Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

ASTM D3359 Standard Test Method for Measuring Adhesion by Tape Test

Q. What is the spacing of the cuts required for this ASTM Adhesion Tape Test?

Thanks,

Sonia Lai- Bloomfield, Connecticut, USA

2001

|

|

A. Sonia, I believe you are referring to Method B within ASTM D3359. If so, the spacing between the cuts varies with the dry film thickness of the coating. For coatings with dry film thickness of up to and including 2 mils, the spacing is 1 mm apart, with eleven cuts total (unless there is another agreement). For coatings between 2-5 mils, the spacing is 2 mm and six cuts. For thicker coatings, Method A is recommended (an "X" cut procedure). Roy NussTrevose, Pennsylvania, USA A. Hello Sonia! >From Paragraph 12.2.1- "For coatings having a dry film thickness up to and including 2.0 mils (50 microns) space the cuts 1 mm apart and make eleven cuts unless otherwise agreed upon." >From Paragraph 12.2.2- "For coatings having a dry film thickness between 2.0 mils (50 microns) and 5.0 mils (125 microns) space the cuts 2 mm apart and make six cuts. For films thicker than 5.0 mils use Test Method A (X-Cut Tape Test)." Good luck!  Lee Gearhart metallurgist - E. Aurora, New York |

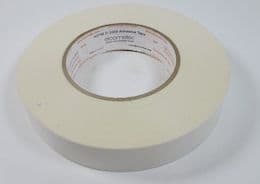

Q. AFTER FOLLOWING THE PROCEDURES FROM ASTM D3359 B, WHAT TYPE OF TAPE DO I NEED TO USE AND HOW MANY RUBS DO I HAVE TO TAKE AND AT WHAT ANGLE DO I NEED TO PULL THE TAPE?

CESAR H. MARISCALINSPECTION COMPANY - Shanghai, China

2006

Q, A, or Comment on THIS thread -or- Start a NEW Thread