Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Gold Plating Problems with Jewelry, How to make gold plating last longer? PVD?

< Prev. page (You're on the last page of this topic)

Q. Hi again

Sorry to bother but how much gold is "10 macro" in mils?

- new york, oregon, usa

December 28, 2017

A. Hi again, our well-traveled friend from Sweden, Los Angeles, Dallas, Oregon, & New York. I don't think there is any such thickness measurement as "macro"; please try to give us an exact quote about the gold thickness, in context. Thanks!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

December 2017

Q. Haha

I ask him how much gold is was plated over and he say: 10-15 macro ?

But then he said: 10- 15 micro that lot of gold?

Do you think it is so much in gold plating for that price? It's cost in dollar about $350-400

- new york, oregon, usa

December 29, 2017

A. Hi Far. "Micro" only means "one millionth". But you can be virtually sure that the thickness is not 10-15 millionths of a meter (10-15 microns) because the world's most expensive gold plated watches aren't even plated that thick these days. So he probably meant 10-15 millionths of an inch, i.e., about 0.25 to 0.38 microns.

Unfortunately, we have no way of knowing whether he was telling the truth, and we do not attempt to evaluate items here anyway. But 0.25 to 0.38 microns is probably typical for costume jewelry / imitation jewelry.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

December 2017

How long do 24k gold electroplated taps last?

Q. Hi as a rule of thumb how long would 24k gold last before showing signs of wear on bathroom taps?

Steven Gaskell- Auckland, New Zealand

January 20, 2018

A. Hi Steven. There is almost surely a clearcoat over the gold plating, and it probably ought to last a few years, according to general expectations of merchantability. Unfortunately I don't think there is any way to hazard a better guess.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

January 2018

A. Hi Steven

Ted is quite right. Clearcoat should last a couple of years. Without it 24 kt gold on its own is thin and very soft.

In my opinion it is a totally unsuitable finish for any domestic surface subject to wear like regular cleaning.

Of course, clearcoat detracts from the appearance of gold and it usually ends up looking like brass.

So why not save a small fortune by just buying clearcoated brass fittings?

Geoff Smith

Hampshire, England

January 23, 2018

Q. Hello

I'm a goldsmith from Istanbul Turkey. After working years on gold and diamond, we have started to take orders in silver and export them to EU. We started our plating journey by very thin flash plating to get 14k gold look but it was too weak and our goods were losing their color. Customer wants on the other hand, they are looking for pieces gold plated to last approximately 1 year. After quick research we found a company whose occupation is micron plating (as they say). The company owner told us that 1 micron would be fair enough for necklaces and earrings and 2 microns for bracelets and rings. They have solved the durability issue of the plating. But we face a color problem every time we give them chain necklaces; nearly half of them come in really dark gold color (sometimes they look they are burnt) while the rest of them have 14k gold shine.

Whenever we discuss this problem with the company owner, he blames the chains:)

What I'm curious about is: are there any possible risks that I mentioned above in micron plating because of a mistake or this company is just faking on our models and doing something different than micron plating. I'm having this problem with 25 percent of the chain necklaces (no matter which design it is)

I have been following this topic for a long time and I have seen there are authorities sharing their valuable gold experiences. I really need help and advice.

Best regards

- Istanbul Turkey

January 29, 2018

Q. I bought a watch with a gold plated band which after only a month became very tarnished. I bought a replacement one today and am fearful that it too will only last a few weeks. Is there anything I can do to keep it looking like gold? Thank you. Bev.

Bev Davis- Brisbane Australia.

March 5, 2018

A. Hi Bev. If you wear it only occasionally, you could wrap it in an anti-tarnish cloth, or put anti-tarnish materials in a drawer with it. But practically, the only thing you can do is make sure you bought a different brand this time.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

March 2018

Q. One of the following solution was given by Ted Mooney, P.E.: "Of the materials you listed, I think a brass or copper base, followed by nickel plating (or white bronze if jewelry), immediately followed by gold plating would be the best choice."

