Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Ammonium Bifluoride

Q. What is ammonia ⇦ this on eBay or Amazon [affil links] bifluoride? What is its context in cleaning steel-substrate?

Jack Lim- Penang, Malaysia

2001

A. Ammonium bifluoride is a white crystal salt that when put in water forms HF. It is used to brighten aluminum and other metals. This chemical does an excellent job in brightening.

NL [last name deleted for privacy by Editor]- Atlanta, Georgia

A. Hi Jack. Fluoride ions are the only thing that I am aware of that can dissolve silicon. Stainless steel castings, aluminum alloys, and some other metals may contain silicon which often must be dissolved or removed from the surface as part of the finishing process. For example, you can't anodize aluminum if it has excess silicon at the surface. But, as far as I can think of, it wouldn't be used in cleaning steel.

If properly managed, ammonium bifluoride can be somewhat less biohazardous than hydrofluoric acid (see thread 94/62, "Hydrofluoric acid vs. ammonium bifluoride").

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Can we use Ammonium bifluoride for crystal shining process? We use HF currently.

Asim Emirab-ka - Turkey

2006

Hi Asim. This site focuses on metal finishing, and I don't know a lot about glass or crystal finishing . . . but hopefully a reader who can help you will wander onto this page.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have a concern. We are currently using Patclin 975 (ed. note: now Accu-Labs, Inc. [a finishing.com supporting advertiser]) to brighten the aluminum in our plating line. I have to switch it to Ammonium bifluoride, but I am not sure the make up. Should we add Nitric acid or make it up with just water. I have a 6.2 gallon tank, so I don't know the appropriate amount of Ammonium bifluoride needed to makeup the solution. Any Ideas? Ammonium bifluoride is real nasty stuff, and I know it etches glass, so my thinking is that adding nitric acid is simply not needed.

Tim Shea- South Deerfield, Massachusetts

2001

A. Please don't mix proprietaries like Patclin with non-proprietaries like nitric acid or ammonium bifluoride. Either take Patclin's advice, or switch to one of their competitors and take their advise, or start from raw chemistry. There is danger in adding things like ammonium bifluoride or nitric acid to a proprietary, because you don't know what's in the proprietary!

Nitric acid is one of the few oxidizing acids and its oxidation power is required for some applications. For example, copper does not dissolve in simple acids, but excesses of it must be removed from the surface of copper-bearing aluminum alloys before they can be anodized.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. I'm not familiar with the Patclin product, but we've used scratch-built etchants here for years, including those with ammonium bifluoride.

We use nitric acid solutions ranging around 50% with anywhere from 1% to 10% ammonium bifluoride as a de-oxidizer/etchant. I would not use it as a brightener, it leaves more of a matte finish, but that resultant finish is dependent upon the aluminum alloy.

If you're looking for a bright dip, there are far better and safer solutions than bifluorides.

Bob Denneyavionics Tampa, Florida

RFQ: Dear Sir ,

Please advise if you can provide us with ammonium bifluoride that we are seeking to import 2 FCL ,please quote us your best quotation , CIF Alexandria Port , Egypt.

Regards,

Ahmed SadekIMPORT EXPORT - Cairo, Egypt

2005

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Q. I am looking for a pickle bath make up to strip some cast parts. I heard of a nitric ammonium bifluoride solution. What ratios? Are there other more suitable baths?

C Culp- Tualatin, Oregon, USA

2000

A. The usual solutions for the removal of scale and rust from iron and steel products are hydrochloric or sulfuric acids. These are used in concentration ranges from a few ounces per gallon to very concentrated, depending on the type of work being processed. Cold rolled can be processed in weak hydrochloric acid, whereas heavily scaled construction plate is best pickled in sulfuric. Also the use of an inhibitor are common and are optionally used to prevent over-etching and to avoid pitting.

Best regards,

Rob Wells- Pickering, Ontario

2000

A. Hello, C. We are probably misunderstanding you. What material are the castings made of (aluminum, stainless steel, bronze, cast iron)? And what coating do you want to strip off of them (paint, powder coating, a metal plating of some sort)?

