Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Plating onto Carbon Fiber: applications, methods, Q&As

Q. Hi,

My google search is failing; so, I'm jumping here to ask a few questions that may be obvious to members of this community. Please bear with me as the questions are related ...

I see carbon fiber linear rails for cameras:

https://www.bhphotovideo.com/c/product/1514487-REG/gvm_gp_80fw_flywheel_professional_video.html

1) Is there a "mechanical" reason why linear carbon fiber rails are not used in 3d printers to reduce the inertia/momentum of the moving head?

2) Would I assume correctly that the resin on carbon fiber tubes would suffer wear under u-shaped metal roller bearings?

3) Assuming the above (#2) is true, would nickel or chrome electroplating CF tube offer more resistance? What metal would you suggest for coating (if any).

I'm thinking of creating a test rig to see if it is a viable option; but, I'm unable to find a metal-coated carbon fiber tube.

4) Can I assume carbon fiber tubes are conductive for electroplating? If not, what is a recommended way of preparing the surface for electroplating?

Thank you in advance.

-Edvin

- Turlock California

July 27, 2021

A. Hi Edvin.

1. Sorry I don't know enough about the design and inertia issues of 3-D printers to know whether carbon fiber rails would offer advantages.

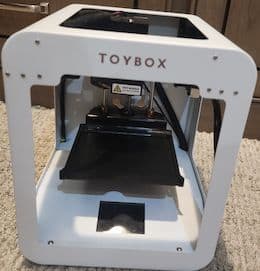

2. Yes, carbon fiber rails would surely be quickly destroyed by the hardened balls of traditional linear bearings. I've included a photo from the page you mentioned to show the readers the way that device is carefully designed to avoid heavy loads or wear on the carbon fiber rails:

4. If the rails in question are small and cylindrical, electroplating might possibly afford a bit of "shrink-wrap" effect to hold it in place; but in general, the main issue in plating something is not making it conductive, but in assuring good adhesion to avoid blistering, peeling, etc. Thus, it's usually involves excellent cleaning, etching, and a metallizing method like palladium seeding followed by electroless plating before the electroplating.

There are more than a dozen threads on this site about plating of carbon fiber if you have time to search the site.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

⇩ Related postings, oldest first ⇩

Q. Looking to plate carbon fiber molded piece. Application is medical, but any type of plating info would be helpful.

Anthony La RosaDesign - Parsippany, New Jersey

2005

A. Hi Anthony. Nickel plating is pretty common and is also discussed in its own thread: thread 31436, "Nickel electroplating on carbon fiber". Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Chroming Carbon-Fiber Hydraulic Cylinders

Q. I have come by this site while looking into a design issue we have. I hope there's someone who may have a few words of advice.

ACRONYMS:

CFRP = carbon fiber reinforced plastic

Amongst other things, we manufacture carbon-fiber hydraulic cylinders. The barrel is essentially a steel liner wrapped in CFRP. We would like to chrome plate the steel bore, after it has been wrapped. Can someone tell me whether there are any problems/issues with this? For example, interaction at the interface between the steel liner and the CFRP?

Extending the concept slightly, can any chrome-plating experts tell me whether it is possible to put a durable chrome surface on the CFRP directly? Are there any examples of chrome-plated CFRP to demonstrate the point?

Thanks in advance!

Mark Fahey- Germany

2000

A. Hi Mark. As for plating the CFRP itself:

Virtually anything can be electroplated, from orchids & maple leaves to the chrome-plated grills on tens of millions of automobiles.

However, what usually determines the acceptability of plating a non-conductive surface is whether you can get sufficient adhesion for engineering purposes; and the robust pretreatment processes required to enable this may only be available only for certain substrates. I know that ABS, polypropylene, and some grades of glass-reinforced nylon can be very robustly electroplated; while carbon-fiber reinforced plastics are successfully plated, I'm really not sure if the plating is robust enough for a hydraulic cylinder (and I imagine that it would be more dependent on the resin system that bonds the fibers together than on the carbon).

You would probably need to do a full sequence of electroless plating followed by copper, nickel, and chrome rather than straight hard chrome plating.

As for plating the steel liner instead:

You would surely be better off figuring out a manufacturing sequence that would allow you to plate the bore of the steel shell before you wrapped it with the CFRP. The chemicals required for cleaning, activating, and chrome plating the shell are pretty aggressive and, yes, you would need to concern yourself with the CFRP's resistance to them. It's not necessarily impossible to plate them afterwards, but from this distance it strikes me as far less practical than plating the shell first. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. If you do an internet search for "electroplated 3D Carbon Fiber Film" you will find many suppliers selling pre chrome plated fiber material; perhaps you could go that way. You could avoid environmental and health issues.

Charles Hubert- Collinsville, Illinois, USA

March 22, 2013

Copper plating on carbon fiber

Q. I am an aspiring amateur rocketry hobbyist.

One idea I have for construction of an engine/nozzle is a carbon fiber and copper composite material. I know this has been done through impregnation with molten Cu but there are wetting issues and the bond is not satisfactory.

Is it possible to deposit the copper on carbon fiber through plating? Also, is there a limit to the thickness of the copper plating?

Any information is welcome.

- Northridge, California, United States

2001

Q. We intend to use carbon fiber tubing for antenna elements. Is there a a way to copper coat that material using a solution or paint? we need to maintain the conductive properties of the copper. Aluminum would work as well.

Martin CooperSystems Engineer - Pennsylvania

June 5, 2009

A. Yes, you can do the coating of Nickel or Copper onto carbon fibers by electroless deposition method or CVD (chemical vapor deposition) method.

CVD is a bit expensive. Electroless deposition is a simple method . For Ni coating you would require a salt - nickel sulphate , a reducer

- sodium hypophosphite, complexing agents , stabilizing agents, pH adjustors, etc.

- India

A. There are some proprietary electroless copper plating solutions that work quite well, though electroless copper plating baths are a bit less forgiving that electroless nickel when it comes to maintaining the chemistry.

What quantity of material are you looking to produce?

fiber plating - West Haven, Connecticut

Plating Carbon Fiber tubes for pressurized nitrous oxide use?

Q. Hello,

I'm a graduate student at Utah State University, working on a project planning on building and flying a sounding rocket to go to approx. 100,000 ft altitude for research purposes. We're planning on powering the rocket with a nitrous oxide / HTPB Hybrid motor, but we're having difficulties finding any lightweight tanks suitable for nitrous oxide use.

Since the body of the rocket is going to be made from a carbon-fiber composite tube of considerable strength (which we do have a supplier for), the idea came up to use a section of the rocket body itself as the oxidizer tank, plug both ends with properly sized and secured bulkheads, and seal the interior against permeation by the N2O. We're leery of using polyethylene or similar, as mixing a hydrocarbon-based plastic with an oxidizer is a sure recipe for disaster.

Would it be feasible to plate the interior, to form a leak/permeation barrier? I realize that we're venturing into unfamiliar and potentially dangerous territory here, but we're aware of the risks and have experience with hazardous materials and testing.

Some of the problems I foresee:

1) Carbon fiber is neither electrically conductive nor metallic, so some type of silver/copper paint would have to be applied first. And even then, there might be a risk of dissolving the composite matrix of the tube.

2) We'd be plating the interior of a pressure vessel; ideally we'd only have access to the inside through 1-2 piping attachments. And it will eventually be pressurized to ~1000 psi; the plating would have to be ductile enough to withstand some expansion of the tank without leaking, especially near the edges of the bulkheads.

3) Nitrous oxide is an oxidizer, and has a nasty habit of exothermically decomposing in the presence of a catalyst and high temperatures. Unfortunately, the vast majority of transition metals (columns 3-12 on the periodic table) can act as catalysts, including nickel, copper, silver, platinum, and gold (all popular plating metals). The safest materials are aluminum and stainless steel, neither of which (from what I understand) is very easy to plate. I am interested in the possibility of using Tin [alloy?], though, as it shouldn't react with the nitrous oxide in any way.

Sorry the explanation was so long, if anyone has any input, suggestions, or portents of doom, please let me know!

Graduate Researcher - Logan, Utah, USA

October 26, 2010

A. A company that I worked for many years ago made spherical shaped tanks out of thin titanium. High strength and low weight. I look at plating the inside of an enclosed body as being extremely difficult and nearly impossible to control quality/inspections.

James Watts- Navarre, Florida

October 28, 2010

Coating carbon fiber with Sendust alloy

Q. I would like to know the best way how to coat carbon fiber with sendust alloy? Electro or Electroless?

Lee Jong gil- Incheon

February 3, 2014

A. Hello Lee. If I understand correctly, Sendust is an alloy of about 85% iron, 9% silicon, and 6% aluminum. As such, I would be very surprised if it was electro-depositable or electrolessly depositable.

If you search for "electrodeposit sendust", while I don't think you'll find out how to do quite that, I think you will find patents which claim to offer similar benefits either by sputtering of sendust-like alloys, or by depositing composites which offer both good magnetic properties and good wear resistance. Best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Is it possible to electroplate gold onto a carbon electrode?

Q. Hello

I am currently interested in electroplating gold onto the surface of a carbon electrode. I have a typical gold - cyanide solution available and I was wondering what parameters / technique could I use in order to plate a layer of gold onto the surface of the carbon electrode. I've had success with plating gold onto gold, however, carbon is proving more difficult.

If it's not possible to directly electroplate gold, is it possible to electroplate a metal to the surface of carbon, then subsequently plate the gold to that metal?

Gracias

GT

- Barcelona, Spain.

November 17, 2016

A. Plating gold to a carbon cathode should be as easy as other common metals like copper, nickel, but remember that the gold layer is so thin that you would have a hard time picking up the color from the dark matte finish of the carbon rod; in your case you can electro plate that carbon cathode with copper then nickel. That way the thin layer of gold will be visible with the nickel background.

Marvin Sevilla- Managua, Nicaragua

Q. I see pro's and con's for plating onto carbon fiber substrate, but I have a general question.

How durable is the carbon fiber (and it's epoxy or alternative-type binder base) to standing up to harsh heated hydroxide and cyanide baths?

Is this just trial and error to find the correct substrate or is there a chance that chemicals from the binder would contaminate the cleaning / plating baths themselves?

Thanks!

Dawn

- Bellaire, Michigan USA

January 30, 2017

A. Please take a look at this list with Chemical Resistance Guide for Carbon Fiber Grids.

http://www.chomarat.com/wp-content/uploads/2011/06/CHO-3265-Chemical-Resistance-Guide.pdf

- Managua Nicaragua

Q. Thanks Marvin,

I did find that link before I posted here. Our bath is caustic and the NaOH is listed as a "B" level grade, but the NaCN is not. Is there any data showing if the CN would cause the CF or the epoxy binder to degrade?

Our interest is in using this material for possible new fixturing, not for an actual working piece. It would have repeated long exposure to our plating bath at higher temps.

My concern isn't so much in the degradation of the C-Fiber itself, but what contamination risk potential it could pose for the bath (due to the binders used). We have a *very* large volume and I cannot risk having to dump and re-make.

Thanks again,

Dawn

- Bellaire, Michigan USA

A. Much of the research done on Cyanide oxidation and gold electrowinning from Cyanide bath using Activated Carbon Fiber Cathodes fail to show any concerns about contaminations from the binders at high temperature, mostly because carbon fiber is one of the most durable composite known and because any lose substrate from the cathode can be removed using simple filtration.

https://www.ncbi.nlm.nih.gov/pubmed/27505273

- Managua, Nicaragua

Q, A, or Comment on THIS thread -or- Start a NEW Thread