My question is the following: I have a watch case I would like to gold plate, with a home set electrolyte solution, but in the instructions they mention to mirror polish the object because of all the scratches you would notice, but now that I'm going to nickel plate, is this still necessary!?

Patrick Marugg- Corunha, Spain

August 24, 2018

A. Hi Patrick. Modern nickel plating baths are "self leveling", so surfaces that will be nickel plated do not require mirror polishing. But two provisos: first, I am not necessarily sure that a home hobbyist will achieve proper self-leveling unless you have some experience; second, the fact that nickel plating does not require a mirror-finished substrate doesn't mean that it can cover and conceal all scratches; up to a certain depth it will cover them, but beyond that it will emphasize them. If this is an old watch case, chances are it has some scratches which the nickel plating will emphasize rather than cover.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

August 2018

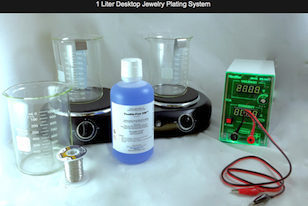

Q. Has anyone had any experience with home plating kits?

I am talking about the complete kit with everything you need to gold plate your jewellery at home.

These kits are around US $3000 with rectifier included, usually it should also include a quart of 24 karat gold solution.

I would love to hear from anyone who has any knowledge on these types of kits as I am seriously thinking of buying one.

Regards,

jewellery inc - melbourne victoria australia

August 20, 2018

A. Hi Kaye.

adv.

Here is a 'kit' from Gold Touch [a finishing.com supporting advertiser] for $499 at the time of writing .

There is really nothing special about the $3000 price range. Electroplating for the purpose of a science experiment can be done at no cost, and with stuff already in your kitchen; and at the other extreme a plating installation for depositing a single metal can cost $10 million or more.

If you have not done plating before, my own feeling is that you should do the kids free science experiment plating first ("Electroplating -- How It Works") to quickly understand the science behind electroplating, at least at a grade school level. I would then consider buying a kit and some copper plating solution and trying some copper plating and clear coating of jewelry. To me, the main issue with gold plating is just that experimenting and trying to learn the basics using a metal which costs $1000 an ounce is a costly way to go :-)

Additional comments are welcome! ... but sorry, we can't post comments mentioning or suggesting specific brands of kits (why?).

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

August 21, 2018

A. Ted is right. Gold is awfully expensive to experiment with; you should start with something simpler.

Does the kit include gold stripper for when you get it wrong? We all do sometimes!

I would want a spill tray for when you break one of those glass beakers (not if).

Do you have cleaning chemicals; and know how to do a water break test?

Do you intend to do a nickel undercoat?

How do you intend to dispose of unwanted chemicals (local regulations) and have you considered first aid when some gets on your skin - or in your eye?

And was that reel of wire in the photo tinned? You should use bare copper to avoid getting tin or lead in the gold.

$3000 is a significant investment. A local plating company could do a lot of work for that.

Geoff Smith

Hampshire, England

![]()

Thank you Geoff and Ted for your advice regarding electroplating at home.

I guess the main impetus for wanting to buy a gold plating kit is that I don't know if I can trust this function to just any old gold plating business.

There's really no way I can judge if they are depositing the right amount of gold specified until it's too late, no?

This forum has given me much too think about re. investing in an expensive plating kit, thank you again.

Regards,

jewellery inc - melbourne australia

October 2, 2018

A. Hi again Kate. Until you've acquired some plating experience there will be no easy way for you to be assured that you applied the required thickness either :-)

Plating shops do plating for medical parts and aerospace ... it's possible to find trustable ones. Ask them for a "cert" (certification) regarding the gold thickness, while you practice with copper electroplating/electroforming. The same equipment you use for copper can be used for nickel and gold after a learning period.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

October 2018

Gold plating turns orange if touched

A. I had some jewelry plated (14k 1 micron thick on some bronze pieces and some sterling silver pieces) by a major US gold plating company and when I received the pieces they turned orange almost immediately after contact. When I contacted them about that they said that was oil from my hands and it would wash off. When I washed them with soap and water the dark orange marks seemed to mostly go away. But then the second I touch them again (even with clean hands) they darken again. Now about 2 months later they are all orange (looks like tarnish) which does not go away with washing them or even using a tarnish remover.