We don't know what coating you are trying to remove, nor what substrate you are trying to not harm, so the general implication of Rob's reply would be that you don't use ammonium bifluoride except when it is required (because it is a severe biohazard). Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

March 1, 2013

Q. We are presently making up a nitric acid/ammonium bifluoride

etch solution for aluminium. We are decorative anodising Jig Plate but are having problems with the finish, white spotting and stains. We believe as Ted has stated to have silicon in the aluminium.

The nitric acid in the solution is 50%. What addition of ammonium bifluoride should we add to the bath.

- Northern Ireland

July 17, 2015

|

|

A. One pound per gallon.  Robert H Probert Robert H Probert Technical Services Garner, North Carolina  July 17, 2015 July 21, 2015 Good day Nigel. Lab Tech. - Whitby, On., Canada. |

Q. Robert / Eric.

Thanks for your feedback on this. Our tank size is 400 litres. We have already added 25 Kg which equates to approximately 9 ounces per gallon. This seems to work well but if need be can move towards the 16 ounces. Our immersion time is 25 seconds.

Just a note. We are going into the nitric/ammonium post anodise for 25 seconds. We are aware that the anodic coating may strip so we are being very cautious. We did trials pre and post anodise, and post anodise is giving us a better finish. No white spotting or stains after dying and seal.

Regards

Nigel.

- Northern Ireland

July 23, 2015

A. Hi Nigel,

Interesting that you can apply nitric/ammonia bifluoride etch post anodize before seal. At 25 sec dip time, understandable it may remove some of the anodize coating but, as a point of interest, does it make the anodize whiter in appearance ? Thanks.

cheah

- Penang Malaysia

July 23, 2015

info Hi SK,

We actually dye the parts red. The nitric / ammonium dip pre dye and seal brightens the anodising leaving the finish with a real sheen.

Regards

Nigel.

- Northern Ireland

July 27, 2015

Q. We are working on ammonium bi-fluoride market. I don't know much about the chemical but that it is used as finishing products and sometimes in cleaning process ... I just want to know how much of this chemical holds as the percentage of specialty chemicals (E.g., 10% of all specialty chemicals sales approximately).

Aakansha TyagiStraits Business Group - Pune, Maharashtra, India

March 6, 2018

March 2018

Hi Aakansha. Yes, it is used in finishing products, certain cleaning products, glass etching products, etc. Apparently, somewhere around a million pounds is produced annually.

I think you would have to be very clear on exactly what "specialty chemicals" means to you before anyone could try to answer that question because per Wikipedia and other sources, ammonium bi-fluoride sounds more to me like a commodity chemical or pseudo-commodity chemical than qualifying as a "specialty chemical" (although I don't know of a list of one vs. the other).

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi Mr.Ted Mooney,

So you mean to say about a million pounds of this inorganic chemical is being produced annually round the globe?

Actually as I need to find the market for the chemical and I am not sure about it, so I was considering it under specialty chemicals.

Also the chemical does not have any analytical use such as in research and other fields?

Also as being a toxic substance, is it preferable? And after China which is the largest producer of the chemical?

- Pune, Maharashtra, India

March 8, 2018

March 2018

A. Hi Aakansha. When questions are posted I try to spend a few minutes of googling so I can learn from them, and as a courtesy to posters to not leave there questions unaddressed ... but I'm a plating equipment engineer not a chemical market researcher. I quickly found a reference which said a half million pounds was manufactured some years ago with projections of about a million by now; don't rely on my second-hand numbers though, find the sources of the data yourself.

Ammonium bifluoride is sold in reagent grade; I'm not sure about analytical grade or possible analytical uses.

Sorry, I don't understand what you mean by "being a toxic substance, is it preferable?". Certainly if a less toxic but affordable alternative is available for some particular purpose, that alternative would be used. In some ways it's less dangerous than hydrofluoric acid and is used as an alternative to HF in some applications. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Hi Aakansha, Ted,

Ammonium bifluoride is sold in analytical grade for some uses, we use it to remove iron in chromate analysis (you make an error in excess by oxidizing iron if you don't add it).

As Ted said, it is widely used as an alternative to hydrofluoric acid, and I don't know whether there is or not some safer alternative.

I think that if you are working manufacturing this product, the best you can do to know better the market is going to your actual clients and see for yourself what do they make with your product.

Best of luck!

TEL - N FERRARIS - Cañuelas, Buenos Aires, Argentina

March 9, 2018

Q. Hi,

I did a goggle search and found your website. It's very interesting and so helpful.

Can you please let me know if the Ammonium bi-chloride ^bifluoride is good to remove aluminum silicates? It appeared as a white residues on my aluminum parts.

How much ABF should be used and how long to dip it? Or, do you have any suggestion for other chemicals?

Thank you.

- Houston, Texas USA

September 26, 2018

September 2018

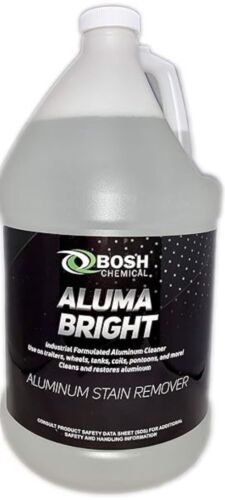

A. Hi M. Commercial cleaners available to consumers are dangerous and contain 2-5% ABF. But whether that is the right strength for your application and how long you would need to dip those parts with unknown amounts of silica stain is hard to say ... but in order of magnitude probably several seconds to a minute or so; certainly not hours.

Chloride and fluoride are very different things and you need to be very careful of typos that could mislead you or others. You didn't introduce yourself and your situation, so we're not confident that you can safely use such fluorides (for example, is this an industrial application in a plant which has a safety program including haz-mat training? do you have calcium gluconate gel ⇦ this on eBay or Amazon [affil links] on hand?). People are reluctant to suggest using fluorides unless you're quite sure what your white residues are. Where did they come from, what's the process? Would avoiding them through the use of DI water be more practical?

Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi Ted,

We are working in an industrial plant that participates in a Safety program. Our workers in the plant miscalculated and over-used a heavy-duty cleaner, so the aluminum parts got white residues after the cleaning process. I sent the sample to a lab and it was identified as aluminum silicates.

I goggled and found your group discussed about the HF and ABF. (Sorry, my question is for ABF, Ammonium bi-fluoride, not chloride. It's a typo). Very interesting and very helpful.

In 2001 you posted "fluoride ions are the only thing that I am aware of that can dissolve silicon". I heard about the HF, but would like to use the AMF because it's less hazardous than HF (according to the discussions in your group). Would you please give me some advice about the ABF? I just need to use it to remove the Al silicates from our 10 pieces of cast aluminum parts. Should I need a corrosion protection after the cleaning with ABF?

Thank you for your help.

- Houston, Texas

September 28, 2018

A. Hi again. Several seconds to a minute of so in 5% ABF is the best guess I can make from this distance. No guarantees that this will fix your problem though, because over-etched aluminum may have other alloying ingredients left on its surface besides silicon. It's hard to say what corrosion protection you need, but aluminum is frequently chromate conversion coated. You might consider sending the parts to an aluminum processing shop who can etch, desmut, and conversion coat them for you. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

September 2018

Q. Hi.

I am a chemical dealer suppling HF to aluminium utensil factories; they use diluted HF acid (20% to 30%) for dipping aluminum. I want to know how much % age ABF should be mixed in HF acid for better shining of aluminium.

And please also let me know if ABF be used for shining S.S.?

- Chandigarh India

October 19, 2018

----

Closely Related Threads:

Letter 9462, "Hydrofluoric acid vs. ammonium bifluoride -- are they interchangeable? Is one safer?"

Letter 34536, "How to Do Ammonium Bifluoride Analysis"

Q, A, or Comment on THIS thread -or- Start a NEW Thread