Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

DIY brush plating of automotive parts

1995

Q. Hello. I was at the SEMA auto show and there were several companies selling a brush plating set-up. The prices varied wildly! Is there a simple way to home-build one of these? I am not interested in doing this as a full time business, only on some of my own items I sell at the swap meet. It would be nice if it was portable. Thanks for your help. Chris.

Chris Morley1995

A. Hi Chris. One thing to realize that may help you understand the price gap is that of all plating jobs, the one "easy" one is gold plating car emblems -- so this is what they will usually demonstrate at shows. And it can be done with even very cheap kits.

The reason it's so easy, besides the fact that the emblems are small, is that 99% of the work has already been done for you. You are starting with an item that already has a very high quality OEM copper-nickel-chrome plating job on it, 99 percent of which you'll leaving just as is :-)

All you're doing is removing a few millionths of an inch of chrome plating from the top and replacing it with a few millionths of an inch of gold, relying on the beautiful, perfect, corrosion resistant, pre-existing, heavy copper-nickel plating to deliver the shine.

So the polishing, the buffing, the cleaning, the activating, the copper plating, the semi-bright nickel plating, the bright nickel plating (all the hard stuff) was already done for you! If all you want to do is replace the chromium topcoat on previously plated parts with gold, there isn't much to it, and probably any cheap equipment will do.

But when you start from raw metal (like a carburetor, manifold, or mounting bracket) plating is not nearly so easy :-(

A lot of technical knowledge is required to deposit plating that will resist corrosion, not peel off, and be attractive. It's usually many layers of different plating. For starters you need to know the metallurgy of the parts to be plated (you need specialized prep cycles to plate zinc diecastings, aluminum, stainless steel, cast iron, or previously painted or plated parts). It is certainly possible to do quality brush plating, but some of the cheap kits and chemicals you see mass marketed, and the techniques suggested, will produce junk if you're not starting with a part that's already well plated.

Some of the chemicals required for plating are dangerous, aggressive, and regulated; and you may theoretically need a license, although I've never personally heard of the EPA actually bothering home platers. But buying the right chemicals may be a problem because some sellers are concerned about their liability in selling dangerous chemicals to an unlicensed facility.

You may wish to buy or borrow the book Electrochemical Metallizing by Marv Rubinstein, which is the bible of brush plating, or to contact manufacturers of quality brush plating equipment. Best of luck!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

RFQ: I'm looking for a small, low cost kit to e-plate small brass items with gold and silver. Preferably non-cyanide, brush and/or dip coating. A UK supplier would be ideal.

Any suggestions?

- design, U.K.

1996

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

A. Hi, Pat. Please see the ad banner near the bottom of the page for brush plating stuff. Sorry, we share tips and technical info here, but we don't post recommendations of suppliers in the forum, we only list supporting advertisers.

Cyanide has been the standard for silver plating for a hundred years, and a century later I think you'll find the color of non-cyanide silver to be very slightly "off", but for personal use it may be fine.

adv.

Try EPI / Electrochemical Products Inc. [a finishing.com supporting advertiser] or Zinex for non-cyanide silver. Non cyanide gold is common, with a choice of vendors.

Please remember that "there's plating, and then there's plating". To get a very thin, reasonably bright layer of silver or gold on a polished brass surface isn't all that difficult. But to plate on a rougher substrate, and to insure that you have true metallurgical bonding and a durable coating that won't quickly peel or wear away, and a non-porous deposit that will retard corrosion instead of accelerate it, and that the gold or silver won't diffuse into the brass, is a bigger challenge.

Please see our "must have" book list if you would like to know about some plating books.

If just a thin re-plating of silver is needed, a wipe-on silvering solution may suffice without any need for electroplating. Please see our FAQ "Silver Plating at Home"

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

RFQ: Looking for small electroplating brush kit to finish small parts up to antique electric lamps. Copper and Brass are most needed.

Fred B [last name deleted for privacy by Editor]antiques and hobbyist - Palmyra, Pennsylvania

2003

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

RFQ: I am interested in a portable Cadmium Plating unit. I used to have one that had a small 12 Volt Battery and we got the solution from I know not where. Thank you.

Louis M [last name deleted for privacy by Editor]Helicopter Re-Building - Eugene Oregon USA

May 19, 2011

Ed. note: This RFQ is outdated, but technical replies are welcome, and readers are encouraged to post their own RFQs. But no public commercial suggestions please ( huh? why?).

Hi Louis. Please see the banner near the bottom of the page. You already know it, but for the benefit of other readers who might jump to wrong conclusions: cadmium plating is reserved strictly for aerospace use these days where the specs call for it. Cadmium is a bioaccumulative toxin we are all working hard to eliminate.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

December 12, 2012

To view current RFQs for brush plating equipment and supplies and other metal finishing equipment, or to post your own RFQ, please see "Seeking Products and Services for Plating Shops"

adv.

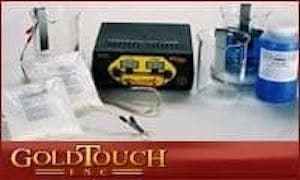

Brush plating equipment, chemicals, and supplies from Gold Touch

Q, A, or Comment on THIS thread -or- Start a NEW Thread