Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

How to Metallize and Electroplate Resin

Q. Hi, I recently purchased a small brush plating kit to use in spare time to gold and silver plate my small resin model figurines, but am having an issue ... different sites tell me different things, some say I cannot perform this with just a brush kit, that the items need to be dipped ... others have said its too hard and then just ignored me, I really need the help and will just try experimenting if nobody can guide me.

Firstly I understand I would need a metal paint or spray but which do you feel would be best to use?

Then I am aware of the copper plating before nickel and gold or silver but the processes and voltages used are a slight confusion.

I have only used the brush kit twice to gold plate some small pieces of medical grade stainless steel for a friend, I feel I have maybe taken on something too hard to achieve with the tools I have, but if it is possible to help me gold plate over resin with just my brush kit then please let me know as I'm starting to get a little agitated by the lack of industry help!

Thank you Aaron

- Kidbrooke London England

October 24, 2019

A. Hi Aaron. I think the thing is that you should try to enjoy playing around with your hobby, and see what you can learn a small step at a time, as opposed to trying to read just enough to make a leap to much greater levels of difficulty. There is so much to electroplating that many of us have worked in the industry for 50 years and only know a small piece of it.

The more money you spend -- example, silver-based metallizing solutions specifically designed for subsequent electroplating rather than metallic copper paints -- the better the likelihood of success; and copper plating before nickel plating before gold plating will surely be "better" than gold plating directly on copper paint. But I think it is unlikely that anyone will be able to answer the question "Can Aaron brush plate his resin figurines to his satisfaction and how should he do it?". Best of luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

October 2019

⇩ Related postings, oldest first ⇩

Q. The primary object of my Company is the production of silver and gold plated flatware, holloware and giftware. We are accustomed therefore to plating nickel silver, stainless steel copper and zinc.

We have been approached by an African artist who is producing the most wonderful ethnic carvings out of wax. He would like us to reproduce these from resin and thereafter electroplate them with gold or silver.

We want to find out the best method for metallizing and plating resin.

We look forward to a response.

Best regards

housewares - Zaire

1996

A. I am buying both spray-application silver and silver paint that we use to silver coat wax mandrels. We then copper electroform the final product and evacuate the wax. I think the material we use would probably work great to get a conductive surface on resin.

Bill Vins

microwave & cable assemblies - Mesa (what a place-a), Arizona

A. Robert, You went from plating wax to resin. Which is it? Both are done by us but we plate polyester resin which is cast in rubber molds. We use different methods for different items. Being in the jewelry industry we get an assortment of items.

You have to etch the resin which is tough for polyester, once that is done you sensitize with tin or palladium and then metallize with silver nitrate either in an oblique barrel or with a spray gun.

As for wax, the only thing that works is silver paint. Wax exudes too much oil for our other methods to work.

Are you putting gold or silver directly on the piece or copper? What are your specs?

Good luck

- Rhode Island

![]() Dear David, your responses to letters at finishing.com show that you have a very generous nature. Thanks, I think this last letter is a great one and will certainly help our readers.

Dear David, your responses to letters at finishing.com show that you have a very generous nature. Thanks, I think this last letter is a great one and will certainly help our readers.

Best Regards,

Tom Pullizzi

Falls Township, Pennsylvania

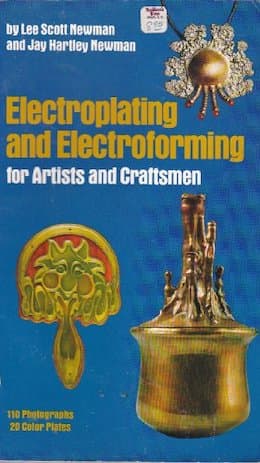

by Jay H. Newman

on AbeBooks

or eBay or

Amazon

(affil links)

Q. I am interested in plating metal and non-metal surfaces in gold, silver, bronze, copper, chrome etc.as a hobby. I want to plate jewelry, bathroom fittings, etc.

I am a pathology chemist and therefore have some chemistry training.I also have some electronics knowledge.

Are there any books or magazines that can show me how to set up do-it-yourself systems and how to make my own solutions, power supplies.

Brush plating seems interesting and flexible. Also, are there electroplating systems that don't use metal cyanides?