I've only had pieces plated with this particular company, so I'm unsure if this is how gold plated jewelry always reacts, or if this is strange. Should I expect this? Should I ask for something different? Does anyone have a gold plating company that you would recommend for this?

Thanks!

- Alexandria, Virginia

November 2, 2018

A. Hello Aran, did the plating company use a barrier plate (diffusion barrier)? There are a few things to consider. If the company you chose did not use a barrier plate between the brass and the gold the brass will migrate through the gold and cause the color change. If the gold plating is too thin, migration is accelerated. The plater should have told you barrier plates are commonly used for gold over brass. If they plate copper over the brass before the gold the same scenario will take place.

Mark BakerElectronics plating - Phoenix Arizona USA

November 6, 2018

Q. Hi,

I sell wedding rings, typically, sterling silver and titanium steel, gold plated titanium steel rings and gold layered brass rings.

Now the thing is we are in a very hot and humid climate, West Africa and the gold plated and layered rings do not hold up very long before losing their colour, 1-2 months.

My question is, if I rhodium plate the gold layered brass rings, would it last longer, hopefully up to a year or two? Also, can you recommend any reliable vendors who can supply real gold filled rings? Thanks!

Bridal Jewelry - Lagos, Nigeria

December 25, 2018

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Hi Zee. Rhodium is only for silver or white gold rings because it is silvery color. It is not an answer for yellow rings.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

December 2018

Q. We are in the process of developing a high end product that is to be gold plated for ensuring a service life of about 30 years. Our plater/chemistry supplier has recommended 25 microns of hard gold plating with gold purity of about 99.5%.

We believe this thickness and the hard gold plating will take care of the wear issues for this application. However we are keen to address the porosity issues.

Is it a good idea to have a thin layer of soft gold on Ni barrier and then the hard gold to ensure zero porosity?

Also by adding this soft gold layer, will we get better flexibility of the hard gold layer on top - or rather reduce brittleness of the complete plating solution?

Percept - decorative coatings - cairo, egypt

January 26, 2019

A. Hello Ibrahim, with hard gold plating of 25 microns you won't have any porosity issues. With that thickness the pores will be closed. I've never had to plate gold over 100 microinches, and you would be approaching 1000 microinches. You would be at the very high end of the gold plating thickness spectrum. The oil and gas industry often require greater gold thicknesses, as well as atmospheric condition considerations. A gold strike bath is employed by many shops to improve adhesion of the top gold layer and reduces drag in of metallic contaminants to the main gold plating bath. The strike bath is a low metal concentration bath without any alloys. Be very careful of brittleness in the deposit. Have some bend tests done on a regular basis. As gold purity decreases the deposit is less malleable. Good luck in your venture.

Mark BakerElectronic Plating - Phoenix, Arizona USA

January 29, 2019

Q. Thanks Mark! You mention about brittleness. Actually we are concerned about this as well. As mentioned in my initial query, would the soft gold under layer of about 1 micron help with any brittleness issues?

Also, the purity of the hard gold layer would be about 99.5%. At this purity too, should we be worried about brittleness?

Also, I'm not sure what the other metal will be used by the plater that would offer the hardness of about 250 vickers (as claimed by the plater). if I may tap into your experience, which metal would be best to alloy with gold to allow about 250 vickers hardness, and yet maintain a high purity as mentioned above?

Percept - decorative coatings - cairo, egypt

January 29, 2019

A. Hi Ibrahim

I have electroformed many parts in a standard nickel hardened acid gold (Metalor) to a thickness of 1 mm

There was never any sign of brittleness.

It is usually accepted that over 5 microns there is no porosity or diffusion issues.

Geoff Smith

Hampshire, England

January 29, 2019

A. Hello again Ibraham, your parts being brittle depends on how clean the plater keeps their gold bath. As other metal contaminants are introduced into the bath through drag in, the gold purity drops and could result in parts being brittle. If good rinsing and good housekeeping is employed there should be no problem. A pure gold plate under the hard gold would not make any difference as far as parts being brittle. You can ask your plater if his gold bath supplier regularly checks for metallic contaminants when they do routine analysis. Good luck!

Mark BakerElectronic Plating - Phoenix, Arizona USA

January 30, 2019

Q. Hi everyone, I need your assistance. I've been reading this forum for some time and found it extremely useful so I'm hoping you can help.

I received my samples of 18k gold plated vermeil (2.5 micron on 925), no e-coating. However after a month of wearing it a rosegold/more copper like colour was coming through. I went back to my supplier and they said they put a flash layer of 23k on top as it reflects the gold colour desired, but underneath is 18k which has more copper. They said this is normal for EVERY supplier (I've asked them to ask multiple) and once this flash layer comes off a different more coppery colour will always show.

Firstly is this normal? I have requested the 18k to have a lower % of copper to ensure it isn't on the verge of Rosegold % mixes.

Secondly, your advice may be to simply add a e-coating, however once I receive my products I engraved fingerprints (of customer loved ones) on the pendant. My supplier tells me I can't add e-coating before as the engraving will go WHITE and be rough. Is this right?

Any advice on the above would be appreciated

- Sydney, NSW, Australia

June 23, 2019

A. Hi Rosie. Vermeil is very high quality jewelry and should not require e-coating. I have heard of 'gold coloring' which involves putting a final layer of the exact color you want on top of a substantial layer of regular gold plating, however, it usually runs the exact opposite way of what you describe. Usually a heavy coating of yellow gold might be 'colored' rose or green via a thin top coating.

Your vendor's story isn't ringing true for me. It sounds to me like he has an inventory of rose gold (instead of yellow gold) pieces that he is offering to you by applying a final topcoat of yellow gold. I don't think you should normally have to worry about vermeil changing color even in years or decades ... let's see if an experienced jewelry plater can say something :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 2019

|

Q. When you say Rose Gold inventory, are you meaning they are potentially using Rose Gold Plating, then using flash 23k, or are you meaning they may be using Rose Gold instead of Sterling Silver as a base. Due to Rose Gold being a mix v.s the starting point, I assume you mean the former? Looking forward to hearing other opinions, as I need a professional opinion to go back with. I'm not feeling their story either Ted. Rosie Bunton [returning]- Sydney, NSW, Australia June 23, 2019 A. Yes, I agree with Ted. In addition, there is really no reason to build the vermeil gold thickness with an 18K alloy and certainly not a copper alloy. To qualify as vermeil the 2.5 micron thickness is pure gold or equivalent. So the thickness of 18K gold alloy will have to be much thicker than 2.5 microns to meet the standard. Neil BellAlbuquerque, New Mexico June 24, 2019 |

![]() Thanks Neil!

Thanks Neil!

A. Hi again, Rosie. I'm only suggesting the possibility that they perhaps may have had a stock of rose gold plated items and decided to meet your need by putting a flash of yellow gold on top of that. But I'm not claiming that these parts, which I haven't even seen, do or don't meet the quality standard for vermeil.

Speaking as a former 'expert witness' on a half dozen or more court cases in the USA though, I unfortunately must inform you that nothing you can read on the internet will ever constitute "a professional opinion". I doubt you would take legal action on "samples", but to do so you must retain the services of an expert; the opposing side will then challenge his/her credentials and the judge will rule. If any volume is involved, you probably should get a jeweler to evaluate just exactly what you received. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 2019

Q. Hi I'm new in this. I want to know is 0.25 m better plating than 0.03? Will it Last long?

Jose davila- Kissimmee Florida

July 22, 2019

A. Hi Jose. It sounds like you are trying to judge the quality of some jewelry from its seller's sales pap, and that usually doesn't work :-)

"0.25 m" obviously doesn't mean meters. Maybe it means "microns" to you? 1 µ thickness used to be considered fairly good quality costume jewelry. In fact, it was frequently just called "micron jewelry". These days 1 micron is probably hard to find in the mass market, so I guess I'd call 0.25 µ thickness (10 microinches) "okay" quality. 0.03 µ seems almost impossibly thin -- are you sure what units 0.03 was referring to?

