Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Masking areas during chrome plating process

Q. Dear sirs:

I would appreciate if someone can indicate me what kind of lacquer I can use to mask parts before they are hard chrome plated. Also what kind of pigment I must add to it to give it a colour in order to visually inspect the application before the chrome process.

Thanks in advance.

Oscar Infante- Santiago, Chile

2001

A. Dear Oscar,

These masking lacquers are usually called "stop-off" lacquers. They are usually nitrocellulose based, and a little thicker than spraying viscosities. You can mill any pigment you want, most common I see are orange and green. If you don't want any color, you can add an ultra-violet pigment, and inspect the coating under a UV light.

Good luck

Jake KochG. J. Nikolas &Co.,Inc.

Bellwood, Illinois

2001

Q. Dear Jake:

Thanks very much for your advise, only one question, by nitro lacquer you mean the kind that are usually applied over wood?

Best regards,

Oscar Infante [returning]- Santiago, Chile

2001

A. Hello Oscar,

Yes, many wood lacquers are made from nitrocellulose, as well as many metal lacquers. This is a cheaper coating to make, you might be able to use a wood lacquer to stop the conductivity on your piece, just need to make sure it adheres well to the metal.

Good luck.

Jake KochG. J. Nikolas &Co.,Inc.

Bellwood, Illinois

2001

Q. We have a hard chrome plating process implemented to chrome the valve stems in the area where later the valve guide is.

The process function himself is:

The parts hang in racks, one border for the chrome layer is(to the tip) is the protected stem by rubber parts the other border is the bath surface from the chrome acid.

Because of the moving bath by bubbles the parts have chrome residuals in the area of the under-head which we had to remove by grinding operations.

We search for variants of covering this area with paint or other removable things.

Udo Hirnschalengine parts - Halver, NRW, Germany

2004

A. Using a maskant for chrome plating is very common and provides excellent resistance to chromic acid and good definition for plating. Most maskants are solvent base and can be applied by dipping, brush or spray. We have seen two new developments for masking hard chrome plating, water-based that is easily removed by peeling and solvent based that can also be removed by peeling.

The disadvantage to water-based is the longer drying time but it eliminates all solvent emission problems as well as other hazards associated with solvents.

Dayton Dailey- Lake Zurich, Illinois

2004

? Udo,

To clarify your difficulty : the "chrome residuals in the area of the under-head" : is it deposition of chrome plate or is it a residual of chromic acid / stain / rust?

Also, what type of valve & alloy is this residual occurring on? What quantities of valves are plated with this problem? Could the valve under-head be blasted with a soft stainless steel shot to remove the residual as an alternative method to remove?

Tim DeakinNorth Tonawanda, New York

2004

Q. I have a problem with areas plating that are masked. I have been using a wax as a maskant, but the masked area seems to plate. What options do I have? I am plating aluminum.

Also, what is causing these areas to plate?

- McKeesport, Pennsylvania

2007

A. Is it that the plating is growing beyond the metal boundaries? In such case that plate would be totally loose and non-adherent, which is frequent and not a problem. Or is the wax lifting up or totally coming off? Then you'd have to review the masking procedure and material quality. I am sure you know that most materials do not adhere well to aluminum unless its surface is prepared adequately.

Guillermo MarrufoMonterrey, NL, Mexico

2007

June 28, 2008

Q. Upon replacement of the seals on the lower gear section of my outboard motor, I noticed that the shaft surface that the seal lip touched had several small "blisters" on its surface. I have made an assumption that this area has been "hard chromed". I polished the area with a diamond stone (it was very slow going) and noticed two things: the tops of the blisters popped off and there was an appearance of slight corrosion underneath the blister AND the area adjacent to the seal surface had a different color to it. Examination under 60X showed a plated area approximately 1" wide on a diameter of 1.125". The adjacent areas on either side of the seal contact area show no appearance of a plating.

Again, I am going to make the assumption that the seal contact area will need to be ground down to remove the existing plating and some sort of resist would need to be applied to the shaft (one shaft is 16" long and the other is about 30" long and both of them exhibit the same problem). How is a resist applied or is a resist applied? How is that seal contact area plated without plating the rest of the shaft? It appears that the plating is ~ .002" thick. Is this process something a regular hard plating shop will do or do I have to seek out a specialist?

Some further information based upon more assumptions: the shafts are either some form of steel or stainless steel: I did a magnet test and both shafts had magnetic properties. The shafts were made in 1987 (the blisters make me wonder about hydrogen, perhaps during the plating process, escaping over a long time and causing the blisters?). The at least some portion of the shafts is relatively soft as a file will bite into the metal.

I guess these are my questions for now. Any help or guidance would be greatly appreciated.

Regards,

Jim Moss

Horological Conservator and 1st time outboard fixer!

Clockmaker, hobbyist - Boxborough, Massachusetts

A. Hi ,

the areas that do not need replating would be masked off with lead tape , and wax .

you said the plating thickness is about .002 , so you would require a heavier deposit to be plated to allow for grinding .

The blisters are due to corrosion, so the area will need do be stripped of plating , and cleaned prior to re-plating.

hope this helps,

- Essex, UK

July 2, 2008

July 2, 2008

This sounds like a simple job for a hard chrome plater. He may use plastic tape, metal tape, or a wax or paint for masking.

Grind it just to remove the old plating, then give the plater the necessary dimensions so he can plate it slightly oversize and you can grind back to the correct dimension. You'll need diamond grinding wheels, plenty of coolant, and about .0001" per pass.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

July 6, 2008

Thanks to both of you for your answers. I have a couple of follow-up questions if you don't mind:

1. What type of wax?

2. Is the masking something that I can do (I am a very skilled clockmaker and a machinist and I am VERY procedural and pay a great attention to detail)?

3. If I can do the masking myself, do you have any recommendations where I could purchase the lead tape and the wax?

4. Is there a reference book that would explain the process of masking.

5. If properly applied, is there any way to guarantee that the plating would not occur in unwanted areas (this is a question about the integrity of the masking or resist). Are there any tests that can be made to determine the integrity of the coatings?

I guess that's it for now.

Again, thank you.

- Boxborough, Massachusetts

The tapes, waxes and paints which a hard chrome plater uses are specially designed for the purpose and require at least a bit of expertise in their application. Which one any plater uses will depend on the specific process used by the plating shop.

The masking cost is a small part of the overall cost.

I don't think any plater will guarantee against leaking if you apply the maskant. In fact he will probably refuse the job.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

July 7, 2008

July 8, 2008

Jeffery,

I wasn't trying to cut into a platers profit, I just thought that they usually are into production and would not want to do a one off and if I handed them a shaft ready to go, they would have less to argue about. :-)

The cost is not a consideration for me: getting the damn boat in the water before I die is!

Jim

- Boxborough, Massachusetts

A. Hi , it would be pointless you trying to do the masking because in most cases I'm sure the company wouldn't accept it in case anything went wrong due to the masking breaking down etc.. plus the cost of the materials would probably cost you more than the cost of having the part masked and plated anyway !

I suggest you just take it to a plating company and let them do all the work for you .

It sounds like a simple , straight forward job !

I'm sure you'll soon be in the water , enjoying yourself !

Hope this helps.

- Essex, UK

July 14, 2008

If there is no friction and the purpose is just to protect from corrosion a cheaper nickel will do.

Khair Shishani

aircraft maintenance - Al Ain, UAE

July 24, 2008

Q. Whether nitrocellulose lacquer will withstand the plating temp 50 to 60 °C and long duration of plating (almost 8 to 10 hrs)?

Shrikant Nigade- Mumbai, India

September 28, 2009

RFQ: I need supplier of this lacquer available in South India.

Please contact.

It will very much useful for me.

