-----

Trouble with rose gold plating

Q. My Rose plating in oxidation. So I want formula for Rose gold. Sir help me.

Md Sheik azaruddimRose plating - Kolkata, India

July 2, 2021

by Reid & Goldie

-- hard to find & expensive; if you see a copy cheap, act fast!

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi. Your question is a bit brief to understand, but yes, rose gold is quite prone to oxidizing because it contains copper. If you can find a copy of Reid & Goldie ==>

in a local or university library it will provide a good education on the subject.

You can follow the instructions on this page for your rose gold, but two points:

• Most professionals do not attempt to formulate their own plating solutions, as explained by Geoff below.

• Because of the copper content in rose gold plating, you may find adding a clearcoat to be a more productive approach than trying to find a rose gold plating solution that doesn't discolor.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

July 2021

September 26, 2021

Q. My Rose gold plating is not successful. Short time to oxidation. Please help me.

Employee - West Bengal singur [returning]

Q. Hi,

I am looking to Rose Gold Vermeil tank Plate 2.5 microns of Rose Gold, over a Sterling Silver base, with a Palladium barrier layer between base and Gold plating.

It was previously suggested to 2.5 micron Gold Plate, then use a gilding layer for colour.

I was wondering if this Rose Gold gilding layer would wear, and the gold yellow gold colour would show through?

Thanks

- Kent, England

September 15, 2021

⇩ Related postings, oldest first ⇩

Imitation rose gold

Q. I'm in need of a formula for imitation rose gold. Can anyone provide one or refer me to someone who can?

Jay Alford- Hanahan, South Carolina

1999

(to help readers better understand the Q&A's)

Despite the 'global village', people from different areas still use different English words & phrases.

What we in he USA usually call "costume jewelry" (jewelry which is more affordable than "karat gold jewelry" or 'fine gold jewelry") because the gold is only plated onto the surface), people in other areas call "imitation gold".

So "imitation gold jewelry" doesn't necessarily mean jewelry which contains no actual gold; it can also mean 'costume jewelry', which is more affordable than karat gold due to the gold being only on the surface.

A. Could not resist. I believe the only imitation rose gold is called copper :-)

and it has been used (not by my Company) in the past.

Bob Lynch

plating company - Sydney, Australia

1999

A. You can use approximately 1/5 part copper sodium cyanide CuNaCn in your gold plating bath by the percentage of the gold potassium cyanide.

I forget if you like to use a green color in your gold plating you can use a part of cyanide potassium silver AgKaCn in your bath. You must try these recipes in a cell first before you try it in the bath because the recipe is very old. If you don't have a gold bath you can experiment with your brass bath with the current and the contents.

Anders Sundman

4th Generation Surface Engineering

Consultant - Arvika,

Sweden

Trouble with rose gold plating -- the right color will tarnish

Q. Currently I am working on projects that require a Rose gold finish. It is very hard to get the color right and keep it from staining or tarnishing. My amperage is probably off as well, and need to know the correct amperage to set on.

If you can help me with this problem please write me.

Thanks,

Johnny gutierreza plating company- San Antonio, Texas

2003

A. Dear Mr. Gutierrez,

I have not found an electroplating process that can produce a rose gold finish which is tarnish free, especially if you are trying to match the color of a cast rose gold which has more of a copper color than gold. It appears that metals deposit as a dispersion and not a true solid solution as in the cast version. This causes the copper at the surface to oxidize in a normal manner. Increasing the gold content can remedy the problem, but you may not get the desired color.

Good luck and if you solve your problem please let us know.

Michael Wisniewski- Chatsworth, California, USA

2003

by Reid & Goldie

-- hard to find & expensive; if you see a copy cheap, act fast!

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi gentlemen. I am not a gold plater, and can only respond from book knowledge and regarding what has been posted on this site over many years. But Reid & Goldie .

seem to imply that the best approach to color gold is to do heavy gold plating from a standard bath and top it off with 0.5µm of color gilding, and they offer the solution composition and operating parameters for an 18 ct pale pink bath and a deep pink-red bath.

