Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Anti-Oxidation / Anti Electrolisis

2001

To whosoever knows,

I need a product that will perform at least two jobs at the same time.

A. An anti-fouling paint for a brackish and salt water 5052 and 5086 aluminum boat .

B. An anti-oxidation / anti electrolysis system.

About "B", since zinc is traditionally used as a an electrolysis sacrifice, will the zinc in zinc chromate not sacrifices as well? Additionally, if sacrificial zinc bars are affixed to the hull, engines, etc., and then coated with zinc chromate will the sacrificial effect of the attached sacrificial bars be lost?

If the hull should be left bare to contact the sacrificial bars, and or the bars themselves then also left uncoated, what is the point of anti-corrosion protection with any coating at all?

If the hull and engined are unprotected how severe will the electrolysis attack be on aluminum with dc generators running all night, and 120v ac battery chargers and 120v.shore power at night be?

Who markets a protection system we can use effectively?

George LongLong Gone Boat Charters - Baton Rouge, Louisiana

These questions are best referred to an international corrosion information society (organization) called NACE, available on their website of that name.

W. Carl Erickson- Rome, New York

2001

2001

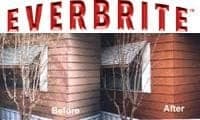

You may want to look at Everbrite Protective Coating. It is a non conductive clear coating that will protect the aluminum from salt water, corrosion, oxidation and other damaging elements. It is a clear coating that can be sprayed or wiped onto a clean surface.

Hope this helps,

Teresa SedmakEverbrite Coatings

Rancho Cordova, California

2001

Hi George

If you do have sacrificial bars, then yeah you would have to leave them exposed. However it could well be that in the environment you describe, the aluminium hull could corrode to protect the zinc. Aluminium is after all a very active metal.

The aluminium will corrode to protect the, basically iron, engine. Leaving the generator on will certainly help, whither it'd be enough is down to many factors - you don't get an even distribution of current around the hull. And even with not being in contact with other metals some areas will have higher corrosion potentials than others, and you'll get corrosion that way. However you aren't the only one with this situation, ask other boat owners or chandlers what they use.

If there isn't some ready made paint/lacquer, then it's time somebody mixed one up.

Ian Brookeuniversity - Glasgow, Scotland

PROTECTION AS AN ANTIFOULING IS AVAILABLE FOR YOUR ALLOY BOAT. LEAVE THE ZINC ANODES EXPOSED AND IN CONTACT WITH THE ALLOY HULL. ENSURE THAT YOU USE A COPPER FREE ANTIFOULING. SPRAY INTERNAL SURFACES AND MOTOR WITH A CORROSION INHIBITING COATING TO SEAL.

STEVE BEAUMONT- NEW ZEALAND

2002

I have a 34' Striker, An aluminum boat. I paint the bottom every spring with Alumiguard a tin based antifouling paint designed for aluminum hulls, it's made by Pettit. I also have an auto electrolysis system and galvanic Isolators to protect against stray current, And a hull potential meter to let me know what its protected value is at all times. All this might sound like a lot but it's a must for for any high end aluminum hull. I hope this was of some help

Arthur Sommer- Bayshore, New York

2002

----

Ed. note: We believe that tin based paints are no longer allowed for environmental reasons due to the toxicity of organotins.

Q, A, or Comment on THIS thread -or- Start a NEW Thread