seals faster), the chemistry behind it, if it is commonly done under pressure or at room temperature. Do companies use boilers to generate their steam? How do they generate their steam? How do they prevent smut from forming or at least minimize it? Could you steam seal in a commercial autoclave?

If you are trying to steam seal, can you simply place wet parts into a cold autoclave and then turn it on, such that it still dry parts out before steaming them? Or would that cause the parts to dry out first?

What prevents parts from drying out when being steam sealed and is it bad for the parts to dry out?

What prevents acid from leeching out of the pores of the parts when steam sealing and disrupting the finish of the parts? Nothing is really rinsing the parts off while they are being sealed.

What about steam quality?

Steam quality measures how much liquid water is traveling with the steam vapor. It is expressed as a weight percentage. For example, if 100 pounds flows through the steam

line, and 5 pounds of it is liquid water, then 95 pounds is steam vapor. It is 95% steam quality.

Steam Quality Comparison

(Vapor) (Liquid) (Percent by weight) (Percent by volume)

100 0% 100 100.000

97 3% 97 99.997

95 5% 95 99.995

90 10% 90 99.989

80 20% 80 99.975

50 50% 50 99.901

Does it even matter what steam quality one hits?

Sorry for all of the questions but I cannot find any literature that speaks to the specifics of steam sealing anywhere.

Employee - Austin, Texas USA

February 11, 2015

Treatment &

Finishing of

Aluminium and

Its Alloys"

by Wernick, Pinner

& Sheasby

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi Bobby. Wernick, Pinner & Sheasby has about 3 pages on steam sealing with about a half dozen references.

The coverage doesn't seem very conclusive, but it does seem to me that the authors believe steam sealing is fine, but they don't give much credit to high pressure/high temperature approaches, and don't feel that corrosion testing actually demonstrates the superiority of steam sealing over other methods. Hardly a tight characterization, but at least a tiny piece of the puzzle :-)

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Yes we used a boiler to generate the steam, and we used a large autoclave. There are very large commercial autoclaves on the market, all SS, if you're prepared to drop a large amount of money.

We never found a way to minimize the seal smut, it was absolutely horrible, and labor intensive to remove. Since we've stopped this process (thank God), there have been additives available on the market for DI water sealing that may be effective in reducing smut in steam sealing. I don't know if that would work or not, and it also sounds like maintaining a proper concentration of additive in the boiler tank would be a challenge as well.

Our process was to pre warm up the autoclave to operating temperature (this was a lengthy process), evacuate the steam from the autoclave, and then place the parts in, and then re pressurize (also a bit of a lengthy process, but nowhere near as long as when starting cold) Once the desired pressure inside the autoclave was reached, that's when we started our timer.

I never noticed any issues relating to acid being leached out of the anodic pores.

Steam quality was a parameter we never checked, so I'm no help there.

I'm thankful every day that we discontinued this process years ago. I found it labor intensive, and dangerous...all while adding little, if any benefit, to the end product.

Steam sealing is primarily a Japanese deal. They have probably perfected it into a somewhat viable process. Someone (consultant) in Japan would probably be the best place to start for getting really information and processing techniques.

Marc Green

anodizer - Boise, Idaho

Q. The only example I have seen in the literature is a brief blurb about it in the Metal Finishing 2011/2012 Surface Finishing Guidebook that claims it has "a reported reaction rate increase of two to four times that of DI immersion".

It references:

L. Hao and B. Cheng, "Sealing Processes of Anodic Coatings --Past, Present, and Future", Metal Finishing, Elsevier Inc., December 2000, pp. 8-18 as the source for this claim.

So digging deeper, when you read L. Hao and B. Cheng's paper, they claim that "the diffusion rate of a substance increases by about 30% for every 10 °C increase. It was found that there was more weight gain on the anodized panels with steam sealing at 115 °C than with boiling water sealing." which it attributes to:

Brace, A.W. and P.G. Sheasby, "The Technology of Anodizing Aluminum," 2nd Ed., Chapter 16, Technicopy Limited, England; 1979

How "two to four times that of DI immersion" is extrapolated from 30% for every 10 °C increase is beyond me though. If DI immersion happens at 100 °C and atmospheric PSI and most autoclave steam is only getting to 130 °C at about 25 PSI and 145 °C at 45 PSI and 170 °C at 100 PSI. To achieve 4 times the sealing rate, you would have to be steam sealing at something north of 50 PSI, assuming this quoted 30% number is a linear increase (meaning 20 PSI above ambient equals 60% faster sealing).

I see reports of steam sealing being performed at 75 °C, so it's certainly possible and of course one could achieve greater than 200+ PSI steam chambers if one wanted but at some point one has to imagine the time to load and unload and bring things up to temperature to become far greater than the value of slightly slower sealing processes.

L. Hao and B. Cheng's paper goes on to further state that "the anodic coatings resulting from steam sealing are even softer than those from hot water sealing because of high conversion efficiency from oxide to boehmite. Corrosion and scaling problems in a steam generator may be encountered by operating a steam-sealing process."

and

"Hot water and steam-sealing processes are environmentally benign. Unfortunately, they substantially reduce the abrasion resistance of anodic coatings, are not recommended for dyed parts, and sometimes lead to unsatisfactory appearance."