I would appreciate some guidance.

JM

Coogee NSW - Australia

1998

A. Please see our FAQ's on this subject, and other hobbyist letters through the years, and for the latest effort in home plating, see me at work on my latest formula for zinc plating at letter 1222. There will be a rash of silvery pennies on the East Coast shortly.

It is very difficult to make plating solutions without the use of toxic chemicals, especially if you are fussy about what kind of metal you want to plate. Jewelry might be worthwhile, but only the custom, artsy stuff, plumbing is definitely out. I don't have the formula, but some of the titanium pieces with the rainbow colors (anodizing?) are really beautiful, and sell in the high class resort shops. I won't look back now to find it, but artists have listed some reference to finishing for artwork on these letters, I think. Artists are not going to share all of their trade secrets for obvious reasons.

Tom Pullizzi

Falls Township, Pennsylvania

1998

A. Hi, James. Follow this link to the list of books you were requesting. The single best one might be the

Metal Finishing Guidebook because it covers a lot, and ought to be reasonably inexpensive since thousands of copies are printed every year and you don't need the latest edition. Follow this link to the list of specialty journals about plating that you are seeking.

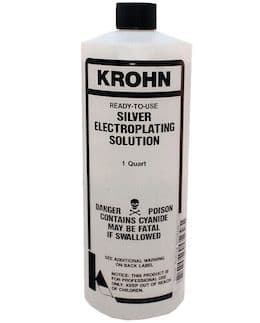

Regarding chrome plating we have an online article "Introduction to Chrome Plating". Bronze plating and real silver plating will require cyanide-based electroplating solutions, but you can deposit a very thin layer of silver from less toxic stuff: See our "Silver Plating at Home" FAQ.

It is not easy to make certain plating solutions because they require proprietary addition agents which, even if you could discover them, require synthesis rather than simple mixing to create.

After taking a walk through the materials we have identified for you, please feel free to come back with followup questions. Good luck!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

1998

Q. Please help me with a plethora of questions:

I've been told that brighteners are reducing compounds that assist in even metal plating.

I believe that they are organic compounds is this correct?

Are they mixtures?

Are they listed in the public domain or are they usually kept as trade secrets?

If in the public domain can you give me examples?

Are there universal brighteners that work for all metals or are they usually specific for a plating formula?

Also, some companies sell manuals, power supplies and kits for hobby plating (some claim that cyanides are not used in their formulas). Is there anywhere I can read an independent review of the quality of plating.

Is brush plating as easy and convenient as the companies promoting it make out? It seems to me to be a good way of gold plating bathroom taps etc in situ.

- Australia

A. I don't believe that "reducing agents" is a useful way to describe them. Lowenheim's

"Electroplating"

⇦[this on

eBay ,

Amazon,

AbeBooks affil links]

(McGraw Hill) states that "most effective additives increase the activation overpotential at the cathode, but there are exceptions". See our Library for a list of

"must have" books.

Some are organic.

Some are mixes.

Most good ones are trade secrets or patented.

Cane sugar in my zinc plating bath with almost zero throwing power. You almost need a conforming anode to plate the little spot under Abraham Lincoln's nose on a US penny. (See?), the good ones are secret.

Specific.

If you find a review, let us know where! When it comes to buying the right equipment, no matter what you read, you will have to leap in somewhere and start doing. I wouldn't spend too much money until you have tried plating using a 1.5 volt battery and some beakers [beakers on

eBay

or

Amazon [affil links] full of chemicals. You will find that you can't do much unless you buy proprietary additives, and you will have trouble buying in small quantities. I doubt that you can get a lot of plating done unless you devote a small business to it, essentially opening a small shop so that you can have the right safety and production equipment, and have a place where it is legal to ship the hazardous chemicals needed.

Everything is easy when you know how, and have the right equipment. You can plate taps in situ. By any chance, did you look over our directory for suppliers of brush plating equipment and supplies?

Tom Pullizzi

Falls Township, Pennsylvania

Q. My partner and I are in the process of setting up a 'cottage'-level (no employees, really intended to simply supplement retirement income) jewelry-making business. In the course of enquiries now, it appears there may be opportunities associated with electroplating (silver and gold finish) various items associated with the sea, e.g. shells, coral, sea exoskeletons, etc.

Is there a course near us we could attend or a useful intro-level reference dealing with plating non-metal surfaces to at least familiarise myself with the process alternatives, safety issues and so on with a view to undertaking limited (electro)plating activities ourselves?

- Sydney, NSW Australia

June 23, 2008

A. Hi, Don. I can't answer your question specifically, but there is an "Australasian Institute of Surface Finishing" and an "Australian Association of Metal Finishers" which probably can. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

November 15, 2008

Q. I am researching ways of electroplating or brush plating canvas. I have sealed the canvas with acrylics and therefore it is non-porous now. I want the effect of a "mirror" but a bit blurry. Is this too costly? Can I silver plate in my studio or is it too toxic? I am open to all suggestions.

Thank you,

artist - New York, New York USA

October 4, 2011

A. Hi, Eduardo.

After your sealing, you need to apply a conductive layer somehow or other before you can do electroplating. Our FAQ, "How do you electroplate flowers, leaves, animal skulls, and other organic materials?" explains the options available to do that. Most silver plating solutions are cyanide based, which is obviously dangerous, but where an exact perfect silver color isn't required, non-cyanide options are available. You can try contacting companies such as EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser] or Zinex for cyanide-free silver plating solutions.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

October 5, 2011

![]() Dear Ted,

Dear Ted,

Thanks for your reply. I will investigate the sites you suggested. I am pursuing more gold electroplating. I have used gold leaf before and it has an impressive reflection except that it is expensive and it only comes in squares of 3" x 3" or 5" x 5". It will take me a long time to cover a big canvas. If you have information on gold plating please forward it to me. I am willing to work with a chemist on this if necessary. The best I think is if I find the right company that will dip the canvas into the gold plating solution holistically and see the results. I am sure there are plants or factories out there that can do this, I just have not found the right one. I have called many but most only work on small items or military and government projects. Thank you again,

Eduardo

- New York, New York USA

October 6, 2011

Q. How can we do chrome plating on cast resin?

Abdusalam Taqi- Kuwait city KUWAIT

March 26, 2012

Q. I want to do plating of resin/fibre idols. I want to do coating of silver, but electroplating normally involves cyanide that is risky. Is there any other way to do coating of silver without using cyanide or any other way which will give the look of silver which is a non allergic durable tarnish or corrosion resistant. What is the process to do so?

San de- mumbai.india

July 2, 2013

A. Hi cousin. The thing is: please don't look for the one single best solution to all problems, because there is no such thing, and you may needlessly lead yourself into very expensive and very complex finishes. If you are simply looking for an attractive, silvery, metallic look for resin articles then "chrome look paint" is very good these days and very practical. It consists of a smoothing base coat, followed by a layer of either tiny aluminum flakes or two-part silvering solution, followed by a clear coat.

Although there are cyanide-free silver plating processes available from a number of sources including Zinex, they would involve metallizing of the resin first (see our FAQ "How do you electroplate flowers, leaves, animal skulls, and other organic materials?") and they would not be tarnish-resistant unless you followed up with rhodium plating or a clear coat. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 2013

Bronze plating resin trophy

Q. Hello. I own a trophy shop in Fort Worth, Texas, and I have a client that wants a prestigious baseball trophy and he loves one that we have that looks bronze, but in fact is resin. Before we go to the trouble and expense of having an artist carve this he wants me to see if there is any way to dip/bronze this resin sculpture of a baseball batter. The size is 15" tall x 14" wide x 5" deep and is a batter in an open stance and the dimensions also include a long rectangular base that the batter is permanently affixed to which would also need to be bronzed. Is there any way to plate a resin trophy like this?

Michael BrandonTrophy Shop Owner - Fort Worth, Texas, USA

April 24, 2018

A. Hi Michael. You have at least two choices, both described on this page. You can metallize the resin and electroplate it, or you can use 'chrome-look paint' with a bronze colored lacquer topcoat. I think you'll find that the latter is good enough if the trophy is kept indoors.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

April 2018

Q. I want to etch an epoxy coating and then sensitize with tin or palladium and then metallize with electroless copper.

So, can you help me about the etching step? what solution do I need for etching?

student - Iran, tehran

June 7, 2019

Q, A, or Comment on THIS thread -or- Start a NEW Thread