-----

Clear coating brass, copper and bronze furniture, sculpture, and jewelry

< Prev. page (You're on the last page of the thread)

Q. I have copper countertops in my home kitchen that I would like to keep shiny and untarnished. The counters get light to normal use, no children in the home, cutting boards always used. They polish up fine to a shiny satin finish using a cleanser with oxalic acid in it but I have not found a clear coat that lasts more than a month or so.

After the clear coat has been applied I only clean with a liquid household cleaner with no abrasive in it but the copper still tarnishes after a few months.

What in your opinion will work the best for me on my countertops?

Thanks, Albert

- Minneapolis, Minnesota

November 6, 2012

A. Hi Albert.

You can try the automotive clearcoat. Because this is a two-part solution that cures rather than dries, it leads to a quite hard surface.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Thank you for the swift response. Is there a particular type or brand you recommend?

Albert Reinhart- Minneapolis, Minnesota

A. Hi Albert. Sorry, we don't print brand recommendations here (huh? why?), but two-part clearcoats don't "dry", they "cure". That is, there is a reaction that occurs when the two components meet. This requires mixing the two components together and spraying/brushing them rather quickly, which is not possible without spray painting equipment, unless you buy the special rattle cans (like the one shown from Amazon) which mix the components just before spraying, or mix them and quickly brush them on. I am not recommending or dis-recommending those special cans, but I don't know any other spraying alternative open to consumers who do not have spray painting systems. I imagine you could brush the two-part coating on though.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I am making in Jaipur India a lot of silicon bronze 15 ft high lamp posts bronze patinated and some gold plate they are going to Israel, 100 yards from the sea, a desert with big temperature swings from night to day, subject to big sandstorms, some ash outfall from a power station.

I thought of E-coating but too difficult to repair, I need a coating that can be stripped off and reapplied on site if necessary.

I thought of a sacrificial wax coating to be applied every year or after a storm -- will wax evaporate in the heat?

Any ideas how we can protect this for 25 years ?