Thanks

Sakthi

- Coimbatore , Tamilnadu India

January 22, 2013

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Hi,

I Have a requirement of ID Chrome Coating inside cylinder not full length, middle portion of Cylinder, so I need to mask rest of area.

oil field supply Center - Dubai, UAE

June 26, 2019

A. Hi Shabeer. Sorry, but that's pretty vague. Are you looking for a shop to do the masking & plating (you did not allow us to release your email address to potential vendors and we can't let vendors post free ads here or we'd drown in spam) or are you looking for instruction to how to mask it. It's possible that some kind of caps could mask the ends, but you'll more likely need to tape and/or lacquer the areas. Hopefully you realize that you will also need an internal anode to accomplish this. Good luck, and please get back to us with photos and details and your contact info.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 2, 2019

A. You'll be using an internal anode. It may be possible to mask part of the anode to limit the area plates.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

July 2019

Q. Apologies for not giving in details,

Cylinder is of 67 Inch in Over all length, so we won't be able to mask by tape or Lacquer by hand, and we need chrome coating on middle portion for a certain length, and we need to mask the rest on internal area from chrome plating,

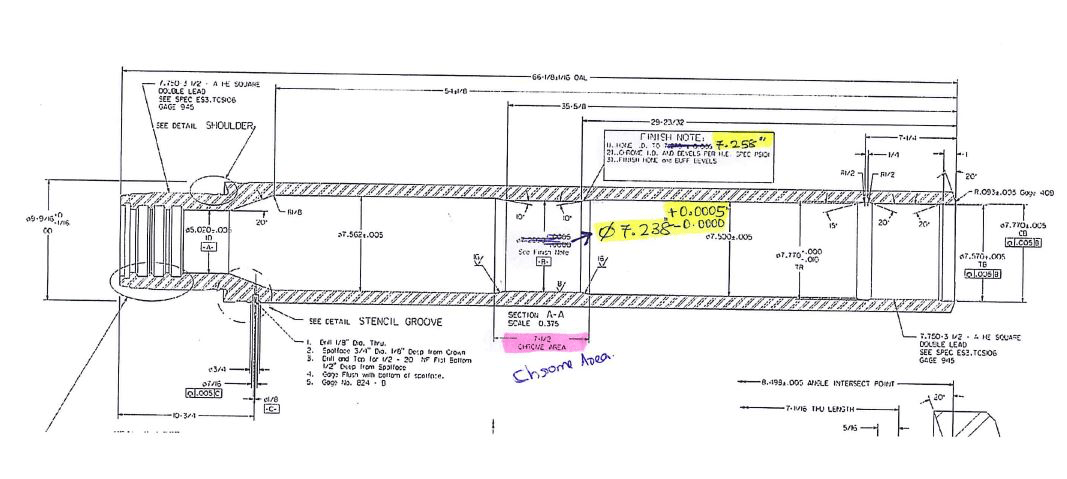

I have given Drawing as below:

oil field supply Center - Dubai, UAE

July 3, 2019

----

Ed. note: This drawing is too low resolution to read accurately, but it looks like the area requiring chrome plating is about 7-1/2" long on an I.D. of about 7-1/4" in roughly the middle of a 67" long hollow roller/shaft.

July 5, 2019

A. If the chrome plating has to be controlled to a precise area, you could mask both ends with snug fitting plastic tubing.

If there is allowance for chrome to extend some distance beyond the specified area, you can use a masked internal anode.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

November 4, 2019

A.

1- use a lead masking tape from both side area to be plated

2- be sure to mask any critical areas so seeping acid won't damage areas not required to be plated

3- a good contact and a support to center the inside anode

4- paper mask for area to be plated

5- dip shaft in masking wax tank couple times to have proper wax thickness

6- remove paper mask and clean area to be plated

7- proceed etching, and plating. Good luck.

Khair Shishani

aircraft maintenance - Al Ain, UAE

![]() Well said Mr Jeffery Holmes and Mr Khair Shishani!!

Well said Mr Jeffery Holmes and Mr Khair Shishani!!

Khozem Vahaanwala

Saify Ind

Bengaluru, India

December 6, 2019

finishing.com is possible thanks to our supporting advertisers, including:

Q, A, or Comment on THIS thread -or- Start a NEW Thread