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 2019

Q. Hi, I have been reading the entire thread and wanted to run by some details before I place my order with a china factory to produce a bangle.

What I am looking to produce is a gold quality that will last more than a year without any gold color fading. Please help me phrase this properly and advise the best option from your expertise so that my terms and description is well stated so the factory understands my needs:

Option 1: Stainless steel base, then TiN by PVD 1 micron undercoating before gold plating of 14k or 18k hard gold coating 3 micron. The last electroplating layer.

Option 2: copper base l, layer of palladium, 3 microns of 18k hard gold plating, last layer TiN 1 micron gold color

Option 3: sterling silver base, second layer of palladium, last layer 3 microns of gold plating.

- West Africa

September 3, 2019

A. Hi Pat. My opinion is only my opinion, but I would not proceed on a project that way. Proceeding based on theory alone is something you do only on moonshots when testing is impossible and you have a large budget and can pay the best people in the world to do detailed research. Plus, neither you nor I is an expert on bangles -- the shops who make and plate countless thousands of them are; I could suggest that copper is easy to plate, only to have you find the bangles ripping off their chains because it was too soft. Finally, if they do a poor job you probably have no realistic recourse no matter what you spec'd anyway.

I would only work with a manufacturer I trusted and I'd ask them what they recommend. Good luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 2020

Q. Hi Ted and co, I wrote on here a while ago about my 2.5 micron gold plated gold pendant has become oxidized, that the gold had started to change colour. We also had necklaces done but they had an e-coating over the top and have not oxidized.

I originally wanted to put e-coating on our smooth 18mm x 2m gold plated pendant, however our supplier said if we did that, the engraving we put on after would be ruined. However I have researched many other brands and they seem to engrave initials etc over plated pendants with a clear lacquer.

For context we engrave fingerprints of our customers loved ones on pendants.

So my question - is my supplier correct when they say adding e-coating on top of 2.5 micron pendant will ruin the engraving - which would be done after?

Jewellery - Sydney, Australia

October 5, 2019

A. Hi Rosie.

Things are sometimes a matter of scale. Even fairly small engraving of initials, trademarks, etc., strike me as much much bigger than the ridges on fingerprints. Although I'm not sure that I fully understand, I can certainly believe your supplier.

However, what I still absolutely do not understand is any need to clearcoat vermeil :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Please assist:

I just started my business this month, gold plated women's accessories, most of the designs are Alloy. The problem is after using it for a few times in hot weather it turns black, with green line on the neck -- why is that? How can I avoid that and get better quality? Can pay more for better quality, but how to be sure.

- UAE

June 1, 2020

? How thick is the gold? Do you have a diffusion barrier (nickel or palladium) under the gold?

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

June 8, 2020

A. Firstly, what purity gold are you depositing? Secondly, what is the alloy base? Thirdly, how thick is the gold? Fourthly, do you have any interlayers between the gold topcoat and the alloy base?

It sounds to me like you have too thinner gold layer and it is porous. The black and green could come from the alloy base or any interlayer you chose to use. However, to give a more comprehensive answer, you need to give more details.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

June 8, 2020

Q. Hello, I am starting a jewelry business and I was looking at the jewelry I want to sell. My question is how long does a sterling silver coated with 0.25 microns gold last for?

Sylvanus Edi- Anchorage, Alaska

December 24, 2020

A. Hi Sylvanus. First off, I'm no jewelry expert and this is just 'book knowledge', I'm just trying to offer the courtesy of a reply -- so I certainly encourage others to chime in.

