Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Silver plating Musical instruments

Quickstart (no readers left behind):

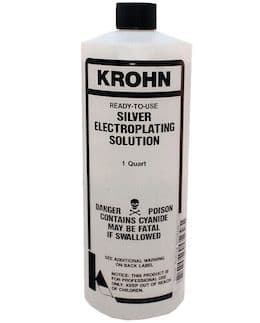

Nearly all silver plating is done from cyanide solutions, which are deadly poison unsuitable for home/hobbyist use. If a hobbyist wants to experiment with silver plating, there are some cyanide-free approaches, but musical instruments are very difficult to electroplate for several reasons: large size, need for careful masking of internals & moving parts, possible tone changes, etc. -- so to add to the difficulty by using inferior cyanide-free solutions presents a huge challenge.

We urge hobbyists who wish to try silver plating to practice on simpler items and scrap rather than risking damaging a precious musical instrument.

But persevering readers will find most of what they wish to know in this thread.

[editor appended this entry to this thread which already addresses it in lieu of spawning a duplicative thread]

Q. Hi everyone,

I could use some insight. I work in musical instrument manufacturing and we are looking for ways to make the horn airtight for plating to avoid the inadvertent plating of the inside of the horn. We have made solid valve caps, and lead pipe and bell plugs and have been using stick lanolin on the valve slides/main tuning slide to prevent the slides from being plated in place. One of our platers is asking us to not use the lanolin to spare their tank from the lanolin leaching out. We have noticed that where the slides abut, there is some cloudiness in the final result. We experimented with Stop Off, but it's not creating a seal. Does anyone have any advice on how we can go about keeping solution from getting into the horn, while also being something that won't leach into solution. Thank you in advance.

Shipping Manager - Holliston, Massachusetts

February 10, 2025

⇩ Related postings, oldest first ⇩

Q. Not sure I'm asking this question in the right place, but where might I find information about learning to silver plate brass musical instruments? Such as the technical process used, training programs, professional organizations. Thanks in advance.

sometimes on

AbeBooks or Amazon

(affil links)

free pdf is currently available from academia.edu

- New Hope, Minnesota, USA

2002

A. The process involves many steps, from polishing & buffing, through cleaning and acid activation, silver striking, silver plating, and post treatments, and involves extremely poisonous cyanide solutions. The National Association for Surface Finishing is the lead technical association, and the easiest place to start learning (in addition to this forum) would be with a copy of the Metal Finishing Guidebook.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have been plating iron and copper successfully using a simple ammonium chloride bath. I recently have developed a need for silver plating and wanted to know if a similar bath would be feasible? Or do I have to go with a commercially prepared bath? I want to plate between .0005" and .001" and want to plate from the anode.

Thanks for any help,

Kyle Olson- Lincoln, Nebraska, USA

2003

A. In order to be able to electroplate a material out of solution, you have to first be able to dissolve it into solution. While iron chloride and copper chloride are soluble salts, silver chloride is not, and will precipitate immediately, so you cannot plate from that. Yes, silver chloride is soluble in ammonia, but any time you are fooling with silver & ammonia

⇦ this on

eBay or

Amazon [affil links] together you are in danger of creating silver fulminates which are incredibly powerful and volatile motion-sensitive explosives -- a speck of which can blow up you and your lab. Personally, I wouldn't even attempt mixing silver and ammonium chloride.

Please use a commercially available solution for silver plating ... good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello. I am a University Graduate student. I have been plating copper photogravure printing plates with Iron using a one pound to one gallon mixture of Ammonium Chloride to Water. I also have been electroforming organic objects with Copper using the same electrolyte solution. (Only the same formula not the same solution bath to plate different metals.) I would like to plate silver onto copper for making photo plates as this is a mandatory step. Would I be able to plate silver using this same solution formula? I will be plating between .0005" and .001" of silver onto my polished copper plates and then polishing the silver surface. I am also plating from the anode for both iron and copper and would like to continue to do so for silver. If I am not able to silver plate using this formula can anyone suggest an alternate formula or must I use a commercially prepared formula? If a commercial formula is mandatory and it is within the policy of the website is there a recommendation as to what will meet my needs? If this will help answer the question I am plating iron to copper in a 30 gallon tank, copper in a sixty gallon tank, and will be making a 2 gallon tank to plate silver. I will be using copper plates that are any where form 4"x5" to 6.5"x8.5". All copper is 32 lb copper. I hope that I sufficiently covered my situation, I reissued this question with more information.

Thank you,

Kyle Olson [returning]University of Nebraksa Lincoln - Lincoln, Nebraska, USA

2003

A. Thanks Kyle. I think the most practical silver plating baths are cyanide based with organic and inorganic brighteners. Cyanide has been the process of choice for 95% of silver plating for over a hundred years, but whether your university will let you use that deadly poison, I don't know.

Non-cyanide solutions are commercially available from companies like EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser], but we can't recommend one over another ( huh? why?), although suppliers may be unwilling to ship to students.

You can do a patent search which will reveal expired patents if you do not wish to purchase a commercial formulation from a plating supply house.

Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Russian bath recipe:

15-90 gm silver pyrophosphate,

100-350 gm potassium pyrophosphate ⇦ this on

eBay or

Amazon [affil links]

,

20-145 ammonium carbonate ⇦ this on

eBay or

Amazon [affil links]

(not chloride!),

temp. 18 °C,

0,5-12 A/dm2.

From Russian book "Galvanotehnika blagorodnih I redkih metalov/Leningrad" 1970 (electroplating of precious and rare metals)

- Cerovski vrh Croatia

![]() Thank you for the informative response. I will do as you suggest and not try this. This does leave me without a plating solution. Do you have a suggestion of a standard, non-proprietary plating formula? Thank you again. Kyle Olson (As a curiosity, I thought fulminates were stable in solution and gained their notoriously explosive nature once in solid form. I thought that meant dry but if they precipitate out and are thus solid that would meet the criteria for "not in solution." Anyway just my curious naivete and not any suggestion of trying this by any means.)

Thank you for the informative response. I will do as you suggest and not try this. This does leave me without a plating solution. Do you have a suggestion of a standard, non-proprietary plating formula? Thank you again. Kyle Olson (As a curiosity, I thought fulminates were stable in solution and gained their notoriously explosive nature once in solid form. I thought that meant dry but if they precipitate out and are thus solid that would meet the criteria for "not in solution." Anyway just my curious naivete and not any suggestion of trying this by any means.)

University of Nebraska-Lincoln - Nebraska, USA

2003

A. Technic and at least one other company makes a silver plating solution that is cyanide free. You will need a silver strike and I do not know if there are any that are free of cyanide. A silver anode will be necessary for most applications. That will depend on its use. Brush plating is an option, but a workable setup would cost several hundred dollars and its quality is extremely operator sensitive.

James Watts- Navarre, Florida

A. Other suppliers include EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser] and Zinex. There are possibly others.

Luck & Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello again,

I posted a question this summer about the possibility of plating silver with an ammonium chloride bath. (I am attempting to plate silver onto polished copper. I then fume the plate over iodine and bromine. At this point the plate is sensitive to a certain range of light. An exposure is made on the plate and then a development and post development fix the plate. After outsourcing the silver plating we are attempting to do it in house here at the university because we already perform some simple plating of iron and electroforming of copper. )

The response that you gave was very helpful and I again wanted to thank you for the advice. I have since taken your advice and mixed the suggested double cyanide bath. The formula was an older one, as you also told me that is what I would probably be able to find. I have, of course, been following good chemical safety, fume hood at all times, and I enlisted the aid of our chemistry department in working out the formulas for monitoring the silver and free cyanide content of my solution. My question concerns my brightener. My formula suggests .0001 oz/gal of carbon disulfide. It also suggests using "turkey red oil" (or sulphated castor oil to be correct) to "stabilize" the carbon disulfide.

Before adding either of these I wanted to consult experienced experts on whether or not you could suggest

1) a superior brightener either a) proprietary or b) the correct formula/proportions for a non-proprietary additive(s)

2) if you can't lead me to a better brightener, at what ratio should I add the turkey red oil ? my formula is not specific, only that it may be successfully used to stabilize the disulfide. If you suggest a proprietary brightener would you be so kind as to inform me of the company or manufacturer of the product?

Thanks a lot for your past insights and for your time and help with this question.

Kyle Olson [returning]student - Lincoln, Nebraska, USA

A. Kyle,

I suggest that you try to make daguerreotypes without the aid of a brightener in the silver plating solution.

Mike Robinsondaguerreotypist- Toronto, Ontario, Canada

Q. For making the silver plating solution I am using:

- pure silver anode

- sodium cyanide

It's the correct formula?

Choo Yik Hean- Malaysia

2004

Ed. note: Unless you are an experienced chemical process supplier, you don't "make" silver plating solution, you buy it.

A. For those who want to plate silver on brass or copper the best solution is to use a cyanide silver bath by using a silver nitrate solution and transferring it to silver chloride, which is a white crystal non-soluble in water, then transferring it to silver cyanide by adding a pure free potassium cyanide to the Ag chloride.

Elias Haddad- Beirut, Lebanon

2004

Ed. note: Thanks Elias! The only thing we would add is a note that preparing a cyanide-based silver plating solution is for experienced chemists in properly equipped labs, not for amateurs :-)

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I'm a professional musical instrument repairer specialised in wind instruments, and I read the whole of the input into your site to try to find out more about electroplating. I think the overall message about the dangers involved and in particular the lifetime responsibility for the dangerous products used is very well put. My question is really what is the metal normally used for plating what we call "silver" instruments? Is it really silver? And does it therefore involve really dangerous liquids? Does anyone know of a company doing a musical instrument plating service in the States, in Britain or in Europe? I am thinking seriously of setting up a full scale service myself, applying maximum safety conditions and proper waste disposal. Apart from the advice you may well give me: "DON'T DO IT!" which of the many books would be the best to start with? Thanks in advance - and thanks for the very serious way you treat the problem on your site.

Keith BraithwaiteMusical instrument repairer - La Capelle, Picardy, France

2004

A. Hi, Keith.

The finishes that look like silver plating are in all probability actually silver plating. Silver is very "white", usually slightly milky compared to other plated "white" metals like nickel (slightly yellow), zinc (not fully bright), cadmium (inappropriate), chromium (blue-ish), or rhodium (dazzlingly bright, too bright).

Almost all practical silver plating is done from silver cyanide plating baths, and cyanide is a deadly poison. You can absolutely do electroplating yourself, but it really should be in a dedicated shop, not in a kitchen, basement, or residential garage. You should be trained in hazardous materials management, and you should be registered and permitted by the authorities who regulate plating activity in your locale.

As you probably know, silver tarnishes. To keep the problem manageable, in addition to silver plating you may want some sort of anti-tarnish post treatment--whether it be a chromate dip (probably not a good idea for musical instruments), rhodium plating, an organic tarnish preventer, a clearcoat, or whatever. You will probably need buffing capability and plating pre treatments as well.

If I was restricted to one single book, I think I'd pick the Metal Finishing Guidebook and Directory, but the Electroplating Engineering Handbook is excellent ⇨

and you'll find several other choices listed on our "must-have" booklist.

Good luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Dear Keith!

Today exist several cyanide-free silver plating proprietary products (3 on USA market).I am sure that somebody in France produces or sells that type of plating bath. You can even make yourself that type of bath (several good formulations exist, some of them are known even in 19th century/ferrocyanide bath and sulphite based bath). I have worked with ferrocyanide based bath over ten years and I can only say that it is simple to prepare and safe and if you work carefully results are very good.

Good luck!

Goran Budija- Cerovski vrh Croatia

Q. Thanks for getting back to me Ted Mooney and Goran Budija. I'd like to know more about these safer products, Goran. So a ferrocyanide based bath can be fairly easily prepared and is safe to use? I'd like to hear more about that. Any literature on the subject would be interesting too. Thanks very much

Keith Braithwaite [returning]Instrument repairs - Picardy, France

2004

A. Ferrocyanide silver plating bath:

200 gm potassium ferrocyanide

⇦ this on

eBay

or

Amazon [affil links]

20 gm potassium carbonate ⇦ this on

eBay or

Amazon [affil links]

40 gm siver chloride ⇦ this on

eBay or

Amazon [affil links]

1 lit water

stainless steel anode ⇦ this on

eBay or

Amazon [affil links]

, 60-80 °C temp.

Dissolve ferrocyanide in boiling water, when it is dissolved add carbonate and when it is dissolved add silver chloride.Boil 1,5-2 hours, filter when cold. This bath can be used for plating and electro forming. For bright plating you can add up to 0,03 gm/lit sodium thiosulphate ⇦ this on eBay or Amazon [affil links] . Keep it in dark bottle. Never mix bath and strong acids! -- according to V.I.Semerjok, from Ukrainian book "Galvanotehnika blagorodnih I redkih metalov" (Electroplating of precious and rare metals)

Goran Budija- Cerovski vrh Croatia

![]() Many thanks for the formula - once I've finished reading the book and seen more or less how to approach the task from a safety point of view I'll get down to trying it out.

Many thanks for the formula - once I've finished reading the book and seen more or less how to approach the task from a safety point of view I'll get down to trying it out.

Thanks again

Keith

Keith Braithwaite [returning]Instrument repairs - France

Q. I am a woodwind repair technician with no experience plating instruments. I found a company that tells me there is no cyanide in their plating solutions and no concern with respect to toxicity.

Am I being naive or is it possible that they have a truly safe product to use? What do you think? Thanks?

Alan Lefkowitz- New York

2004

A. Hi, Alan. I'm confident that it is cyanide-free. I'm less confident that the color is "spot on" because the largest manufacturer of cyanide-free silver plating solutions markets them for electronic use, saying the color isn't quite perfect for decorative use. But if you are doing a few random items, rather than thousands which must exactly match, it's probably good enough.

Remember though, that although cyanide is dangerous, cyanide-free does not quite mean "no concern with respect to toxicity" and "truly safe". Best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Refinishing a King Trumpet

Q. Hi I would love to refinish my trumpet. It is a B-flat King. I got it off eBay for $140.00. This Trumpet is in excellent shape. There are no dents. Most of the finish fell off though. I want to get it refinished silver or gold but but at an inexpensive price. If it is possible I would like to refinish the trumpet at home. People in my Band are making fun of me and I can't blame them. (even though it does get annoying)

Thank You

- Florham Park, New Jersey

2007

A. You can go to an automotive or hardware store and buy a can of brass metallic spray paint and spray it yourself.

Sheldon Taylor

supply chain electronics

Wake Forest, North Carolina

A. Real silver plating is absolutely not a home project, especially on something as large as a trumpet. For a quality job, send it to a professional. PS, it will cost less to have a professional high quality silver plate than it would cost to set up the silver tank at home. Then you would have a disposal and a hazard in your garage.

James Watts- Navarre, Florida

Q. I've been working with a plater that silver plates trumpets. He says that he doesn't like to plug the holes of the trumpets because the horns tend to float if air is left in them. I do not want to have plating on the inside of the horn because I think it affects how the horn plays.

He also does not want to risk polluting his solution by filling the horn with water or some other fluid.

I'm suggesting that he plug up all ports of the horn when it is full of plating solution before the plating begins. My question is this: If the horn is under the solution and the openings are plugged up, how much if any of the plating will end up on the inside of the horn from the solution trapped inside?

Buyer - Charlotte, North Carolina, USA

May 31, 2009

A. I don't think filling the horn with deionized (or better yet, distilled) water, then plugging it off, is going to hurt his tanks. You might get a little "spit" in there...Plugging the holes will work, if enough weight is attached

George Brackett III- Maine

A. I am playing my silver plated trumpet at church tonight. When I was a coop student at Georgia Tech, I plated my own horn in the plating shop I worked in. The horn did not float when I tied an inert weight to hold it down.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

!! And here I am fooling around with silver spoons, a power supply, and some type of salts with fruit acids and saccharin and whatnot (for stomach problems) and a few pearls of plumbing cleaner soda ... and plating copper with silver from a spoon. Hehe ... oh, and almost forgot, a couple of cigarette ash taps for the hell of it into the mix; first I reinvented Coca Cola (looks like Silver sulfide) and there is some black version of calcium deposit on one spoon, I used two spoons at first to make the famous soft drink, but then I put the piece of cleaned copper plate back in as anode and it became silvery.

Voltage, I used like 8 V for a while, then 24 V, then 10 V and whatever. I think now it runs at 8V again, lol

Regarding Ag2S, I am going to try an aluminium plate and either nitric acid or baking soda sometime; maybe it makes a silver colloid or something, but that can be drawn out with silver electrodes or something I suppose.

Hehe, I am just fooling around with this out of curiosity.

- Enplass, Nordvest, Norway

March 2, 2011

Q. What is the "silver" plate used on modern musical instruments? In the old days regular silver plating was used. New trumpets are advertised as silver, but are much more durable than before. They also don't tarnish like real silver.

Dwight JohnsonHobbyist - instrument repair - Wheaton, Illinois USA

August 5, 2011

Hi, Dwight.

It's probably real silver plating, as always, but with a higher technology and more-effective clear coat replacing the traditional lacquer or a flash of rhodium plating on top. If you look at today's auto headlights, nearly all are the plastics of yesterday, but they no longer scratch and craze because of super-hard radiation-cured clear coats. I am not involved in musical instrument manufacturing, but suspect that similar coatings are used.

I wouldn't call the bright instruments better, it's a matter of taste. An outstanding local saxophone player's instrument looks almost brown with age rather than brassy.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Using silver ring as anode, and worn silver plated necklace as cathode, What solutions would work?

Greg Alton- Evansville, Indiana, U.S.A.

April 5, 2013

A. Hi Greg. Potassium silver cyanide or sodium silver cyanide is certainly the most popular and robust. But these are horribly toxic chemicals. Please get to a library for a plating text -- the formula has been the same for well over a hundred years, but at the least you should read about the most obvious hazards like hydrogen cyanide gas. You also should recognize that bright, robust, functional electroplating is a different thing from the plating that is demonstrated in high school chemistry lab. Using an old ring as your anode instead of high purity anodes will probably prove problematic.

You can buy a non-cyanide process with less toxic but proprietary complexers from suppliers like Zinex or EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser], and probably from hobby plating suppliers.. Make sure whatever you buy isn't cyanide based. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. This thread is very helpful. Thank you.

I'm new to plating, educating myself. I'm hoping some posters might chime in to help me. I'm interested in brush plating/pen plating areas of worn-thru plating on a tuba (very large piece). I'm not sure if the mostly intact plating is silver or nickel, but the underlying metal is brass.

Questions:

Does the large size of the piece mean I'l need more amperage?

Do I have the following steps right?

Step 1: Polish worn spots to a mirror finish.

Step 2: Use stainless anode wrapped in a brush/pad for electrocleaning with an alkaline solution, yes?

What alkaline electrocleaning solution do you suggest?

How long?

Step 3: Rinse area to be brush plated with distilled water.

Step 4: Short bath in acid dip.

What acid dip solution do you suggest?

Step 5: Rinse area to be brush plated with distilled water.

Step 6: Brush plate worn-thru areas with silver (or nickel) anode wrapped in a plating gauze soaked in silver (or nickel) pen plating solution.

What pen plating solution and voltage/amperage settings do you suggest?

Most importantly: What do I have all wrong, and/or what am I missing?

Thank you for any suggestions or corrections.

- Columbus, Ohio

November 1, 2020

A. Hi Riccardo. Somehow you must find out whether you have nickel plating or silver plating, as they will be quite different, silver requires stripping of the lacquer, and nickel requiring activation with Wood's Nickel after polishing. Your steps seem okay, but the step I'd be most concerned about is deciding what to plate. You should acquire some plating experience plating scrap & simpler pieces before you try working on something large, useful, and valuable like your tuba.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread