Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Carburetor Shaft Coatings, Sticky Linkage, Worn Needles, & Internals

Quickstart:

We have many threads about restoring a nice goldish finish to carburetor bodies (search the site using terms like 'chromate' or 'zinc plate' plus 'cqrburetor')

This thread is about everything else, including shafts, linkage, and needle coatings.

Re-plating of shafts

I restore Carburetors for antique cars My problem is re-plating the steel linkage parts. Some of the early 1900s were copper plated but most of the pot metal ones had zinc or cad plating. Most of these parts are small, less than two inches in length, so I think an electroless process is what I need. The reason for plating is to prevent rust.

I would appreciate suggestions and recommendations

THANK YOU

Bob Potterrestorer - Alamogordo New Mexixo

1998

A. Hi Bob,

You should not do cadmium plating; it is a cumulative poison, forbidden in some countries and used only for indispensable life-critical applications in others. Use zinc plating instead.

But I don't think you need an electroless substitute--small quantities of small parts can simply be 'wired' (hung from a small plating rack, or tied in place with light gauge copper wire), or possibly barrel plated.

Plating is highly regulated if you are a business rather than a hobbyist. You might consider retaining the services of a plating jobshop ... but zinc plating is not beyond the reach of a dedicated hobbyist. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

--

Electroplating brass onto carb needles?

Q. Hi Everyone,

I want to thicken the thin, brass fuel metering needles on my Stromberg carburetors by electroplating some brass (or copper) onto them. I need to increase the diameter by about .1 mm. The needles are about 2 mm thick at the moment. Does anyone know if this is possible (or any other way to make them a bit thicker?

Appreciate any help.

Warren HardingAuckland, New Zealand

1998

A. Hi,

I owned and operated a 1965 Sunbeam Alpine, and a 1964 Triumph TR4, so I used to be an enthusiast who was constantly under these cars. But they were fun when they would run, I was seventeen, you know the drill. I think one had SU's and the other had Strombergs. What I really wanted was a Sunbeam Tiger, under whose bonnet some genius had stuffed a Ford 289.

Here is a way to add copper that might work.

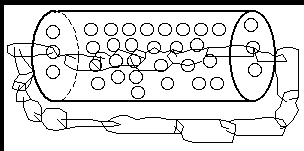

Most platers should have a few of these homemade devices around, but in case they don't, here is a (very) rough sketch:

The squiggly thing is my rendition of a chain. The contraption is a plastic tube with holes drilled into it, capped on both ends with the chain running through the inside and outside. There are many variations of this cell, you can line the inside with fine screen for tiny parts, different ways to make the caps, electrical contact could be bolts through the body, etc.

Stick the pins inside, close it up, and take it to a barrel plater, Platers have these around to test plate a small amount of parts in their big barrels. They put the sample parts into it, and toss it into a barrel filled with the usual run, (see Mr. Frank R. Zemo's excellent Introduction to Barrel Plating, of Polaris Plating Co. for photos of a barrel plating operation).

Make sure that the diameter of the plating cell is not so big that the pins can get tangled. You may also need to put some media inside to help plate smoothly. I would suggest some samples before you try your metering pins.

I would say that a few dozen donuts should cover the plater's cost, but you would have to find out what they get in your area. Maybe a tuneup or a brake job?

Tom Pullizzi

Falls Township, Pennsylvania

A. Don't try to plate the needles they are tapered to cope with your fuel mixture; incorrect coating could cause damage costly damage contact Wilson Carburetors Queensberry st Carlton Vic Australia. Give them your vehicle details with c/o, h/c emission reading and they will be able to supply you with the metering needles you require.