manufacturer - Jaipur, India

June 12, 2013

Q. Thank all you for bright minds information!

~~~~~ Man did I take notes!~~~~~

I am asking a similar question again … :)

Is there a *non-toxic-coating* for *COPPER* jewelry worn on the *SKIN*? … besides the Renaissance Wax?

I did hear of a MagicGloss with decent results. It's only cause it's a NEW 2 yr. Old product for crafts

- Petaluma, California

July 24, 2013

A. Hi Therese

adv.

One of the site's supporting advertisers offers their Protectaclear from Everbrite [a finishing.com supporting advertiser] for that purpose.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I've used Incralac ⇦ on eBay or Amazon [affil link] on my sun-dial and found it barely lasted 12 months before needing redoing. I only used it on the inside of the armorial ring, which is of brass - where the sun's shadow highlights the time. The stand, a pedestal of bronze, has, after 8 years in the weather, acquired a patina of bird droppings, which I've attempted to clean off with only moderate success with soap and water as recommended on another site. Is there a product I could use to protect the bronze in all weathers? I've found Incralac ⇦ on eBay or Amazon [affil link] fine for indoor use but not outdoors. I'm in New South Wales, Australia where the sun can be fairly fierce.

William Power- Terranora, NSW, Australia

November 27, 2013

A. Try Everbrite [a finishing.com supporting advertiser] coating (USA product). Hope it helps and good luck!

Goran Budija- Cerovski vrh Croatia

A. In my experience there is no ideal lacquer, especially not down under.

In regard to the Everbrite coating - I have observed a number of sculptures here in New Zealand where the Everbrite coating has been used. It's not stood up to the harsh sun and UV we have down under.

The Everbrite has dried out, become brittle or cracked and oxidised. Though please note this is also an outcome I have seen with other lacquers.

My suggestion is to use the Incralac

⇦ on

eBay or

Amazon [affil link]

but to regularly clear wax over the top of the Incralac. Re-wax regularly, every 6-12 months. I suggest cold waxing if possible, but heating can be done if very careful.

However my preference is simply to use the clear wax, directly on the bronze, without lacquer, and to simply replenish this wax surface. I have maintained bronze sculptures for years using this simple process (no lacquer involved). Look for a clear wax which has been developed for the Australian environment.

- Auckland New Zealand

March 15, 2023

A. Birds won't go near magnets so add one on each side of the copper or brass bar. Add several close.

JC DREW- USA

June 28, 2023

Q. We have coated some interior polished brass handrails with Incralac ⇦ on eBay or Amazon [affil link] and after 6 months they do not look good anymore, and continue to get worse. They are in traffic areas. The maintenance program is to just dust/wipe the handrails down, no solution or waxes. What can the problem be?

Also, the work area was contaminated by an outside contractor who drilled holes in concrete walls and dust covered all brass, not sure how they cleaned the dust from railings, but could that have caused some deterioration problems?

Dave Nowlan [returning]- St Francis, Minnesota, USA

December 4, 2013

Non-toxic long-life dip for copper-brass valves

Q.

We are making valves (copper pipe brazed into brass body). Our problem is the finishing touch to our products. Looking forward to some non-toxic dipping method which could give good results and good look/finish stays quite long.

product designer - Lahore, Pakistan

May 27, 2014

A. Hi Ali.

" 'Toxic' is a matter of statute, not opinion" as a former New Jersey governor sagely remarked. If these valves will carry drinking water, the brass as well as the coating must comply with standards depending on who will be using them and where. If not, a benzotriazole ⇦ on eBay or Amazon [affil link] dip, followed by a rinse, will last a short while -- but will require brass lacquer for longer tarnish-free life. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hello,

I've just purchased a metal marquee light that should be sealed to prevent the red rust dust from getting everywhere. I've been told to use hairspray or clear spray paint. Can you please tell me if either of those products will work fine or if I should use something else instead.

The light will used indoors only. Also, whatever I use to seal the sign needs to withstand the heat from the lights.

Thank you

Traci

- Atlanta, Georgia USA

July 3, 2014

A. Hi Traci. Clearcoat is not shrinkwrap which you can expect to hold powdery rust in place. If the rust doesn't adhere, although the clearcoat may adhere to the powder, they'll just come off together. So you have to hope that your clearcoat can "wet" the solid metal and adhere to it, holding the intervening rust dust in a suspension. I think your best bet is always something formulated for the purpose (a real clearcoat) rather than something re-purposed (like hair spray).

I don't know what size the marquee lights are, and how much of a heat problem they cause, but maybe you can go retro-modern chic by using LEDs, which won't get nearly as hot :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I have a large Elektra espresso machine about 10 years old. It's made of copper and brass. There is a clear coating that has been damaged by the use of some aggressive cleaning compounds. The machine has surfaces that are heated to greater than 150 °F. I tried spraying lacquer on one of the surfaces that is constantly heated. The surface fogged immediately. Any suggestions for me?

Dan Anderson- san jose California

November 12, 2014

How do I make polyurethane lacquer and acrylic lacquer?

Q. Hey, can anyone please tell me how to make polyurethane lacquer and acrylic lacquer? What is the chemical process for it? Please tell me.

ritesh parmarplating - rajkot gujrat India

November 14, 2014

A. Hi Ritesh. I have no experience in formulating such materials, so I may be wrong …

But I have a whole shelf of books on the topic, and I think you need to get a book on the subject, as I tend to doubt that anyone could answer such a question in a paragraph or two. But we'll see.

Luck and Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Antique cash register (brass/bronze) tarnishes quickly!

Q. Hi … my 100+ year old NCR register is brass or bronze with various surfaces -- smooth, pebbled and decorative motif. It's a beast to clean but even worse, it seems to start tarnishing almost immediately after cleaning. I've never put a finishing coat on it but would like to try something to stem the return of the tarnish. Should I consider a clear spray lacquer? Can this be removed at a later time if desired?

Thanks!

hobbyist - Halifax, Nova Scotia Canada

December 14, 2014

Q. Hello,

I am looking for a lacquer which can be applied to copper (patinated dark), and which can withstand constant immersion in water.

I am making copper vessels that will have water flowing from one to the other constantly. When it is switched off (overnight) it will also have some water sitting in it.

The reason for a lacquer instead of embracing copper natural water resistance is that there is a very particular colour/patination I am after, which would change if unsealed/unprotected.

I look forward to your ponderings …

Many thanks,

Edward

- London, UK

February 25, 2015

To lacquer or not lacquer an antique brass door knocker exposed to elements?

Q. I have a brass "sphinx" antique door knocker that is being professionally sanded and polished right now; the refinishing includes removing copper plating so that just the brass shows. The door knocker will be on a door that is totally exposed to the elements here in New England, and we live about a quarter mile from a bay. I need to buy a new door handle set that will look good in terms of finish with the door knocker. I'm torn between having the antique door knocker lacquered by the professional and then buying a "lifetime finish" on a new door handle set OR instead keeping the antique door knocker unlacquered and buying an unlacquered door handle set so that they hopefully acquire a similar patina over time.

It would help me make my choice to know how long lacquer, if applied to the antique door knocker, is likely to hold up well when exposed to the elements.

One other question--once the copper plating is removed, if I keep the brass antique door knocker unlaquered, what color is it likely to tarnish to? (The copper plating in the past tarnished to a red; as I am going to have a red painted door, my hope is that the brass would tarnish to a different color).

Thank you for any help you can give.

- Bristol Rhode Island

June 3, 2015

Q. Hi

After reading a few US postings mentioning Incralac

⇦ on

eBay or

Amazon [affil link]

(presumably made in the US?), after enquiring upon a UK product called Incralac

⇦ on

eBay or

Amazon [affil link]

(Rylard - claims of military development) and now seeing a German product called Incralac

⇦ on

eBay or

Amazon [affil link]

I wonder if anyone can shed light on this "family" of similarly named and purposed products?

The copper org …

https://www.copper.org/publications/pub_list/pdf/a1349.pdf

Suggests to me that perhaps iIncralac is an "open source" solution developed by interested parties and maybe now manufactured at different locations by different companies?

This is not purely academic as readers cannot be sure as to the universality of recommendations unless we know exactly what product we are talking about.

I take on board Ted's comments about discussing technologies rather than brand names but on this particular thread I do feel it is hard to avoid

@ Ted Mooney

"coating or pretreatment should probably incorporate or be preceded by a preservative like benzotriazole."

Ted, as I understand it benzotriazole forms a passive layer on copper. Do you happen to know whether this layer is compatible with e-coating methods, in particular whether it creates an appreciable electrical insulation that would undermine the e-coating process?

- Ireland (was Denmark)

August 18, 2015

A. Hi Jon. The Incralac ⇦ on eBay or Amazon [affil link] name stems from INternational Copper Research Association LACquer, and it refers to certain lacquer formulas which contain benzotriazole … but that doesn't tell us the formula they developed, nor whether you need permission to formulate it yourself, nor how you get a license to use the name. My suspicion is that it is NOT "open source" but I think you would need to contact INCRA's successor, the International Copper Association to find out. I would assume, although I haven't tried it, that one can dip copper into benzotriazole and then apply a conventional brass lacquer, and obtain rather similar results.

I do not actually know what would happen if you tried to electrocoat a copper surface that was passivated with benzotriazole, but I do know that the compound is used to protect copper masters which are electroformed upon, so I know that conductivity is specifically not a problem, and doubt that there is any problem at all.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. We purchased a statue of Sisters from auction over 20 years ago. We lived in Ca at the time and I noticed some pitting on the arms and decorative areas. We inquired and were told it was due to moisture and to use Lemon Pledge spray. We have and it does seem to arrest partially. What can we do to protect this inside piece of art that will one day be willed to family?

Sylvia miller- Battle Ground, Washington USA

January 18, 2016

A. Hi Sylvia. If it's a really important piece you should contact a metal conservator, especially if you don't know exactly what it's made of. But if that's not realistic, and assuming it's metal not wood, I don't think wood polish is the right stuff. I'd either go with museum wax or brass lacquer. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Clear Coat Failure on Buffed Brass Parts

Q. We rattle can finish our small brass parts that have been buffed to have a satin brass finish. We clean them with acetone

⇦ on

eBay

or

Amazon

[affil link] Flammable!

before we paint them with Rustoleum satin clear enamel. Our little shop processes over 10,000 brass parts a month and we're always fighting with clear coat failure. We experience white haze and cracks. Are we missing an important step? or could it be a temperature or metal expansion problem?

Thank you so much for your insight.

Quality Control - Phoenix

January 29, 2016

A. Using rattle can coating is really never advisable on production type jobs. I had the same issue long ago, I and stopped using rattle cans and started to dip them on more industrial type protective coatings.

Marvin Sevilla- Managua, Nicaragua

A. I have worked in non ferrous metals for half a decade and have researched many options, I have been following this conversation for a few years. So thought I would chime in. I have come across a good reference at

https://www.copper.org/resources/properties/protection/clear_finishes.html

for comparing finishing options for copper and alloys.

I make brass lighting components. The best coating for my application in my experience, is a 2 part epoxy, some parts I have made are sealed by a factory I work with and is very robust and hard wearing and seals with a slight gloss. 2 part applications be it epoxy, acrylic, or silicone etc will have different properties so research what suits you best.

I don't have a dedicated spray booth, so I use Sculpt Noveau clear guard, and its better than the depo bought cans, but is not as tough as the epoxy. If you hit the item with a few coats, it comes out pretty good. Take your time though, as it can cloud over and will need another coat.

Also, surface rust is possible to seal, if its not flaking too much. After sealing it will have a tendency to leech if used out doors, after a good rain, but will 'purge the excess surface rust and the sealer will kick in after a few downpours. 2 part polyurethane is what I used.

I brazed a mild steel rose flower for my now wife while I was studying and sealed it with hairspray, it turned a lustrous black and stopped any further rust and that was 10 years ago! So big fan of hairspray too!

Hope this is of help to someone.

- Sydney, Australia

![]() Thanks for the very informative posting and the excellent link, Ben!

Thanks for the very informative posting and the excellent link, Ben!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I make jewelry and such with various wires. Most of the wire I work with is precoated, but lately I've come into possession of bare copper (house electrical system grade) wire. Perks of remodeling a house. As such, I've started making stuff out of that wire (waste not want not), but I've noticed it tarnishes/oxidizes quickly (my neck stays green). Is there anything I can coat it with that won't wear off after a few days of constantly wearing it? I've tried acrylic coat, and high gloss lacquer coat. Neither work. Any help would be nice and thoroughly appreciated.

Chryssta Lewis- Charlotte Court House, Virginia, USA

June 15, 2016

A. Hi Chryssta. It may be that you just need multiple coats of whatever you apply. But if wear resistance is the single most important property for you, I suspect that a 2-component automotive clearcoat (see my posting of Oct. 8, 2012) , or a UV-cured clearcoat (nail lacquer) will prove more durable than coatings which air-dry like lacquer (and probably your acrylic coat).

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I have tried coating it with the acrylic clear coat, then the lacquer coat (and vice versa), but in a couple days, the coats peel off. Would the nail lacquer (nail polish?) or the UV coat peel after a few days? I should mention that it's moving pieces. There's the pieces I bent and hammered into shape, and the chain links that hold them to the necklace, so when I move, they move against each other. Does that change how the coat must be applied? Would that change what must be used to coat them with as well?

Chryssta Lewis [returning]- Charlotte Court House, Virginia, USA

June 16, 2016

A. Hi Chryssta. Peeling off is a very different thing from wearing off. Peeling off means you do not have proper adhesion, which usually means the article was not truly clean.

You can try very fine sandpaper or brass wool, or scrubbing with a tampico brush and pumice, followed by wiping with acetone. If you can't get to all surfaces you can try dipping into acetone and then allowing to dry, but obviously that doesn't do much real cleaning. In industry, the cleaning of non-scrubbable surfaces could be done via electrocleaning (immersion in very hot and strong caustic soda ⇦liquid caustic soda in bulk on Amazon [affil link] with electricity applied in order to generate scrubbing bubbles of hydrogen), followed by rinsing with water, followed by a dip in dilute sulfuric acid to remove any tarnish, followed by rinsing again.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

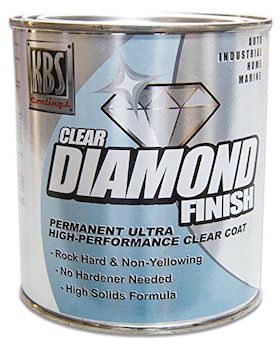

A. KBS coatings make a specialised clear coat for bare metal … it cures extremely hard but remains flexible.

I am about to use it on brass plated motor bike springs.

Gregory Buttle

- tootgarook australia

Q. I have read a lot of the posts in this thread (on polishing brass/copper) and am really perplexed why it is that supplies for finishing/lacquering brass (or any metal for that matter) are so hard to find.

I have spent the majority of today (Friday) trying to locate a supplier of loose cotton, 1/2" thick, 6" dia' buffing wheels and some jewelers rouge

⇦ on

eBay

or

Amazon [affil link] buffing compound as well as brass lacquer. I have found a supply for the Everbrite lacquer (that I have to travel 100km/62 miles by bus and public transport to get to), but I still have not found the polishing stuff in the same area as the lacquer and am quite frustrated that something that I would consider easy to find has become so damn difficult. I live in St Catharines, Ontario, and to get the Everbrite lacquer I have to travel to Toronto, then take public transport to Woodbridge (NNE of the downtown core). I find this quite extraordinary and really perplexing. I can't find anything local that has what I need.

Does anyone know of a supplies business that is in St. Catharines or nearby? Using the internet is no use as I have been unable to source a place close to me. Port Colborne, 40km away by bike, is the closest place that has what I need at the moment, but their prices are excessive.

Which brings me to another point …. 4 oz of Everbrite is $31 plus tax = $37.20!! Why are these products so expensive? I purchased some rusto-leum (?) clear varnish (oil based) from Canadian Tire which I took back, because I felt it wouldn't last too long, which is why I have gone on the search for something better. But that product was 960 ml and cost $15 + tax = around $18.

The brass pieces I am trying to lacquer need a durable finish.

These were all made by me on a milling machine or lathe.

Any help would be appreciated.

- St Catharines, ON, Canada

September 30, 2016

A. Hi Christopher. Even common things like clothes are getting very hard to stock and sell from brick & mortar stores. Macy's is closing numerous stores, so is Sears, so is The Limited. There is one major mall under construction in all of America, and that one is only being built because local governments have promised ludicrous & outrageous tax breaks. It's changing times; everything you want is readily available on line though.

I certainly don't fault you for returning a product you felt inadequate, but time is money and people have to be paid; so the products we buy have to be priced high enough to absorb the time spent on the original sale, the cost of the wasted product, the time spent on the return, the containers & packaging, shipping, commissions, etc. Things can't be sold at cost, and allowance must be built in for returns, liability insurance, etc.

Similar to other products, buying 16 ounces halves the cost per ounce, buying a quart reduces it further, and by the gallon it's about $2 per ounce rather than $7.75. If you contact Everbrite [a finishing.com supporting advertiser] directly to buy in volume you'll find that it's probably even less if you needed a 5-gallon container. Best of luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hello, I'm looking for a clear coating solution for a range of polished copper bathroom accessories, such as a towel rail and wall hook. One of the products is a toothbrush holder will sit on the countertop, so this will likely sit in water sometimes and be exposed to toothpaste as well.

In terms of durability and water/humidity resistance, Ted's advice on this thread seems to point to 2 step automotive coatings. From reading about some of the more professional ones, I understand that they are primarily urethane based, is that right? The information on their websites is not quite clear in this regard.

From what I'm reading from the Copper Development Association's site, it would seem that acrylic or epoxy based products could offer the best performance. I understand that everything depends on application and environmental conditions. (I wish someone would do a double entry chart on this with performance ratings in each evaluation category depending on application and conditions). Is it possible that some 2-step automotive clear coats are actually acrylic or epoxy based?

In terms of application, my coater as well as these automotive coating websites recommend a light sanding or wet sanding prior to application. While the automotive folks are obviously thinking over paint, I imagine the same thing applies to copper, and perhaps even more so to achieve proper adhesion. Does this mean my polished copper finish is out the door? Or what level of sanding are we talking about? Is there an alternative, i.e., chemical etching or something else?

If anyone has long term experience with such automotive clear coats on copper, I'd very interested in getting an idea of durability after a few years, and the necessity and relative difficulty of reapplying.

Sorry for the long post. Look forward to replies, thanks!

- Montreal, QC, Canada

November 30, 2017

A. Hi Patrick,

Clear acrylic gloss or high gloss lacquer may be helpful for your application. Sanding helps improve adhesion by increasing the surface area but sanding is not required.

Blake Kneedler

Feather Hollow Eng. - Stockton, California

![]() Thanks Blake. I've since ordered a urethane acrylic that's designed to work over a range of raw metals from one of the major producers of professional automotive products. Not cheap, but supposed to work fine without sanding. Will keep you posted on results.

