Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Sealing Aluminum to prevent oxidation?

Q. Good afternoon. I did patina on aluminium plates, with oxides and a binder. Then sealed with couple of coats of lacquer. Initially it seemed all good, but after a week started peeling, developing thousands of pits and pushing the sealant away.

Any advice what I can use to stop this please?

- CAPE TOWN, So. Africa

September 25, 2023

Aluminum How-To

"Chromating - Anodizing - Hardcoating"

by Robert Probert

Also available in Spanish

You'll love this book. Finishing.com has sold almost a thousand copies without a single return request :-)

A. Hi Gert.

Aluminum greatly profits from chromate conversion coating, which is a great corrosion preventative for aluminum.

If you don't have industrial connections for chromate conversion coating chemistry, then Alumiprep 33

⇦ this on

eBay or

Amazon [affil links] followed by Alodine 1201

⇦ this on

eBay

or

Amazon [affil links] is available to consumers.

But read the instructions carefully, not only for successful application, but because this involves the notorious hexavalent chromium, and imposes the need for care for yourself and for the environment.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

⇩ Related postings, oldest first ⇩

Q. I am a manufacturer of custom machined aluminum parts, both polished and brushed aluminum, and I would like to know the most economical way to prevent oxidization and keep a long lasting finish on the product. All of the parts that I make are for automotive detail/finishing for either engine compartments or interior such as radio trim pieces, speaker grilles, sill plates, radiator covers, etc.

Kyle Williams- Omaha, Nebraska, United States

2003

A. Hello, Kyle. The two common alternative approaches would be anodizing or clear coating (which in turn can be one part or two-part, applied by spray or brush, or a powder coating). They are all rather different, and it may depend a bit on the look you want as well.

Multiple approaches exist because there is no one best approach for all conditions. It may be that anodizing is appropriate for some of the parts and different types of clear coating for the others ... but since you asked for "most economical", a one-part spray-on or brush-on clearcoat will surely win by that measure.

Good luck

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. I've been using a spray clear coating on architectural aluminum for 2 decades with wonderful results.

Bruce Smith

metal refinisher - Hayward, Wisconsin, United States

Q. Please tell me more about chemical that can be used for sealing of aluminum material.

Thanks.

- Ho Chi Minh City, Vietnam

2006

Q. How can I find the spray on sealer for Aluminum?

Thanks Rob

- Embudo, New Mexico, USA

May 30, 2008

A. Hello, Nguyen, Hello, Robert.

One-part clear coats for aluminum are available from many sources including Everbrite [a finishing.com supporting advertiser]. Two-part clear coats are available as "automotive clear coat"; these cure by chemical reaction (like epoxy) rather than by drying, so they typically use professional spray equipment, but they can apparently be done with specialized aerosol cans which spray both components at once, although I can't comment on how well this product works or doesn't.

Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

May 2008

Q. What clear topcoat (brand) is best to protect brushed aluminum? I have used Rolite Premium polish and sealant that wipes on and off with some success, but I want to retain that bare, metallic look so am looking for the optimum sealant/protection.

Tom PopeFinisher - Clearwater, Florida, USA

November 17, 2010

A. Hi, Tom. You wouldn't believe the number of postings we've received where the URL proved that a "satisfied customer" was actually a hawker from the supplier he was recommending :-(

Sorry, but we only talk technical issues here, like technologies and types of clearcoats, not specific brands (huh? why?) :-)

But Everbrite [a finishing.com supporting advertiser] is certainly a reputable brand.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. What can I use for sealing edges of anodized aluminum weldment? I'm trying to seal the unwelded portion. Corrosion is starting to leach out. Clear or dark gray caulking sealant?

Armando amoranto- Seattle, Washington usa

January 18, 2012

A. Hi, Armando. The best surface protection would probably be chromate conversion coating followed by a 2-component or powder coated clearcoat on any surface that isn't anodized.

But when you mention caulk, it sounds like you are talking about a capillary crevice, such as between two sheets in a stack. Sealing in the remnants of acid doesn't sound promising to me, but better rinsing during the anodizing process (hot & cold, and including a dilute nitric acid or sodium bicarbonate dip) usually helps. Alternately, sealing the parts with an anaerobic adhesive before anodizing may work too. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. What would you recommend for cast/extruded aluminum materials, to protect the powder coating from oxidation or fading?