David walkercarburetors - Australia

|

|

Hi, I am studying at chem dept ITB and want to know about the brass electroplating. Is it possible to get colour brass plate ? Please give me more information about that . Thank you very much. Yeni Astuti1999 Ed. note: Brass is an alloy of copper and zinc. Alloy plating is not for students or beginners because, for electrochemical reasons, they will not be able to get any of the zinc to deposit when there is any copper in the solution. We have many threads about brass plating, and the best starting point is probably thread 0865. Good luck. |

Coating of Linkage shafts

Q. My current automotive projects involve the complete rework of Carter Thermoquad carburetors. The throttle & choke linkage shafts are coated with an olive-drab green colored coating. This coating is very slick and waxy which makes me believe it is teflon-type of material with a polymer binder. I would like to re-apply this coating to restore the low-friction characteristics that these shafts originally had. I have read a letter which references a gun finish called Green-X which sounds very close to what I need. Any information on what this coating may be, and a source for the coating, would be greatly appreciated!

Nohr Tillman- Royal Oak, Michigan, USA

1999

A. I believe that the coating you seek is Acheson Colloids [Port Huron, MI] Emralon. I have an old brochure that shows carb parts, painted with the stuff. It is indeed a PTFE dry film lubricant in a phenolic or epoxy resin. Mike

Michel Moninger- Sarasota, Florida

Zinc/aluminum alloy treatment HELP needed:

Q. Need information. My carburetor internal parts are made of the same material, zinc/aluminum maybe magnesium alloy. The throttle valve slides inside the body wearing-out frequently. Question: Is there a coating/treatment that I can apply that would change the characteristics and make the two surfaces dissimilar enough to be able to wear longer? Something like Ospho [adv: Ospho on eBay or Amazon [affil links] or other caustic treatment and then maybe polishing to improve lubricity. Is there such a procedure that I can try?

Thanks so much for your help

Pat

P.R.K [last name deleted for privacy by Editor]- Gainesville, Florida

2000

A. If it were my part, I would machine it (undersize/oversize) and put 0.001 ± of electroless nickel. No post treatment is required if you spec out your machining tolerance and plating tolerance to a combined amount that you can live with.

Plate the easiest part to plate. This costs a little more, but is fantastic for your stated needs. It's hard, corrosion resistant and is naturally slippery.

James Watts- Navarre, Florida

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Tin and cadmium plating on carburetor linkage

I am rebuilding some old carburetors and want to tin plate or cadmium plate some linkage. Can anyone tell me how to do this myself or is the process too complicated?

Thanks,

Burke Bowman- San Antonio, Texas

2003

A. You will not want to go with cadmium plating these days as it's a bio-accumulative poison similar to lead and mercury, and it's use has been drastically curtailed in the last decade. Tin plating is okay. And Eastwood offers a tin-zinc plating solution which might be ideal.

However, personally, I'd suggest you take them to a plating shop if you want the plating done right. Conceptually, zinc plating is dead easy-- see our "How Plating Works", complete with instructions for young schoolchildren to do it. But demonstrating a concept and doing robust plating are different things. According to Jack Dini, former metallurgy and metal finishing section head at Lawrence Livermore National Laboratories, writing in Electrodeposition--The Materials Science of Coatings & Substrates:.

Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi, I am a semi-retired automotive restorer (grew up fixing, or trying to fix, whatever broke before paying money for a new one) working on a 1950 single barrel carburetor that has two brass shafts inserted into one of two metal housings. One shaft is designed to pivot within a cast iron base and the other pivots within a "base metal", more fragile metal casting.

The entire carburetor had been left outside for some time and neither shaft moves at all. I started out trying PB Blaster penetrating fluid, sand blasted the parts clean, put them in a commercial parts cleaning machine at 175 degrees, submerged them for 10 days in "Sea-Foam" liquid penetrating fluid (a gasoline additive) with no results to date.

My next try is to use a heat gun

⇦ this on

eBay or

Amazon [affil links] to get the temperature up to the higher 100s or to put them in a freezer (I don't think I want to tell my wife about that just yet).

The carburetor is in great shape other than the shafts are frozen, am I resigned to drilling them out and then making new shafts?

Thank you for your help,

Ted

Hobbist car restorer - re-doing 1950 Chevy car - Sandy, Utah, United States

May 17, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread