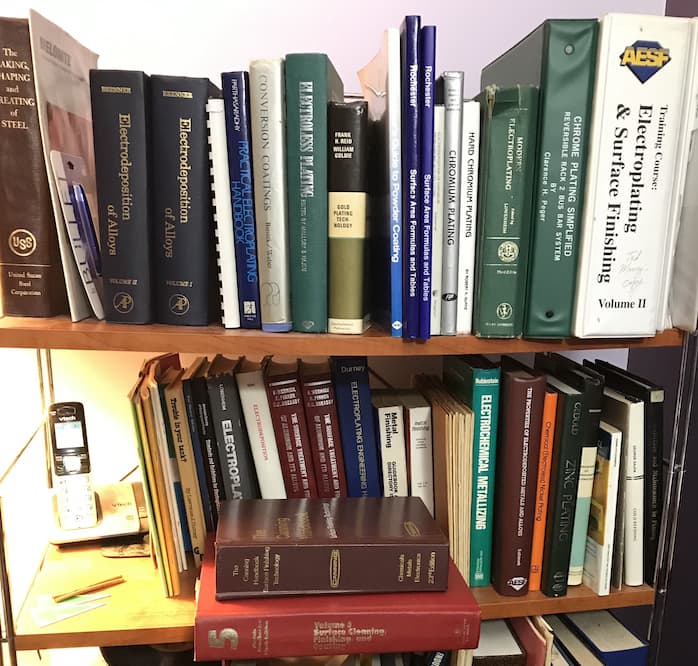

Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Amperage requirements for plating

Q. Hello there!

Can anyone suggest what should be the capacity of the rectifier (in terms of amps) needed to operate a nickel plating tank containing 250 ltrs of solution. the tank is mostly used to plate bright and satin nickel on brass parts.

Any clue would be helpful.

Manufacturing trainee - Moradabad, UP, India

2007

A. Hi, M. You go by square foot to be plated rather than tank size.

50 amps per square foot would be a good number to size for, and 40 ASF would be a pretty typical actual value in use.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

A. Hi Jamal,

Since you said the tank capacity of tank 250 liter but you did not mention how many racks you are going to plate in that I mean what will be the area you will be plating, generally Nickel will be plated at 4 Amps/dm2, based on that you can plan your Rectifier capacity, e.g., 15 volts, 300 Amps or 12 volts, 100 Amps, etc.

Hope this will help you.

Good Luck

Mukesh

Panjala Mukesh

fashion jewelry mfgr.

Hyderabad, India

Q. Dear sir,

I have rectifier of capacity 12 volts & 2500 amperes. Now I want to know how much Kilowatt is the capacity of this rectifier.

This is for the calculation of total kilowatt requirement of our factory.

Kindly help me with this conversion.

Regards

Dharampal

- UAE

January 6, 2010

A. Hi, Dharampal. According to Watt's Law, P = V*I. So the output power of the rectifier is 12*2500, or 30,000 watts or 30 kilowatts.

Rectifiers are not 100 percent efficient, though; let's approximate at 67% until you actually select a rectifier and learn more detail about it. So the input power is about 30/.65 = 45 kilowatts.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Need help choosing hobby electroplating rectifier

Q. I am looking for a rectifier that will allow me to plate gun and rifle parts in copper, nickel, black nickel, chrome and black chrome. I had purchased a 5-15 volt and 25 amp rectifier and what I received was marked 6-15 volt and 25 amp rectifier (which when turned on has a minimum volt reading of 7 volts at lowest setting). After several emails I got the company to take it back. The company told me in their last email I was sent a "Modified" 40 amp rectifier, but after checking their website again I noticed that they rate the max power of their rectifiers under what the call "Surge". My question is this, is "surge mode" safe to plate under. Or is it only good for plating short periods of time? Also, are red lines on the rectifier the maximum limit for safe operation? .

But, the highest amp rectifier is 40 amp that surges to 50 amp. Lastly, does anyone have experience with [brand name deleted by editor] rectifiers? Thanks.

hobbyist - San Antonio, Texas USA

February 29, 2016

A. Hi Oscar. My experience is in industrial electroplating rather than hobby plating, and I've never heard of a "red line" or "surge mode" on an industrial unit. All the rectifiers that I used in almost 5 decades could safely be turned up all the way ... and in fact for most types of rectifiers it is best to plate at the high end of their capacity for the least ripple and the highest efficiency. Surely the vendor can explain their "surge modes" and "red lines".

The largely anonymous internet isn't the place to get brand recommendations, though. For one thing, salespeople pose as satisfied customers, and affiliate marketers get paid for "comment spam". Meanwhile negative comments attract pressure from the companies' lawyers and get removed, all resulting in disproportionately glowing recommendations. There are more reasons we don't suggest brands too ( huh? why?)

Please practice with your copper, nickel, black nickel, and imitation chrome on scrap parts for a few weeks or months if you want to learn this hobby. Plating is dead easy, elementary school kids can do it -- but consistent good plating on difficult substrates is very hard indeed.

I strongly advise you not to buy any chrome plating chemicals; they are toxic and carcinogenic, and billions of dollars have been spent in the last couple of decades cleaning up chrome contamination. However, when hobby plating suppliers offer "chrome" plating chemicals, it's usually not really chrome but some imitation. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. There is a red marked line at 36 amps and 14 volts.

The meters highest values are 40 amps and 20 volts. I noticed that the internal fans kick on whenever the I turn the rectifier up past the redline on the volt meter. I never have turned the amps up high enough to hit 36 amps. But, I still would like to know what size rectifier is best to plate gun parts. Probable the largest piece I would plate is a barrel. Thanks.

Oscar West [returning]- San Antonio, Texas USA

A. Hi again Oscar. Everyone knows what a redline means in general ("Don't operate in this range!"), but only the vendor can tell you exactly what it means for his equipment. My guess is that the maximum capacity of the rectifier is actually at the redlines they drew, and that they simply used 'standard' 40-Amp meters and 20-Volt meters instead of having meters custom built for 36 Amps and 14 Volts.

I would size rectifiers for copper, nickel, and black nickel based on 40 Amps per square foot of surface area to be plated. You must get comfortable calculating/estimating the surface area of things you want to plate because surface area is at the heart of everything in surface finishing.

If you are using a proprietary imitation chrome you need to ask the vendor what current density is required for bright plating, but my guess is 40-50 ASF (real chrome plating requires 4X that much). Best of luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello, going to be plating small acrylic items with 24k gold, my process would be to apply a conductive silver paint, next nickel then gold. I want to be able to brush plate and small electroform rack and tank plate. I want to know what power range of rectifier I would need to do the highest quality of work! Thanks. the items to be plated are no larger than 2" sq.

Todd Oldham- Orange Texas

May 26, 2021

A. Hi Todd. The nickel will need more current than the gold. The rectifier should probably be sized for 40 Amps per square foot of surface area of the work. 6 Volts would probably be enough; but you might as well have more flexibility and buy available 12V or 15V laboratory power supplies rather than go searching for lower voltage units.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 2021

|

|

! Dear Ted. I enjoy, and have enjoyed, reading your responses/posts over the years. Thank you for sharing! How in the heck does so much knowledge reside between just one set of ears? Very impressive! Lupa Khali- Ontario/Canada March 26, 2023

Regards,  Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey |

Q, A, or Comment on THIS thread -or- Start a NEW Thread