Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Salt Spray Testing of ZAMAK plated with Nickel-Chrome

Q. Hi all,

We are planning to manufacture some ZAMAK parts with nickel chrome, the parts must have a good corrosion resistance and a lasting fine shiny looking also.So we really needs to know what tests do we have to do on the products to be sure that those 2 goals will be met?

Some people have suggested ASTM B117 or CASS tests (ASTM B368) -- are those the right tests we need? If yes how can we do them?

Your response would be greatly appreciated

Thank you.

Plastics Manufacturing - Cairo, Egypt

2006

|

A. Hi, - Toronto, ON, Canada 2006 Q. Dear Sridhar, Plastics Manufacturing - Cairo, Egypt 2006 |

QUICKSTART: Salt spray / salt fog is a popular accelerated testing procedure, and is most often conducted in accord with ASTM B117. However, there are many tweaks to the test or alternatives to it which some feel are more representative for particular substrates, coatings, or circumstances and CASS (copper accelerated salt spray) is one such. |

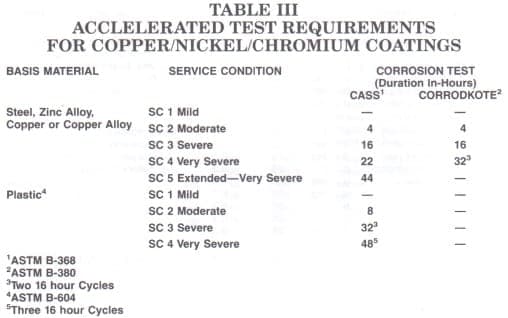

A. Hi Mansour. Yes, CASS Testing or Corrodkote (ASTM B380) testing are generally considered more representative for testing nickel-chrome plating than the astmbASTM B117 Salt Spray Test. You may wish to obtain a copy of the MFSA's Quality Metal Finishing Guide from NASF at www.nasf.org; it's only a few dollars a copy. Here is a brief excerpt on the issue:

Good luck, and Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

February 2014

Q, A, or Comment on THIS thread -or- Start a NEW Thread