Paulena Jaks- Toronto, Ontario, Canada

May 19, 2016

A. Hi Paulena. Are you saying a clear coat is fading, or are you moving the discussion from clear coats to colored powder coating? In any case the substrates must be properly pretreated before powder coating, which probably means a chromate process or tri-chrome process (please see MIL-DTL-5541 [⇦ this spec on DLA] for this). Then a polyester powder coating rated for UV resistance -- this is crucial.

(what a difference UV inhibition makes)

If you can offer details of your situation, you can probably get specifically targeted advice rather than just truisms :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Just saying thanks for the info. It really helped.

Just saying thanks for the info. It really helped.

- Mechanicsville Virginia USA

June 5, 2016

Q. Hi. Just read your responses to the clear coating of aluminum.

I am working on restoring lawn chairs which have tubular aluminum legs and arms. Some I am replacing while others will be re-used. Some of those have marks, grime, pits and stains. I have burnished with 000

⇦ this on

eBay

or

Amazon [affil links]

. Is there any recommendations for a layperson? I was wondering if a 'dry lube' could work but would prefer a clear coat?

Your thoughts?

Mike

- Cleveland Hts, Ohio

July 6, 2016

Q. Please advise if there is a product to seal painted aluminum soffit to slow or stop the growth of mildew. I really don't understand what is happening, on the front of my garage, one side of the soffit is clear of mildew but at the seam it starts to mildew and follows that piece the rest of the way across. there are other places that do the same thing. Looking for a solution and thank you for any light you can shed on the subject.

dee moore- savannah, Georgia USA

August 11, 2016

A. Dee,

Your paint supplier can sell you specialty primers and paints designed for this particular problem. A couple of ideas: Check gutters and moisture sources to be sure excessive moisture is not affecting the problem areas. Frequent power washing and scrubbing may be needed. Mildew hates hot dry sunlight so maybe it's time to trim some tree limbs.

Blake Kneedler

Feather Hollow Eng. - Stockton, California

February 5, 2017

Q. Hi,

I recently polished the wheels and front forks, etc., on my 1998 Honda F6 motorcycle and wanted to protect the shine and more so to stop oxidation. The original aluminum was protected by a clear coat which the manufacturer applied. Can I apply a one or two part clear onto the parts? Will it adhere. I have spray equipment.

- Galway, Ireland

December 20, 2016

Repairing oxidation (and protecting) aluminum garden stools

Q. Hi,

I recently purchased these aluminum garden stools for outdoors .

after a few days in the rain, they oxidized and have spots all over them! :(

I didn't exactly think that one through, as there has been a lot of rain in my area recently.

I purchased Star brite Aluminum Cleaner, which I noticed has sulfuric acid in it.

My questions...

- will Star brite (I hope) repair the oxidation?

- after removing the damage from oxidation, I'd like to protect it from further incidents.

I'm planning to use Rust Oleum 280702 American Accents Ultra Cover 2X Spray Paint, Gloss Clear by Rust-Oleum to seal it. Will this work well to protect it during rain, and from oxidizing?

Should I polish it before I seal it, say with Mothers Mag & Aluminum Polish?

⇦ this on

eBay or

Amazon [affil links]

Thank you for your help! :-D

Laura

- Huntington Beach, California

February 27, 2017

Q. I work for a group that travels with horses. Several stalls are partially aluminum and wham the horses run on them (scratching themselves) they tend to get aluminum dust stains. This is lousy before a show on white horses.

What would be a suggestion to safely seal the stalls?

Safe for the animals in case they lick it.

Thank you so much.

Odysseo - Portland, Oregon USA

July 29, 2017

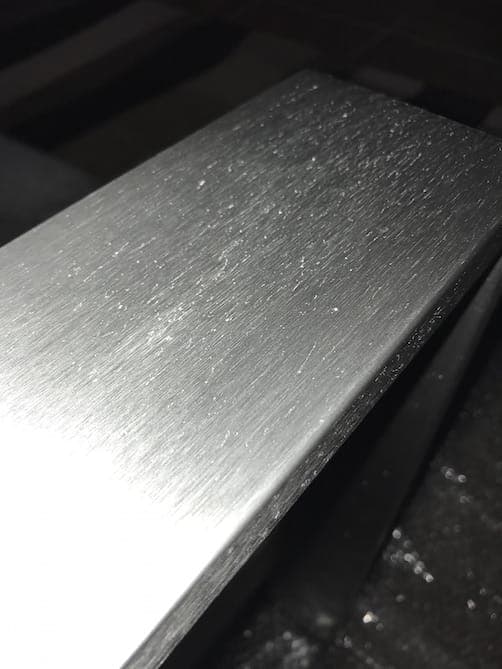

Clearcoat for deeply brushed aluminum

Q. I am trying to put a protective sealant on some aluminum patio furniture. It is a brushed aluminum, but with a very deep grain. I bought Everbrite ProtectaClear for the application. This is actually the third time I've used their products. I have always had good success with them. But this time when it dried there is a definite roughness which, even with light strokes, causes it to flake off. Previous applications were on smooth metals without a grain.

I followed the directions, cleaning off the new metal with denatured alcohol and then applied two coats with over a 1 hour drying time in between.

I believe the grain of the brushed aluminum is so deep that as it dries between the peaks and valleys it is causing this easily flaking result.

I am going to remove it with Xylene

⇦ this on

eBay

or

Amazon [affil links] as per their website's recommendations. Will do a test spot to make sure it doesn't discolor the aluminum.

Any recommendations on either how to improve this application or do I need a thicker type of coating? One that would level out over the grain. Like a shellac for metal, if that exists. Would a spray on clear coating do better?

Any help would be appreciated.

- Staten Island, New York, USA

May 1, 2018

Q. I am building a hotrod, I'm doing fine with brushing and polishing all the aluminum parts. Now I need a clear finish that will withstand some heat. Any ideas?

Ron CorriganRetired - Holden, Missouri, USA

May 11, 2018

Q. I bought a highly polished aluminum propeller blade that I would like to install outside as a garden sculpture. What product will protect this from weatherization? A company recommended Protectaclear - would this work, and if so, can it be applied directly to the object without any advance surface preparation?

Anne McLane- Rochester New York USA

July 12, 2018

A. Hi Anne. We don't post recommendations of one proprietary product over another (why?)

But, yes, Protectaclear from Everbrite [a finishing.com supporting advertiser] is a reputable product for the purpose. It would be unusual if your item were completely free of dirt and fingerprints; it probably should be lightly scrubbed with dish detergent before coating. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi everyone!

I make a polespear for lionfish out of type 6061 1/2" aluminum tubing and need to find a decent clearcoat for these shafts after bright polishing. Suggestions?

Keep in mind they are exposed to a lot of salt water and sunshine!

I'd love to hear any suggestions!

W

- Sidney BC Canada

April 7, 2019

A. Aluminum should not be in autoclave tanks, automobile bumpers, or anywhere near salt water -- use stainless steel tubing.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

Q. Sir.

With all due respect there are dozens of aluminium boat manufacturers in the Pacific northwest these days! I am using the same grade metal in my product. Surely someone has a more positive response to my question! Thanks though ...

W

- Sidney BC Canada

A. Hi Walt.

If you go with aluminum, the best approach would be full proper pretreatment including alkaline cleaning, etch, de-smut, and MIL-DTL-5541

[⇦ this spec on DLA] chromate conversion coating followed by 2-part epoxy coating or other coating which relies on 'curing' rather than 'drying' (UV cured, powder coating, etc.)

Full mirror appearance may not be compatible with sufficient corrosion resistance, but you could try a single-component clearcoat like Protectaclear from Everbrite [a finishing.com supporting advertiser] or a 2-part automotive clearcoat, with or without the chromate, and see if you are satisfied with either.

Readers are encouraged to suggest types & technologies of clearcoats or other corrosion resisting treatments, but there are dozens if not hundreds of individual brands and we can't post testimonials to specific brands or suppliers (why?).

Economics, weight, appearance and other factors may well demand that your product be made of aluminum! Still, Robert Probert is one of the world's best known experts on aluminum finishing. Finishing.com alone has sold over 850 copies of his wonderful "Aluminum How-To -- the Chromating, Anodizing, Hardcoating Handbook" without ever even a single return request -- so other readers considering tubular products for salt water use may well find his response quite valuable even though it's not a positive one for you :-)

Regards, and Good Luck!

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

You are right about economics and weight in regards to the polespears we're making. They are lightweight and fast which is what our customers appreciate.

And yes a single component clearcoat suits us better for economic and time constraint/production reasons. We currently use a product called shark_hyde that does the job but I wonder if there is a better one to try?

I will look into Everbrite as you suggested. That is all very helpful information!

Thank you gentlemen!

W

- Sidney BC Canada

A. You're welcome, Walt, and best of luck! I linked above to the list of reasons (why) we can't compare brands & proprietary products in this forum, but just consider ...

... if I said our supporting advertiser's product was better than the brand you named would you & readers believe me or would you say we're just speaking out of vested interest?

... yet if I said their product wasn't as good, how could we ever have advertisers to make the site possible :-)

Sorry, but there's simply no solution to that problem except "no brand comparisons" :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

adv.

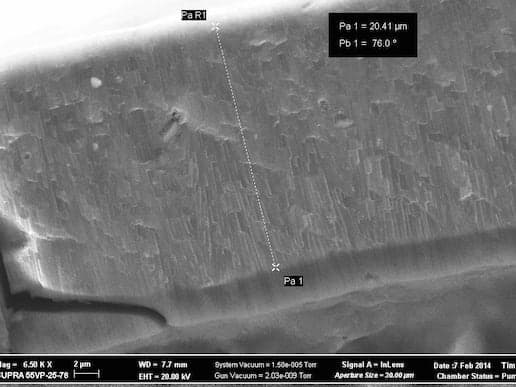

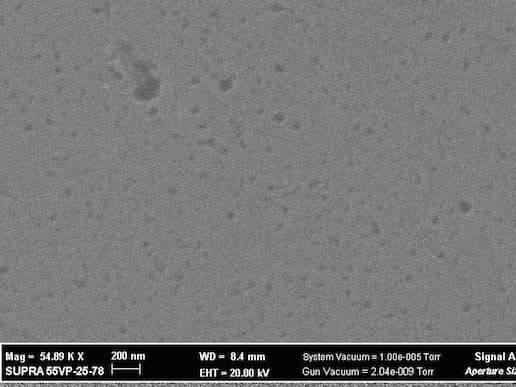

It is possible to anodize aluminum to what looks like ceramic or glass, super strong and corrosion resistant layer. It will definitely stand salt water conditions. Depending on aluminum alloy composition, the color can be glass-white, blue or greenish. The average thickness is 30-50 microns. See images attached.

(thickness of ceramic anodizing)

(pores)

Contact me for samples testing.

Anna Berkovich

Russamer Lab

Pittsburgh, Pennsylvania

![]() Thank you Anna!

Thank you Anna!

That is definitely something we'll consider down the road.

I appreciate the advice!

Walt

- Sidney BC Canada

Q. I have a cast aluminum fountain which all the paint has flaked off due to corrosion underneath. How would I refinish this so the corrosion does not occur again?

Georgia Arriola- Tamuning Guam

June 19, 2019

A. Hi Georgia. You should sand it as smooth as practical to reduce the number and depth of pits. Then, if you are an industrially qualified applicator, you should do cleaning and chromating (Alodine). If not, you can apply rust-inhibitor -- this is designed for steel, not aluminum, but it will at least etch the aluminum. Then you can apply a primer made for aluminum, and then top coats of whatever color and gloss you prefer. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello everyone; I am a retired electrician who now shows and drag races a 1970 Olds 442.I recently put new aluminum heads on the engine and coated them with Sharkhide ⇦ this on eBay or Amazon [affil links] to keep them looking good.That unfortunately did not do the trick because of the fuel and oil that gets on them. Now I am looking for another way to keep the aluminum looking fresh, that won't yellow? I cleaned them with lacquer thinner ⇦ this on eBay or Amazon [affil links] Warning! flammable! and a brush but I could use something else because the engine is out of the car and partially disassembled right now. Soap and water would not be out of the question. Any suggestions or help will be greatly appreciated!

Charles McCann- Davison, Michigan

October 11, 2020

A. Hi Charles. We don't comment on brands or sources here, but as for types it would seem that a two-part automotive clearcoat would be more robust than a single-part one; and fuel & oil don't seem to be a major issue for automotive clearcoats.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello...

I fabricate complex frames for towing very sensitive magnetic sensors through the sea. I predominantly use aluminium as it's broadly non-magnetic. The frames that I build have to be very precisely aligned prior to being welded into place. Prior to jigging these parts up I need to clean the aluminium of unwanted anodizing and Aluminium scale (corrosion surface)

It sometimes takes weeks between jigging up these parts and having them welded.

Can anyone advise me of a simple way to seal the aluminium after cleaning the parts and prior to jigging the parts up and having them welded.

I cannot leave it to the welding company to jig the parts up as a fraction of a degree of error makes my frame hydrodynamically unstable.

- Leighton Buzzard, UK

April 27, 2021

Using trivalent chromate should solve the problem and give you enough protection before your processing. I know of 3 -4 companies who make one.

adv.

If you send me an email I will send over that info.

Drew Nosti, CEF

Anodize USA

Ladson, South Carolina

Q. Hello experts,

I am in a rather unique position compared to your normal inquiries, but my google skills are failing me and this seems like a good place to ask. I play in a game that requires armor (think renaissance faire). I have aluminium chainmail, and while it's light and looks great, it leaves black or silver residue on everything. Just putting it on leaves black marks on my hands, the clothing underneath is black or silvery by weekend's end and I worry about sitting on other people's camp chairs.

I believe it is oxidation due to sweat, but no-one in my group knows how to stop it. Wax? Sealing spray? The fact that it's round rings makes me wonder about coverage. Thanks for any help you can provide.

Aaron DingmanHobbyist - Ottawa, Ontario

July 18, 2023

A. Hi Aaron. That black dust is the nature of natural aluminum surfaces. Yes, it's oxidization that rubs off.

One answer is to have the aluminum anodized, but that is probably prohibitively expensive and might be impractical.

The best you'll be able to do yourself is probably a 'clear coat', of which there are lots of different types from many different suppliers. The problem with wax is that, while it probably will help somewhat, it doesn't last very long and it's not possible to get good adhesion of a clear coat (or any paint) onto wax, so you'd have to get rid of all traces before you could successfully clearcoat it.

A two-component automotive clearcoat is the most durable type of clearcoat if you have a friend or local shop who can do it for you affordably.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I was wondering if an anti-rust spray or something like a wheel coating would do it, as presumably anti-rust or rust-check style sprays act by preventing oxidization and therefore might prevent oxidization in aluminum or are the processes too different for that? And are automotive wheel coatings intended to prevent corrosion or some other effect? I'm having a hard time finding whether they would help or not. Sorry to double dip on my question, I'm just hoping to find something I can do myself that doesn't require a paintshop or garage.

Aaron Dingman [returning]- Ottawa, Ontario

July 19, 2023

A. Hi again.

Rust preventatives will probably rub off worse than the aluminum.

I'm not quite sure what you have in mind with "wheel coatings", but presumably clear coats of some sort. You can apply clear coats yourself. Single component stuff like Protectaclear from Everbrite [a finishing.com supporting advertiser] are easiest; 2-component types will last longer but require mixing in a "hardener" (they don't 'dry', they chemically 'cure'). So although spraying is easiest for the 2-component stuff, you can brush it on if you want -- but your mixing cups and brushes will have to be thrown away because they'll harden.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

----

Ed. note: For additional situations, options, and opinions please see:

• Thread 23481, "Polished Aluminum Clearcoat Secret"

Q, A, or Comment on THIS thread -or- Start a NEW Thread