Thanks Blake. I've since ordered a urethane acrylic that's designed to work over a range of raw metals from one of the major producers of professional automotive products. Not cheap, but supposed to work fine without sanding. Will keep you posted on results.

- Montreal, QC, Canada

December 30, 2017

Q. Hi all, I make jewellery and metal art from Silver, Copper and Brass (so far never mixed; these are just the three materials I generally use) and while I have tried many things I can't seem to find anything that works.

I've tried the Renaissance wax with a pre-treatment of baking soda [in bulk on

eBay

or

Amazon [affil link]

and water, and that works super well on silver but not so much on the brass and copper (they still dull and darken over time)

I'm now looking to create a very particular piece - a jewellery box with brass designs inlaid into the surface. These will be fixed so can't be removed for touch ups, etc., as the wood used (tulip if it matters) will be sprayed and I'm afraid of a reaction to the spray if I apply it in place. Additionally, Malta is a very humid and dusty country so this will need to be dusted (and probably wiped with a damp cloth) from time to time and there might be some light wear since it is the cover of the box.

Similarly I am making a set of bookends with brass rod elements and need something to cover these as well.

Basically I'm looking for something permanent that could survive a nuclear attack.

Any help would be appreciated.

- Malta, Europe

March 28, 2018

A. Try Everbrite [a finishing.com supporting advertiser] coating or, if you are rich man, try nanotechnology based coatings (1000 euros/1 lit!!) …

Hope it helps and good luck!

- Zagreb,Croatia

April 5, 2018

Q. I have some pathway lights that have a copper-like coating. I think the base is aluminum. The finish on the first batch started to come off pretty quickly, probably due to chemicals in our water which was splashing the lights from the sprinkler system. I got some new lights eventually and tried spraying them with some clearcoat, but I think the solvents in the clearcoat ate into the copper-look finish. Any suggestions for things I could try? Maybe I should have just shelled out for real copper lights to begin with, but couldn't find any pagoda-style lights.

Rob Hulvey- Los Angeles, California, USA

August 28, 2018

A. Hi Rob. You are probably right about sprinkler water being more corrosive than rain water or city water. Chemicals like lawn fertilizer can be a problem. I think you realize the problem here: you have something which looks like copper but isn't, and you don't know what it is. But the thing is, we readers probably don't either :-(

It might be anodized aluminum with a copper color dye, or it might be a paint or powder coating. My guess would have been anodized aluminum, but I wouldn't expect solvents from a clear coat to react with anodized aluminum.

At this point I'd probably suggest that you look for an outdoor spray paint (like Krylon or Rust-oleum) in a copper or other hammered metal look, and apply it after cleaning the lights the way you would clean dishes.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. I treated a copper weathervane with Incralac

⇦ on

eBay or

Amazon [affil link]

and it may last ten years according to one of the posts here on this, however, I had hoped for longer. I am not keen on the wet shiny look it leaves.

It's fine for a weather vane which is far out of sight. I treated a copper watering can and a plant container and neither has tarnished but these are indoors.

I am considering using it now on an external bronze bell which has a nice patina I am hoping to keep; I fear it might lose its patina using the lacquer again and the permanent "wet" look is not that desirable. I read that the natural patina on outdoor copper and bronze items does in fact itself protect what's underneath from further deterioration so best to not treat it with anything at all?

So I am tempted to leave it untreated, but does anyone with experience agree that this is true?

- United Kingdom

November 10, 2018

A. I would like to suggest trying the Satin or Matte Incralac ⇦ on eBay or Amazon [affil link] coatings. They are not glossy and it is better than regular Incralac ⇦ on eBay or Amazon [affil link] in preserving a natural metal look.

Marvin Sevilla- Managua, Nicaragua

A. Try USA made nanotechnology based protective coating (www.nanotechcoatings.com/automotive-coatings/metal-coating/ ). Hope it helps and good luck!

Goran Budija- Zagreb,Croatia

Ed. note: We thank Marvin for many great postings, and Goran has helped our readers with an incredible 1200+ responses across more than 16 years, so we posted those replies -- but we do ask that specific brands and sources not be suggested ( huh? why?)

Q. We are looking for a suitable clearcoat for polished brass and copper to seal our bathtubs. As the coating will be exposed to regular warm water several manufacturers site "milkiness" as a potential problem yet I feel there must be a solvent based coating that can work.

I understand that powder coat technology has now moved forward and low temperature clearcoats are possible.

Does anyone have experience with such coatings?

Principal - Birmingham (U.K.)

June 27, 2022

A. Hi Romuald. Automotive clearcoat withstands car washes, and blistering sun followed by rain ... I think it's well worth a try. But I think it should probably be proceeded by a proprietary benzotriazole dip.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Try nano technology based coating for metals (www.metaliercoatings.com/uk/what-is-metalier/extras/metal-clear-coat/). Hope it helps and good luck!

Goran Budija- Cerovski vrh Croatia

.

Q, A, or Comment on THIS thread -or- Start a NEW Thread