Plenty of people successfully operate with hot water sealing processes for dyed parts.

It doesn't really characterize the steam process at all and mainly asserts that it's not as good due to the reduced (by how much?) abrasion resistance. But nobody seems to actually provide data to support how much poorer in abrasion resistance you are actually likely to see in practice.

Trying to better characterize this, I referenced Boeing Process Specification: BAC 5884; April 21, 1995, which showed that using the Taber result, hot water sealing actually wasn't that much worse than nickel acetate sealing for abrasion resistance. It also shows that no sealing at all is the best for abrasion resistance, with dichromates being the next best. It's no wonder that they persisted for so long (and continue to do so).

Sealing Process Taber Result, mg/l0,000 cycles

50 µm Type III coatings on 6061-T6 aluminum

Without sealing 8.4 mg

Hot water sealing, 100 °C 19.7 mg

Nickel acetate sealing, 90 °C 15 mg

Sodium dichromate sealing, 95°C 9.8 mg

Sodium silicate sealing, 85 °C 9.2 mg

Nickel fluoride sealing, 30 °C 11.5 mg

Assuming steam sealing is on par with hot water sealing, it's actually not that bad of a sealing process from an abrasion resistance perspective.

I guess I was hoping to see more examples of it being used and better characterized. Autoclaves are not that expensive overall if you are already building a tank (obviously at some point, tank size starts to impact things) and I have seen references of steam sealing being done at atmospheric pressure in just a draped chamber so pressure is not necessary to achieve a quality seal.

Nobody seems to post much about it though.

Marc, you stated that you "never found a way to minimize the seal smut, it was absolutely horrible, and labor intensive to remove."

I assume your parts were varied in geometry and required manual wiping off to remove the seal smut? With nickel sealing (or boiling water?) you do not see the same seal smut? Nothing was able to remove the seal smut? Even multiple steam and rinse cycles? See this thread for an example: letter 41975

Notably, when we steam seal test parts that we receive from other vendors, we generally see this type of smut on the surface of parts too. It's fairly easy to remove but labor intensive to actually do so.

Why did you consider the process dangerous? Because of the boiling, pressurized water? What PSI did you seal at? Is a tank of 212 °F boiling water also not potentially dangerous?

Just curious, trying to learn as much about this and decide if our bench testing is likely to scale or not and if it is worth the effort and investment to do so. Thank you for your time and expertise.

Employee - Austin, Texas USA

A. Bobby,

Yes, the parts were of varied geometries. The smut for us simply did not wipe off with a cloth, it had to be scrubbed off with Scotchbrite pads. This may be due to the fact that we were sealing for an extended time (2 hours).

All of our work is now sealed in boiling DI water. We cannot use Ni acetate due to the industry that we do work for (we are not a commercial job shop). We have an non metallic additive that we use in our seal tanks that inhibits smut formation.

As to the dangers. Our boiler was outside of the plant, and supplied the steam to the autoclave located inside the plant. The pressure spec was 55-60 psi inside the chamber..however the lines and boiler were pressurized much higher in order to maintain the 55-60 psi inside the chamber. We routinely operated at temps around 285 °F. There are inherent dangers associated with working around pressurized steam that just flat out made me nervous. Did we ever have an accident? No, we did not, thankfully. However minor burns did occur while placing and removing parts inside the autoclave. It was not a production friendly process for us, as there was downtime in letting the parts cool a bit before removing them from the chamber. Admittedly, our autoclave was really not designed for what we were doing with it, and could have been done better...however, it would have required a very substantial investment, which wasn't justifiable for the amount of work that we had that required steam sealing.

Compared to the DI water sealing that we currently employ...I often tell new line operators that our boiling DI tanks are the most dangerous tanks we have on the line. All of our anodizing chemistries are obviously diluted, and if an exposure happens, as long as proper first aid treatment is immediately preformed, the end result is rather minimal. However, if one is splashed with boiling water, you simply cannot get treatment fast enough to prevent the blistering and pain that will obviously occur.

In the end, we were able to prove to our customer through various testing, that steam sealing offered no benefit over DI water sealing, so the customer agreed to change their spec to allow DI water sealing.

Marc Green

anodizer - Boise, Idaho

A. Bobby, I should have also clarified that abrasion resistance was not an end goal with our use of steam sealing. It was corrosion/plasma resistance for parts used in the semiconductor industries. We never performed any Taber abrasion testing on these parts.

Marc Green

anodizer - Boise, Idaho

Q. Marc,

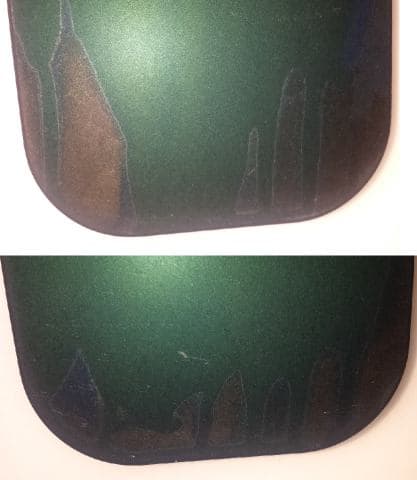

Here are some photos of our black dyed parts in particular. They measure out at 0.7 to 0.8 thousandths thick with our Positector. They look stunning coming out of the dye baths. Is this what sealing smut you were seeing looks like? It's almost as if it's a rainbow, shiny, iridescent color as well though. Any idea what this is? Is this seal smut? We have never seen it before we started sealing in steam.

From the AAC Resource Center:

www.anodizing.org/FAQ/faq_cont2.html

The purple hue is an iridescent color--the result of a very thin film on the surface of the black anodized part. Other iridescent colors can be produced, and can appear even on clear anodized parts, but are most evident on black anodizing. An analogy is a black asphalt road after rain. A droplet of oil causes iridescent rings that are quite apparent on black asphalt but can hardly be seen on a light-colored concrete road.

There are a number of possible causes of the film. One is sealing smut. Hot water sealing blocks the pores of the anodic coating, thus improving its weathering resistance, reducing its adsorptive properties, and sealing in any pigment. However, some sealing product forms on the outer surface of the anodic coating. This is sealing smut. It consists of very small, needle-like crystals of aluminum hydroxide. They act as a thin film that can generate iridescent colors. Anti-smut additives for sealing baths are available, which minimize the problem. The formation of smut can be favored by high pH. The bath chemistry should be controlled as recommended by the supplier of the sealing additive. Alternatively, the smut can be wiped off. Before the invention of anti-smut additives, people used to wipe down parts with lanolin in white spirit. This temporarily masks the smut as much as it removes it. Manual removal is time-consuming and can be hard work.

Anodizing under conditions that are too aggressive can lead to iridescent effects. In particular, if the bath temperature is too high, the surface region of the porous anodic coating (the part of the coating that was first formed during anodizing) can be dissolved in the acid solution to the extent that it is very much more porous. This is called a "soft" coating. In general, anodizing at over 75"F for more than 45 minutes can produce a soft coating. A simple abrasion test to detect a soft coating is described in British Standard 6161: Part 18: 1991.

Also, purple iridescence has been seen with certain types of black dyed parts if the film thickness is too low or the dye bath is inadequately controlled.

- Austin, Texas USA

Yup, that's the same end result I was dealing with, except for mine was much heavier, and my parts were not dyed.

Opinions vary on what exactly seal smut is, but the general consensus seams to say it's Bohmite.

Marc Green

anodizer - Boise, Idaho

Steam Sealing creates smut and streaks where water condenses and drips off

Q. We are having an issue with steam sealing that we have been trying to tackle for a while and are coming up really short on information out there. We use a large autoclave to contain our steam and even after an hour or so preheat, it still takes upwards of 45 minutes from the time we open the unit up and load the rack of parts until the time we can reach our target temperature of about 105 °C. We then proceed to steam seal for one hour. Our parts are type II anodized, dyed and colored parts. Thicknesses come out measuring about 0.7 thousandths. Colors look consistently great going in. The sealing smut is not great but we can remove it manually and I know of no way to remove it unless we switched to a nickel seal plus additives.

The main issue though is that when the parts are inside the steam chamber and the water condenses on the parts and racks (they are held up vertically), the random dripping of water that invariably condenses on the parts causes the drips to interact with the smut (or seal the part somehow differently in those places) and causes these strange lines that persist even after we wipe away the smut. The attached photo shows the orientation of the drips.

The parts are very well sealed everywhere, they just are all cosmetically rejectable. Which is the issue we have now. The only thing we can think of is to speed up how quickly we can get the tank back to temperature but our ability to do so is currently limited.

Has anybody come across anything like this before? We searched through all of the forum posts and almost nobody steam seals at all. We like it because it is suitable for color (unlike a boiling water tanks), doesn't produce any nickel waste and is easier to keep consistent. Plus it is much easier and quicker to heat up a steam chamber than hundred of gallons of water. We could insulate a sealing tank and always keep it hot but that's not terribly desirable either. We also like the added benefit of avoiding the introduction of nickel into our final anodizing and not having to deal with disposal.

There are not much in the way of additives we could use as the steam process would flush them out and we already steam seal with RO/DI water. We currently seal at under 30 PSI. The only thing we can think of to test would be faster steam introduction by using a tank of steam that we introduce as soon as we place the parts inside. I have seen a bit of talk of vacuum treatments being of use in many decades old patent literature but testing doesn't seem to indicate it does anything. We have also tried rinsing with pure DI/RO water specifically before steam sealing, in addition to our normal counterflow rinse processes. Still doesn't fix the issue.

Is what we are seeing related to sulfides that are embedded into the anodize pores? Has anybody seen anything like this before?

Anodizing Shop Employee - Boulder City, Colorado

August 25, 2015

Q, A, or Comment on THIS thread -or- Start a NEW Thread