Readers have noted (letter 52562 is a good starting point) that the reddish color comes from its high copper content, so you are limited in preventing tarnish.

How about a thin electrophoretic or UV cured lacquer on top of the pink gold?

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I live in Thailand. Where I live I cannot get gold plated findings for my jewelry. I have to make two pieces for the Princess of Chiang Mai, and one for Princess Somsomali of the Thai Royal family. I would like to find a gold plating system that uses rose gold, white gold, and yellow gold.

I really need help fast, due to the foundation that I work with, they are wanting the profits for Northern Children's home for the Blind, and other charities for children.

If you can help me I will greatly appreciate it.

I did check Medallion but no information on different gold and no silver.

Your response is greatly appreciated.

product designer/retired - Chiang Mai, Thailand

April 8, 2010

A. Pink, green, yellow, white, rose, red gold are made by adding particular alloys into .995 (23.88k) pure gold to make 9, 10, 14, 18, 22k gold Jewellery. You should plate this Jewellery only those colour in which you cast the Jewellery for better finishing.

Bhupesh Mulikjewellery - Mumbai, India

April 24, 2010

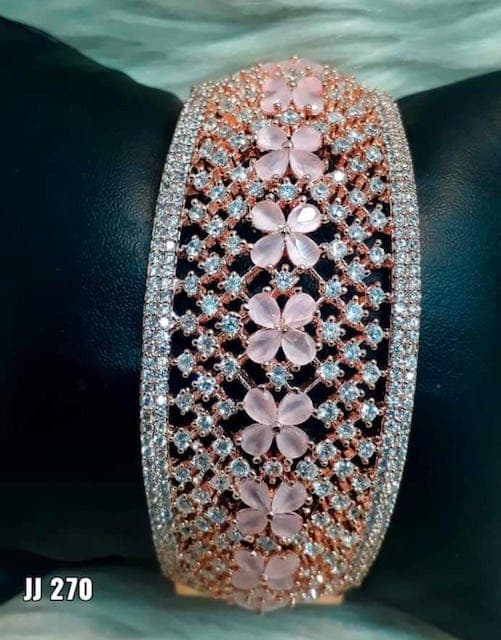

Need Rose Gold Plating on SS Watch (Case and Bracelet)

July 28, 2011I have a stainless steel Omega watch from the 1970's. Condition is pretty good without major dents or scratches. I would like the case and bracelet to be plated in Rose Gold. I am seeking a high quality finish, maybe even a brushed rose gold if that exists, that would last at least 10 years. At least 10 microns?? I have will defer to the experts.

Local shops (NYC) are preferred, but definitely don't mind sending away for quality.

Thanks!

Paul H

horology - New York, New York, USA

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

June 5, 2014

Q. Hi,

I am a jeweller wanting to Gold Plate some items of jewellery myself in my studio. Lots of solutions exist for tank/immersion plating gold, but only one or two for Rose Gold. I have come across lots of Gilding solutions, but these do not plate the thickness I require. Lots of mixes exist for Rose Gold but these are only suitable for Brush Plating.

I am looking for 2 microns thickness of Rose Gold, plated over Sterling Silver pendants via immersion plating... is this possible? Or is there a specific reason this would not work? I realise I will need heat and agitation and specific equipment.

I have found some solutions in the USA but none that will ship to the United Kingdom for security reasons.

I would like to do it myself in my studio as I am a very small jeweller and would like to keep costs down. Lots of other jewellers are Rose Gold plating themselves, so a solution must exist, I just need to find it! lol.

Someone also suggested plating my silver pendants with a 2 micron layer of Yellow Gold plating and then a flash plating of Rose Gold over the top... would this not just wear off over time and the yellow show through??

Thanks!

Jewellery Designer Maker - Maidstone, Kent, United Kingdom

June 2014

A. Hi Hayleigh. We appended your interesting inquiry to a thread which already discusses several aspects of it, but taking them up in the order that you raise them ...

Reid & Goldie seem to suggest that you should plate the bulk of your 2 µm requirement from a more robust standard plating bath, applying only about the final 0.5µm from the more temperamental rose gilding solution. If you can't find tank plating solutions, but have found suitable brush plating solution, maybe that's a better approach.

Immersion plating to anywhere near that thickness is not possible. The 'battery' that drives immersion plating is the difference in electrochemical potential between the substrate and the plating. As soon as the substrate is covered, the battery is dead.

Rather than 2 microns of gold and a "flash" of rose gold that wears off quickly, try the compromise I mentioned that Reid & Goldie suggest.

Rev'd June 10th: I had somewhat misread Reid & Goldie. They suggest that before the 1/2 micron pale pink gilding solution (2 g/l gold, 2 g/l copper, .05 g/l silver), you plate 1-1/2 microns from an 18 carat pink plating solution (4 g/l gold, 2 g/l copper, 2 g/l zinc), not yellow gold as I probably implied.

Best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

June 9, 2014

Q. Hi Ted,

Thank you so much for your help! I think I am getting my terms mixed up -- when I say immersion plating I mean tank electroplating ... I think. I will be using a kit rather like this: www.goldn.co.uk/gold-tank-plating-kit/

Will a solution like this:

www.gold-plating-kits.co.uk//100ml-rose-gold-plating-solution.html

work in the above kit to give me a thick layer of Rose Gold plating? Roughly 2 microns?

I have been told if I am using a liquid solution, I will need at least 5 grams of gold per litre in the solution, is this correct?

Would Red Gold plating salts be a better way of plating? Such as this --

www.cooksongold.com/Jewellery-Tools/18ct-Red-Gold-Salts---2-Litre------Un3077-Tnt-prcode-998-134

I have also been told a solution by Jentner JE216 may work -- which of the above would be the best?

I will be plating sterling silver jewellery and as I am selling it in Europe pre-nickel plating before the gold is illegal so not an option, is there a suitable alternative?

For the liquid solutions I have found a tank plating calculator online which allows you to calculate how long to leave in the "tank" (Pseudo-tank-beaker-thing) for the thickness required.

Thanks,

Hannah

Jewellery Designer Maker - Maidstone, Kent, United Kingdom

A. Hi again. Sorry I misunderstood what you intended by "immersion plating".

Generally, high concentrations are used for the main plating solution and low concentrations for the final color gilding. I don't know the capability of those particular proprietary gold plating/gilding solutions, but we do not comment on specific brands or sources in the forum anyway (why?)

Most plating professionals recommend purchasing proprietary plating processes rather than attempting to formulate your own. And once you take that path, you need to follow the technical data sheet provided by the vendor. It is problematical to half-follow the vendor's instructions and half-follow someone else's. "Too many cooks ..." or something like that :-)

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

June 2014

A. Hi Hayleigh

Home brew processes are the way to expensive sleepless nights.

Many published formulations may have worked once in a lab (if that) and few are reliable production processes. In addition, it is next to impossible to get the chemicals in UK.

Ted is right. Go to one of the major suppliers and you can have practically any colour you want with technical advice a phone call away.

If you are not aware of the major supply houses in UK ask the Institute of Materials finishing (IMF). There is a link on this site or go straight to

www.materialsfinishing.org

You may even consider one of their distance learning courses to understand the process.

Geoff Smith

Hampshire, England

June 10, 2014

November 10, 2014

Q. Hi,

I am wanting to Rose Gold Plate sterling silver jewellery.

The rose gold solutions I can find available in the UK at an affordable price point with a long shelf life only plate a gilding layer of up to 0.2 microns. I have an electroplating set up for mini tank beaker plating and brush plating.

I am looking for specifically a Rose Gold colour rather than a Red Gold colour. After exploring the forum and previously speaking to you it seems I have a number of options but I can't decide which would be the best option.

Option 1: Palladium tank plating 1/2 micron diffusion layer tank plating, 2 micron tank plating 24 kt yellow gold, finally 18k Rose Gold gilding layer 0.2 microns --- (I worry how long it will stay Rose Gold for before the yellow gold starts to show through.)

Option 2: Palladium diffusion barrier tank plating, 18k red gold 2 micron brush plated (so can mix less solution so less is wasted as it only lasts 24 hours.) Then 0.2 micron Rose Gold gilding layer. Same problems as above only red may show through.

Option 3: Palladium diffusion barrier, 1 micron gold layer, 1 micron 18k Red gold layer, 0.2 micron Rose Gold gilding layer. Problems may arise as above.

My question is which would be the best option and how long will the Rose Gold gilding layer last? It is for 2 cm pendants, charms for bracelets and earrings (no rings).

I am worried about the gilding layer wearing off unevenly and having part of the necklace red and the other parts rose making it appear blotchy. Is there any way to make this gilding layer thicker? I have an agitator/magnetic mixer with hot plate and wouldn't mind leaving it in for a long while. Or maybe multiple layers of gilding?

Somebody mentioned I could put a lacquer on it, but will this show?

I can get 2 microns with the RED gold solution ... is there any way I can add 2.75% silver solution to the 18k red gold solution? The seller says No, I can only do this with the Nickel solution included ... but I am not allowed to use nickel as it is for jewellery.

Also one of the solutions has 8 grams of gold per litre and once mixed only lasts 24 hrs... I would like to use this for electroplating so need enough liquid to cover the pendant. It seems an awful waste if I only do 1 or 2 pendants then have to discard a whole beaker full of solution after 24 hours ... is there any way I can 'water' it down so there is less grams of gold per liter?

Thanks for your help! This forum has been a lifeline!

Hayleigh Jackson [returning]Jewellery Designer Maker - Maidstone, Kent, United Kingdom

A. Hello Hayleigh,

As far as plating options I would suggest the palladium as a barrier plate with the rose gold being your final finish. I must say that being able to plate 2 microns of gold on costume jewelry is virtually unheard of in the industry. Even in the electronic plating industry a little over 1 micron or less is standard. Costume jewelry is normally plated at 3 - 6 microinches of gold. Anyway, if the rose gold flash plate is successful with the palladium undercoat, you should be fine. People that buy costume jewelry expect the finish to wear over time. Have you thought of using a bigger gold plating tank (1-3 gal), and purchasing a rose gold replenisher? You could add a specified amount of the replenisher to the tank per so many ampere minutes or ampere hours plated. If you don't have an amp hr meter you could just track the amp minutes/hrs the old fashioned way (on paper). Amps x minutes plated, for hours divide total minutes by sixty. The replenisher comes in a liquid with a certain amount of gold and copper to maintain a good balance of your desired alloy (color). Your gold supplier can set you up with such a replenisher with the addition rate per stated amp minutes or hours. Good Luck!

Process Engineer - Phoenix, Arizona USA

November 11, 2014

A. Hi. I would only add to Marks excellent post the following --

While "being able to plate 2 microns of gold on costume jewelry is virtually unheard of", we should note that 'Rolex

[affil link] quality' watches may have 7 microns of gold plating, and top quality pocket watches from a century ago were plated up to 20 microns. It's not that there is extreme technical difficulty with thick gold plating -- it's just that it's not affordable, and that further limits availability.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

November 2014

Looking for rose & gold plating that will survive water or soap

January 13, 2015Q. Hi everyone,

I am about to launch my company in jewels, I make my own designs, and I am actively trying to find somebody who could make them.

For the silver color, problem solved, I will use silver 925 or stainless steel 316L because I think that the ratio price/quality is very good. The quality is good and doesn't fade easily.

My problem is that I would like some of my items/designs (bracelets, necklaces, earrings) to be in rose and gold color and more importantly I want people to be able to wear it everyday (shower, soap, perfume).

I know it exists, and in affordable prices, because there are many stores here in Belgium which sell silver 925 plated with gold or stainless steel plated with gold and give you a guarantee that it doesn't move for 2 years (you can shower with it, go to the beach and everything) and it is very affordable maybe 40 euros for a necklace.

What technique is used? I am trying to find some good prices, I found a wholesaler in China, but the only thing he tells me is that "we always use electroplating and vacuum plating", and

"there is a layer between stainless steel and the gold" but can't tell me what of material is used?.

Could you please help me out? Is electroplating and vacuum plating the same thing? is it PVD ?

When I asked about the thickness in microns of the layer they said "we can't say, it is electroplated". Does that mean it is "flashed" like somebody mentioned in earlier comments, really poor quality?

Some say it means PVD, but I am very confused, if somebody could list the different sort of platings and how long it lasts this would be very helpful.

If somebody knows somebody who makes the designs of others, I could need that as well, because the communication with China is very vague, inefficient, and I don't really know what I would be buying.

In Europe, Italy, would even be better.

I hope some expert will help me out here.

Thank you very much in advance

Aurelie

product designer - belgium

January 2015

A. Hi Aurelie. More than a hundred years ago we knew how to electroplate pocketwatches with gold so they would last a century. You can still buy such plating on ultra-premium watches. This plating was not high technology; it was just very thick so it took many years to wear away. But you want it cheaper -- and that means you don't really want expensive and heavy gold plating like ultra-premium watches -- you want a cheaper finish that will last a passable time, and just looks good.

The way you can do that is some combination of:

a). gold plating thick enough but not that thick, and/or

b). substituting titanium nitride instead of gold as the base layer, and/or

c). adding a clear protective coat as the top layer.

A. High quality costume jewelry is sometimes called "micron plating", meaning the electroplated gold is about 1 micron (40 millionths of an inch) thick. A thicker plating than that, 2-1/2 micron, when done on a sterling silver base is called vermeil.

B. Titanium nitride (TiN) and similar gold-tone materials can be deposited by PVD (physical vapor deposition), a vacuum plating process done in rather expensive machines. The TiN is cheap and it is very hard and long wearing, and looks almost like gold. Sometimes a flash of gold is deposited over it.

C. Clearcoats, ranging from lacquer, to UV-curable (like nail-salon nail polish), to automobile 2-component clearcoats, to high technology clear coats can keep wear from getting to the gold.

If the proposed vendor cannot tell you the thickness of the gold -- in fact, if he cannot give you the complete details of what he is applying -- the chances of it enduring several years of constant exposure is nil. You can get a high quality process, it isn't that hard, but it may not match your price point. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 15, 2015

Q. Hi Ted,

Thank you very much for your concise answer.

So If I get a thickness between 10 and 25 microns it should be good quality if I understood you correctly (since the thickness is important)?

Also, if I understood you correctly, Vacuum plated is not necessarily PVD ? It is Ion plating but that can be done several ways right? Or is vacuum plating PVD?

The offer I have right know is vacuum plated thickness between 10 and 25 microns by paying a little more would that be a good quality?

With that thickness, do they also apply an intermediate layer? would palladium be recommended?

Thank you very much for your answer, really helpful!

Regards,

Aurelie

- Brussels, Belgium

A. Hi again. 1 micron of gold would be quite good quality costume jewelry, 2.5 microns would be outstanding quality. I doubt that you have offers for 10 to 25 microns -- you probably mean microinches. 25 microinches is less than 1 micron (40 microinches), but still probably considered pretty good quality in these days of 6-8 microinches being pretty common :-)

Sorry, I'm not an expert on vacuum plating technologies, so I can't answer detailed questions about them. But PVD stands for physical vapor deposition and, since all such deposition is done in a vacuum to my knowledge, the term probably encompasses all such technologies from the least expensive aluminum vacuum metallizing on shiny mylar balloons through the more exotic technologies on expensive watches. So "vacuum", "ion", and "PVD" are imprecise in terms of what finish is applied and how heavy.

I don't know if they would apply an underlayer of palladium ... I apologize but you can't accept a loose specification from your vendor and then expect a 3rd party to be able to tighten it up. You have to either specify exactly what you want in fine detail and insist upon it ... or you have to get from the vendor the details of exactly what he wants to sell you, and decide whether it's adequate. One thing you might do is have them ship you a few items processed to the spec they propose, and see how they hold up. Me guessing what he wants to do for you from 3rd-hand snippets of conversation isn't going to help much :-)

Buying from China is okay if you are like Apple and big enough to design and oversee production and quality control. Buying from China the way you would like is sometimes cynically called "throwing it over The Wall", which is why the best approach might be to get the samples and hold the vendor to the same quality on your pieces. Best of luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2015

Rose gold plating: relationship between voltage and color

January 26, 2015Q. Good Day,

I am trying to understand the gold and rose gold process relating to plating using current density. I would be extremely grateful if someone could explain this?

Also, why will pink gold plate with with a lower current density?

Both questions are plating to 18K gold with electrolytes.

Does the copper activate first in gold solution?

Many thanks,

Geno

Jewellery - United Kingdom

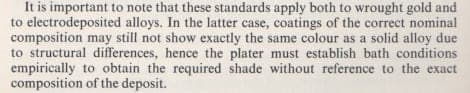

Hi Geno. You probably know more about the subject than I do, but pure 24K gold is always yellow. Any other color is the result of alloying with other metals such as copper. The more gold, the yellower; the more copper, the pinker/redder. According to the previously referenced "Gold Plating Technology", 18K 4N Rose (pink) gold is 750 parts gold to 90 parts silver and 160 parts copper.

The more gold in solution, the yellower and the higher karat the plating will be, but temperature and voltage (current density) also play a role. There are some theoretical tools like the Nernst Equation that may help us estimate how to shift these percentages, and thus the resulting color, by changing the percentages of metals in solution, the temperature, or the voltage ... but alloy plating is complicated theory and we may rely more on empirical knowledge than first principles. Finally, a brief excerpt from the same book:

Luck and Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

January 2015

![]() Thanks Ted.

Thanks Ted.

- United Kingdom

January 27, 2015

June 2, 2016

Q. Hi!

We are a small jewelry producing and marketing company from Estonia. I have read this thread about rose gold plating twice now and done a lot more googling but still have not got straight answers to our questions:

1) Is it possible to achieve 1 micron layer thickness with rose gold plating?

1a) If yes, then how?

1b) If not, then why?

2) Is it the same situation with green gold or is it in some aspects different?

About our situation: we have a vendor for ready gold and rhodium baths from Germany and they say that with their baths it is not possible to achieve more than 0,2 microns (of rose gold) which, as we have found out, wears off in 3 weeks to 6 months max. We are competing on our market with some international jewelry brands who claim they have 2 micron rose gold layers and I know from clients' feedback that their gold plating indeed is very durable, so

3) If achieving rose gold plating of 1-2 microns is not possible, then what would be the best solution for a small workshop to use the other techniques, such as TiN plating, Lacquer, etc., in terms of capital investment?

Thanks a lot in advance!

- Tallinn, Harjumaa, Estonia

Metal Finishing Book - Rose gold plating formula is wrong?

November 23, 2016Q. According to the Metal Finishing Guidebook (2013),

a rose gold plating solution should contain:

6g/L PGC

4g/L KCN

15g/L NaOH

30g/L Soda Ash

I used 0.6g PGC, 0.4g KCN, 1.5g NaOH, 3.0g Soda ash and mixed with 100 ml of distilled water.

I heated the solution and prepared a gold sample to be plated.

The results are not of rose gold color at all. It looked as if there were bits of yellow and a little rose somewhere.

Is this formula wrong?

- Quezon City, NCR, Philippines

Hi John. The formula might be wrong; I see no metal other than gold in the formula, and I was not aware that rose color could be obtained without at least a copper co-deposit -- but I am not a gold plater.

Please introduce yourself and your situation because we don't know if you are an experienced color gold plater wishing to correct this misprint, or a beginner with no gold plating experience ... which could mean a different plating problem rather than a wrong formula being printed in the MFG. Thanks.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

November 2016

Q. I'm in the jewelry and refining business. So yes you do not have to worry about my electroplating knowledge. If you notice on the book itself, the next page after that formula shows the same formula for antique gold finish which is what the product looks like, not rose.

John Cruz- QUEZON CITY

November 23, 2016

November 2016

![]() Hi John, thanks. I wasn't "worried" about your electroplating knowledge, but questions are posed on this site by everyone from 8-year-old children to post-doctural researchers, and it simply helps us all try to answer most appropriately when people introduce themselves.

Hi John, thanks. I wasn't "worried" about your electroplating knowledge, but questions are posed on this site by everyone from 8-year-old children to post-doctural researchers, and it simply helps us all try to answer most appropriately when people introduce themselves.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

|

November 24, 2016 A. The earliest MFG I have is a very beat up copy of the 1968. Its formula for rose flash (or, color) gold is a bit different than in the newer editions but it still contains no copper. Like the newer editions, the formula for red and pink flash golds do contain copper. - Nevada, Missouri, USA A. There is no "Rose Gold" without copper in the formula, a simple "Rose Gold Plating Solution pics" search using your preferred internet browser will show you that all of the formulas look bluish due to the copper ions on the formula. Marvin Sevilla- Managua, Nicaragua November 24, 2016 |

![]() Hi folks. Is it perhaps possible that there is not a universally accepted meaning for "Rose gold"? According to Reid & Goldie there is a standard color "4N" in watchcase plating in Germany, France, and Switzerland which they call Rose (Pink) ... but it has 90 parts silver and 160 parts copper per thousand.

Hi folks. Is it perhaps possible that there is not a universally accepted meaning for "Rose gold"? According to Reid & Goldie there is a standard color "4N" in watchcase plating in Germany, France, and Switzerland which they call Rose (Pink) ... but it has 90 parts silver and 160 parts copper per thousand.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Rose gold plating

Q. can you please tell me the composition of rose gold flash plating of imitation jewellery without the use of gold as the base?

kavita soni- mumbai Maharashtra

April 7, 2017

A. Hello, I tried to reply, rose gold color can be obtained easily if gold mixed copper with composition 1/3 and must fit.

Rizqi andika putraCahaya silver - Kediri indonesia

April 23, 2017

Q. Hello everyone. I'm not a jeweler but an importer & distributor of garment accessories. I was looking for answers as to what might cause a rose gold to tarnish. Currently I sold some sliders and hooks to a garment manufacturer for swimwear. The factory in China says that there are coated for salt test to withstand 12 to 24 hrs. What they do is they plate in rose gold and apply a lacquer. Clients are returning the goods due to tarnishing. The material used for these sliders and buttons are zinc alloy.

Any suggestion or recommendation?

Marina

- Los angeles, California

April 26, 2018

A. Hi Marina. Unfortunately I don't think there is much that can be said except that the plating and lacquer are not adequate. You could have the parts salt spray tested to determine whether or not they actually survive 12 to 24 hours, but whether they do or they don't, they are not surviving your customers' expectations and needs.

The question for someone becomes "who is responsible for insuring that these finishes are adequately designed and implemented?"

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2018

Q. Dear Ted

Thank you for your prompt reply. According to one factory they now tell me they recommend for swimwear to have the 48 to 72 hrs salt test. When pricing we gave the client a choice and submitted samples for approval. Just found out they never did their own testing. They just relied and trusted us. One of the factories agreed to replace the goods but it is too late as the earlier goods are already in the stores.

This client has been ordering for over 1-1/2 years and now the problem is arising. All I can think of is a bad batch, not sure.

For what I learned reading this that rose gold color tarnish especially under high humidity and temperature. This garments are made in Bali, Indonesia.

For sure, I am the one to be blame as I sold this to the client.

Marina

- Los angeles, California

April 26, 2018

Q. Hi Ted. Thank you for your reply. We did put the hardware on salt test for over 38 hrs. And still holding up well. However, the factory in Bali, Indonesia, says that even before leaving the factory they are tarnishing. Do you think it is because of the high humidity and heat in that region? I am trying to find out what other process the garment goes into. Maybe dry clean or something like that that is creating a reaction.

Best regards

Marina

- Los Angeles, California

April 27, 2018

A. Hi Marina. Such problems are unfortunately very complicated :-(

You don't know the actual spec for the rose gold plating (how thick it is, what tests are performed to insure no porosity, what chemical analyses are done to make sure the process is under control). You don't know the specs for the lacquer, and whether it is fully resistant to perchlorethylene or other dry cleaning chemicals, or whether any porosity checks are performed on it. You don't know for sure whether the tarnish is due to corrosion, or not.

While swimwear should presumably be able to resist beach and weather conditions anywhere, you don't know the environmental conditions within the swimwear factory in Bali where the ambient air could possibly be laced with acid vapors (I have no idea what chemical operations, if any, are conducted in that factory (do they only do sewing, or do they also do fabric bleaching and such). Are the sliders and hooks exposed to chlorine bleaching as part of the manufacturing process?

Where are the salt spray tests being done? Here in the USA under your evaluation, or is it just the plating shop in China which is claiming that the parts are surviving 38 hours of salt spray and holding up well?

I think you'll need to get a finishing consultant involved if neither the plating shop nor the Bali factory will accept responsibility for doing something wrong. Presumably you are not specifying the details of the plating process but simply buying sliders and hooks which ought to function as sliders and hooks; however, even there, the plating shop might claim that their sliders were intended for dresses not for the rigors of repeated immersion in salt water which swimwear must endure. I sympathize with this knotty problem but, sorry, I don't have easy answers :-(

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

April 2018

A. Hi Marina

I sympathise with your problem but I would not rush to blame the manufacturer.

A salt spray appears to be an obvious test for swimware fittings. However this will be applied immediately after coating. Fasteners, particularly zips are a very high wear application. I would expect lacquer to have a short service life and the underlying gold will be very thin and therefore porous.

A salt spray after simulated wear would be more appropriate but I fear that the root cause is specifying a cosmetic finish for what would be a challenging industrial application.

Have you considered making the fasteners from a Naval Brass?

It would stand up to salt water much better and have nearly the same colour.

Geoff Smith

Hampshire, England

April 28, 2018

May 11, 2018

Q. Thank you Mr. Mooney and Mr. Smith for your replies. I really don't know the actual Spec. of the rose gold from the factory nor what conditions the contractor in Bali deals with. I will ask the factory and also find out from my client to check on their contractor in Bali.

All I know is that I've been selling for over a year to various clients and only in Bali so far I heard of the problem. My other clients in USA have not had any issue yet. Perhaps the high humidity and heat might be a big influence. I really don't know. Of course, the factory says they have had no problem before and if the client really wants to be safe to choose the rack plating with 48-72 hrs. salt test coating and this definitely will be okay.

When we placed the orders, we specifically mentioned for swimwear and to at least pass the 12-24 hrs salt test.

We did the salt test in the USA. went to the ocean picked up some water and left the metals for a few days in there. As far as I know, the metals were holding up fine.

I never heard of Naval Brass material. So far in this industry the various factories uses alloy zinc for the heavy duty buttons and hardware besides yellow brass.

I am really thankful for your insights and taking the time to help me understand and see what factors might be involved on the tarnishing.

Yours truly,

Marina Sua

- LOS ANGELES, California

Q, A, or Comment on THIS thread -or- Start a NEW Thread