I don't think there is an answer to your question because rings suffer extreme wear; bracelets probably quite a bit less, but still an awful lot; necklaces and earrings less than that; and pins and broaches almost none. And that's before we even consider that different people treat their stuff much differently, for example, swimming and washing dishes with rings on vs. off.

But one answer is that 0.25 microns is ten millionths of an inch, and standard aluminum foil is 63X thicker. So without a clear coat it probably won't last long except in a very low-wear situation. A clear coat is probably called for.

Perhaps a better answer is by comparison to other jewelry. I believe that the cheapest gold plated jewelry you will find anywhere is about 0.06 microns; this is probably just enough for a gold color and is used under a clear coat. Your thickness of 0.25 is probably similar to most average quality costume jewelry these days. "Better quality" costume jewelry is sometimes called "micron gold" because it is 1 micron (4X your thickness) and that was probably the typical thickness several decades ago. Vermeil is about the highest quality non-karat jewelry you'll find, and is 2.5 microns thick on sterling silver. The gold plating on super premium watches was reportedly about 7 microns (although today they probably use titanium nitride as well as gold to prolong the life, so the gold thickness might be less).

So I think the question of how long will it last is not answerable, but the question of where you will fit in on the quality scale is :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

December 2020

January 5, 2021

Q. Hello! This thread has been unbelievably informative, I read all the way from the beginning. I am just starting my own line of 'Demi fine jewellery' and I will be outsourcing production. Like many others, I want to do the next best thing after solid gold.

- My first option is Gold-filled. Ideally with silver base (so it's a much thicker vermeil)

- However, because gold-filled has limitations (for example, you can't cast), my other preference is vermeil.

My two options I'd like to try for my vermeil jewellery are:

1. 10 microns of 14k gold/rose gold on sterling silver base

2. An initial coating (say 2 microns) of TiN, followed by 2-3 microns of 14k gold/rose gold on sterling silver base. This may not be possible initially due to quantity, but I'm happy to pay a premium

My questions are:

a) Which of the two (1 or 2) do you think would give me jewellery the best chance at lasting as long as possible? Say 2 - 5 years?

b) Do I need a nickel coating on top of sterling silver for option 1?

c) I was considering going up to 20 microns for everyday necklaces for example. Will this have significant improvement over 10 microns?

Thank you in advance for your help!

- London, UK

A. Hi FK. I'm all for quality, even super quality, but vermeil is 2-1/2 microns and would probably last a decade on a necklace. I can't swear to it, but I've heard that the world's finest super-premium watches were using 7 microns of gold until TiN became available, so it's probably TiN plus a couple of microns of gold these days.

Although silver & gold interdiffuse, it's a slow process at room temperature, and probably not a serious concern for vermeil or greater gold plating thicknesses (my opinion based on my limited experience; always get multiple opinions on matters of this import), but for thin gold the nickel or other bright plating underlayer is required for brightness as well as to stop diffusion.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 2021

Hello, I'm starting a Jewelry business. I'm going to make an Sterling Silver with gold plating, I want to make good quality with the cheap cost to help my budget and they offered me 0.05 gold plating micro, what do you recommend? I need your advice, is that fine to make jewelries with this unit? And will the color last and won't vanish over time if used carefully ?

Sama Ahmed- UAE

July 24, 2021

A. Hi Sama. First things first, I'm not 100% sure what you mean by "0.05 gold plating micro", but if it means 1/20th of a micron of gold plating, I think it's silly to use expensive sterling silver as the substrate for very cheap jewelry ... and you'll probably need nickel plating below it, and surely a good clear coat on top of it anyway if you want it to last a couple of months.

I certainly can't call it "good quality" when the vermeil that FK feels is too thin for his high quality jewelry is 50X as thick. "Good quality" is a matter of personal opinion, but mine if that 1 micron (40 millionths of an inch) is "good quality" :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread