Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Galvanic Compatibility of Aluminum and Copper

< Prev. page (You're on the last page of this topic)

Q. I have a client that wishes to purchase a copper rain chain that will be draining water out of an aluminum gutter. I typically dissuade my clients from doing so due to electrolysis. However the website where the rain chains are advertised says it is not a problem as long as you do not put them in direct contact with each other which seems like it would be difficult since the attachment piece needs to be placed inside the gutter. They advised to spray clear lacquer or piece of plastic underneath attachment piece. I wish to get a second opinion concerning this matter.

Nadia Crowther- KYLE, Texas US

September 28, 2016

A. It's true that dissimilar metal corrosion can be stopped by insulating one metal from the other, but you need to be sure of the disconnection. If you were sure that an insulator between the metals is good, then this would work.

So the chain cannot be electrically connected to the rain gutter. Perhaps a plastic link between?

Geoff Crowley

Crithwood Ltd.

Westfield, Scotland, UK

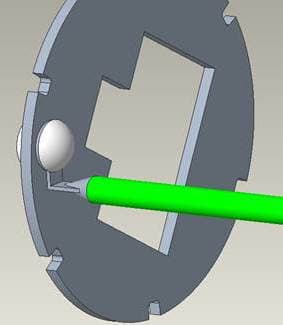

Q. I am looking to make a thermoelectric (Peltier) system where the peltier chip is cooling a block of copper. Then an aluminum rod that is hard anodized will be threaded into this block using thermo paste.

I am doing this two piece design because copper is not food safe but has a very high thermo conductivity. I want maximum thermo transfer and effectiveness of the Peltier chip. ie, get that aluminum rod as cold as possible. The aluminum piece will be submerged in beer to chill the beer. That is why the aluminum is hard anodized, to help with the food safe-ness. This is long term storage (1-2 months max at a time)

The copper will never touch the beer, only most of the aluminum will.

My questions are:

1. Even with the hard anodize, and the thermo paste between them (Though not perfectly distributed), and the copper not being in contact with the beer. Is there a plating or anything I can add to the copper to slow or even stop that galvanic corrosion on the aluminum? Since cost is a factor, what is the second thing I can do?

Example, I am assuming the best answer is to plate the copper with maybe Silver or something. Is the second best option to plate in Nickel? Something that is presumably less expensive?

2. If there were a way to make copper food save via plating of some sort or what have you, and I could make the whole thing out of copper (Likely expensive btw), what plating or treatment might that be?

Thank you

Kelly

- Burnsville, Minnesota

October 19, 2016

A. Hi Kelly. We'll see if anyone else has a second opinion but I don't foresee any galvanic corrosion at all because hard anodizing is an excellent electric insulator.

However, you might want an o-ring to make sure your thermal paste doesn't get into the beer. And you might want to tin plate the copper because lack of galvanic corrosion does not guarantee lack of corrosion.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Aluminum saildrive is pitting; is copper bottom paint the problem?

I use copper based antifoul paint on the hull of my sailboat. At the end of season I see pitting on the boats aluminum lower saildrive unit and the aluminum prop. I use magnesium anodes, and they show significant galvanic reaction. What do I need to do to reduce the pitting on the aluminum saildrive and prop?

P.S. the boat is used in a fresh water lake.

Rick

- Orillia ON Canada

November 15, 2016

A. Hi RA. One necessary step is to make sure there is no metallic connection, if that's possible to arrange, from the copper-based paint to the aluminum because that would definitely cause galvanic corrosion.

Antifoul paint is often deliberately ablative; but whether that actually means in practice that the aluminum is going to find itself surrounded by copper ions that cause it to pit, I don't personally know. Can you consider painting the aluminum saildrive and prop (not with copper based paint!), or is that a problem?

BTW, I didn't think ablative paint was required in fresh water in most cases, although low copper content paint is used :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. The aluminum prop and saildrive leg are annually cleaned up and painted with OMC zinc based primer and marine enamel.

The pitting problem persists. The copper anti-foul paint is not applied to the aluminum parts.

Here is a photo of the saildrive leg showing the pitting. The prop has similar pitting.

RA Swinton [returning]- Orillia ON Canada

A. Hi RA,

I'm sorry to hear of this problem. I agree with Ted and there are many possibilities to investigate. Priming and painting pitted parts as depicted in the photographs is dicey at best. Much prep work such as sanding is needed and the first layer of primer needs to be applied deeply into the pits if possible. Additional primer coats are likely needed. Apply primer in a dry environment. The primer must not be left on the parts for a long time without the top coat application. Top coat should be applied immediately after final primer coat is sanded and cleaned.

Blake Kneedler

Feather Hollow Eng. - Stockton, California

![]() Thanks for the input information.

Thanks for the input information.

I will be cleaning and refinishing the aluminum saildrive leg and will apply less copper based anti fouling paint in the vicinity of the saildrive leg.

I also plan to add more magnesium anodes to increase the effective surface area for sacrifice.

- Orillia, ON Canada

Q. Good morning

On an algae-resistant shingle roof (partial copper granular) that drains into an prefinished alum. .032" gutter, should I be concerned with galvanic action?

Is there a corrosion possibility from the rain run off-from a copper roof into a prefinished alum. .032" gutter ?

cass - Detroit, Michigan

May 30, 2017

A. Hi Ed. Most of my roofs seemed to lose granules, which collected in the gutters. If a significant number of these granules were copper rather than aggregate, you certainly have the potential for corrosion of the aluminum. However, in your favor is that rainwater is highly non-conductive, and that the surface area of copper granules should be quite small compared to the surface area of the aluminum. I think there is a possibility of pitting of the aluminum but little likelihood of it actually being a problem. But guesses aren't the equal of experience, so you should see if any evidence-based white papers on the subject are available. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Aluminum gutter pinholes

Q. I have a problem with corrosion on aluminum 10 year old gutters. I live on the water in Oceanport NJ. Recently we noticed corrosion on some of our gutters on our home we built in 2006. The outside bottom of some of the gutters have large areas of corrosion showing through the finish paint and many pin holes.

The only copper we have is flashing, but a gutter company I spoke with says the salt water air (we are directly on the water) is reacting with the runoff from the flashing to form a battery and causing the corrosion. The corrosion is happening on a few but not all our gutters.

I would think that the aluminum in some of the gutters is faulty and not related to our location, etc.

Thoughts?

Home owner - Oceanport, New Jersey USA

June 16, 2017

Q. I have a brass component coming in contact with aluminium. I understand this will cause galvanic corrosion between the two. Will Nickel plating on the brass component prevent the same?

Mihir Bajekal- Mysore, Karnataka India

October 12, 2017

A. Hi Mihir. Nickel plating won't help much, but Chris Snyder says tin plating will help significantly and I believe he is right on.

Please take the time to provide the full details of your situation for better, more enthusiastic answers. Thanks!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have an old outboard motor with a 1/4" threaded brass plug in the aluminum lower unit. The plug is used to fill the lower unit with grease. It's been in there a while.

When I tired to remove it, the plug is frozen in place. Is there an oxide or other material formed between the brass and aluminum that could possibly be dissolved with a liquid solution? or do you have any suggestion as to how to remove the plug? It's the slotted screw that is now stripped.

Curtin marina - Beverly, New Jersey

February 18, 2018

A. Hi Matt. Aluminum is a great material in a lot of ways, but aluminum threads are a misery. I've hacksawed aluminum hose fittings off of brass bibs, struggled with snips and pliers getting old bulbs out of lamp sockets, put an aluminum key into a lock with aluminum pins, instantly rendering it non-removable.

You can try WD-40 ⇦ this on eBay or Amazon [affil links] 'ing and patiently tapping for 5 or 6 days, but I think you'll end up drilling out the brass and re-chasing the threads in the housing. There are theoretically some special acids (chromic-phosphoric) that can dissolve aluminum oxide without much damaging aluminum, but I doubt that you'd find it practical, and chromic acid is a toxic carcinogen you may not even be able to buy anyway.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Ted, thanks for the answer. That was exactly what I was hoping for. Fortunately my retired mechanic came by and we put heat from a torch on the aluminum around the brass plug, and used an impact screw removal screwdriver to carefully and slowly unscrew the plug.

Ted, thanks for the answer. That was exactly what I was hoping for. Fortunately my retired mechanic came by and we put heat from a torch on the aluminum around the brass plug, and used an impact screw removal screwdriver to carefully and slowly unscrew the plug.

But I'll remember your aluminum oxide solvent for next time. Thanks again. And if you're ever near Burlington, stop in our restaurant on the river and I'll buy lunch.

Curtin marina - Burlington, New Jersey

Glad to hear it, Matt. I have heard of using heat, but if I had thought of it I'd probably be a bit afraid to suggest it in a unfamiliar circumstance. Dutch Treat would be fine -- I really need to get a map and some stick pins and plan a road trip to visit the people I "meet" here :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. There was a thread that wasn't answered previously about copper tubing and aluminum fins. I want to understand why there is such negative marketing for metal (copper/aluminum) solar pool panels. I have 4 very small pin hole leaks after 20 years ( I had to remove to replace my roof) but was told they may have been created due to the panel freezing and not draining. All 4 pin holes are all just about equally in the middle of the tubing. Every company I've talked to in San Diego, Orange,LA and Riverside County will only install this plastic stuff. BTU transfer per square foot is pretty pathetic and expensive for what you get to boot. I'm really not convinced metal is not the best material to use.

Mike Root- LAGUNA NIGUEL, California

March 5, 2018

A. Hi Mike. Countless thousands of miles of aluminum-finned copper tubing has been used for baseboard heating in homes, and on home air-conditioning compressors and evaporators. If your roof-top heater lasted 20 years it's understandable that you prefer a metal replacement rather than a plastic unit.

I know nothing of this subject, but googling produced Sun Ray Solar in El Cajon as a supplier of copper/aluminum rooftop pool heaters.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() That is only one I found and he manufactures, doesn't install. I had to reinstall my old panels myself with a friend. I plan on using his panels in the near future. Just curious technically why this is such an issue. Maybe I'm just a little tainted but it seems like shipping costs and profit margins for the plastic material is the driving factor. I'd have to cover my whole roof with plastic panels to get the same BTU transfer as from the 9 copper/aluminum panels I have now. I'm sticking with metal. Thanks

That is only one I found and he manufactures, doesn't install. I had to reinstall my old panels myself with a friend. I plan on using his panels in the near future. Just curious technically why this is such an issue. Maybe I'm just a little tainted but it seems like shipping costs and profit margins for the plastic material is the driving factor. I'd have to cover my whole roof with plastic panels to get the same BTU transfer as from the 9 copper/aluminum panels I have now. I'm sticking with metal. Thanks

- Laguna Niguel, California

Q. We have installed aluminum doors over copper door pans separated by a bituthene membrane. Is there any chance of corrosion if the materials are separated?

Thanks

- Carmel, California, USA

February 27, 2018

A. Hi Alfred. Galvanic current cannot flow through an insulating membrane, so you will have no galvanic corrosion. But all non-precious metals, including aluminum, corrode eventually. Presumably the door is anodized, clear coated, or powder coated to forestall corrosion.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello, I have been asked to design a bird feeder for university I am planning on making mine out of Copper and Aluminium. I will be using plastic o-rings and washers to screw the pieces together, will this be okay to do so? So long as the Copper and Aluminium is not touching one another in any way?

Thank you.

- Kansas City, Missouri, United States

March 14, 2018

A. Hi Sean. Right, you cannot have galvanic corrosion between the two metals unless there is a metallic path between them to carry an electrical current.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hello, I have a 6061 Aluminum cooling channel that has an OFHC 101 Copper plate fastened to it. Water is typically used as the coolant. I am seeing degradation of the aluminum. It would be difficult to coat the copper plate so can someone recommend a plating on the aluminum to keep it from the galvanic corrosion.

Mark Bernick- Duquesne, Pennsylvania, USA

September 6, 2018

A. Hi Mark. Aluminum can be zincated then copper plated, which should minimize or eliminate any galvanic reaction.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Thanks Ted, I will give that a try.

Thanks Ted, I will give that a try.

- Duquesne, Pennsylvania USA

Q. I, mistakenly, wrapped aluminium foil tape on copper pipes for insulation (the pipes carry hot and cold water). Apparently, that won't insulate it one jot! I'm now going to lag the pipes with recommended foam lagging. Can I lag over the existing aluminium coating or should I take it off (painstaking to do as it's well glued on). If I don't take the aluminium tape off is there a risk of galvanic corrosion of the copper pipes?

Syed Gilani- London, England, United Kingdom

November 20, 2018

A. Hi Syed. The aluminum foil was no help, but I don't think it will be a hindrance. Aluminum is so active and copper so noble that I would not expect the aluminum foil to hurt the copper at all.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Huge thanks for the prompt reply Ted, enormously appreciated :-)

Huge thanks for the prompt reply Ted, enormously appreciated :-)

- London, England, United Kingdom

A. The only way copper can be corroded by galvanic corrosion is if it comes in contact with a metal more noble then itself, for example Siver and Gold, Aluminum is one of the more reactive metals one can find in the construction industry, even when it develops its protective aluminum oxide layer. This means that if any galvanic coupling is created (metals coming in contact with each other) Aluminum will act as a sacrificial anode and copper will be protected.

Marvin Sevilla- Managua Nicaragua

Q. I am John in Overland Park, Kansas and plan to use uncoated 1/2" diameter aluminum rods as balusters on deck rails made of cedar-toned treated lumber. Will the corrosion of the aluminum rods be severe enough to cause a problem?

John Bosnak- Overland Park, Kansas

March 21, 2019

A. Hi John. I don't think it's a good idea. Untreated aluminum is not a very decorative or corrosion resistant finish. And though I'm not sure exactly how the high copper content in the treated lumber will leach onto the adjacent aluminum or interact with it, it can't be good :-(

If you search the site for "clearcoat aluminum" you'll find several very good dialogs on the subject. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

|

|

Q. Thanks for the information about corrosion of aluminum balusters in treated lumber. Would 304 stainless steel balusters provide sufficient corrosion resistance to treated lumber (cedar-toned treated southern pine) or is 316 stainless steel required? - Overland Park, Kansas March 27, 2019 A. Hi John. You'll find all sorts of outdoor stuff made of each. We can say that 316SS is better, but it's hard for anyone to say whether 304SS will please you or you'll wish you went for 316SS. Probably more important than the material is to make sure it's passivated. Please search the site for passivation of stainless steel and continue the discussion on an applicable thread if you wish ... we shouldn't let threads about galvanic compatibility between aluminum & copper wander into procedures for passivation of stainless steel or nobody will be able to find anything :-) Regards,  Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey |

Q. Hi,

I'm a computer hobbyist wanting to fashion a custom aluminum bracket to mount a nickel plated copper heat sink to a GPU (temperatures won't pass 80 °C). I've read multiple threads saying to not mix aluminum parts with copper based parts however, this has all been regarding a water cooled system.

The aluminum will not be in between the heat source and the base of the heatsink

Will an aluminum bracket in contact with Nickel plated copper at ~80 °C in dry conditions corrode?

Thanks!

- Los Angeles, California, USA

May 10, 2019

A. Hi Ricardo. You can't have galvanic corrosion without an electrolyte (a conductive liquid).

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have copper flashing and valleys on my roof, installed AFTER I had installed a few galvanized metal gutters and downspouts .. I KNEW what would eventually happen but thought I could afford to replace them with copper gutters and downspouts... Well the time has come and I can't afford the copper... will aluminum last longer or will that react, too, and destroy the much thinner aluminum?

Jerry MillsMilzarch LLC, restoration architecture - Sanford, Florida, USA

June 10, 2019

A. Hi Jerry. Neither aluminum nor zinc is compatible with copper, but painted aluminum ought to be inexpensive and last a reasonable time.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Hi Jerry,

Have you considered a physical insulating barrier between the two metals where they touch, such as a strip of semi-rigid plastic, in case there is any abrasion and the paint scrapes off the aluminum, or the aluminum is only painted on the outside? Also, can you use nonmetallic fasteners such as Acetal bolts if you are joining two dissimilar metals? You should read up on the strategies they've used on the Statue of Liberty restoration; it's pretty neat. As I recall, PTFE-sealed bolts and washers are involved, with the intention of breaking any possible electrical conductivity that can lead to corrosion.

Rachel Mackintosh

lab rat - Greenfield, Vermont

A. Hi Rachel. For many applications I think your solution will work, but copper roofs usually have copper actually running off of them, as we can see from the green stains. I think the copper salts/oxides will be in the runoff and in the gutters.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Iron phosphating a copper tube with aluminum fins

Q. A copper tube and aluminum fin used in a heating system similar to baseboard is to be pretreated in a iron phosphate conversion 5-stage wash system. I assume that this will cause a galvanic reaction. Is there likely to be any negative consequence to the wash system or wash chemistry?

Taidgh BuckleyHVAC Manufacturer - Westfield, Massachusetts, USA

December 12, 2019

A. Hi Taidgh. Please try to give us the whole story so we can help you best, rather than an extract covering a single step. Originally I simply wrote that I agreed with you that iron phosphating a copper-aluminum item sounded like a bad idea to me as well ... but then I realized the possibility that maybe you want to do this iron phosphating step because you are considering e-coating the coil assembly? In that case, yes, you must pretreat the aluminum.

I don't think putting a copper and aluminum article into a 5-stage iron phosphate line will seriously contaminate the process, but I'd need to see the tech data sheets from the process supplier to be confident about it. Sometimes there are chemicals put into a process to optimize it for a particular application which are inappropriate for a more general application. The phosphating process can and should be optimized for processing aluminum :-)

(Readers: Using the google search term "aluminum-fin copper corrosion" produces a good deal of interesting papers covering theory, practical solutions like pretreating the aluminum vs. e-coating the assembly, and the use of corrosion preventative compounds for this particular application).

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Ted, thank you for your response. This particular product is a copper tube with an aluminum fin that are both attached to a cold rolled steel frame. Unlike a typical fin and tub heating element these are not enclosed and will be powder coated, which is why they are being pretreated. The components must be assembled prior to powder coating. Unfortunately, I cannot provide the wash chemistry as it is all listed as "trade secret" on the data sheets. I will reach out to the supplier to see if they have any reason to suspect an adverse effect of washing these materials together. Thank you for your assistance.

Ted, thank you for your response. This particular product is a copper tube with an aluminum fin that are both attached to a cold rolled steel frame. Unlike a typical fin and tub heating element these are not enclosed and will be powder coated, which is why they are being pretreated. The components must be assembled prior to powder coating. Unfortunately, I cannot provide the wash chemistry as it is all listed as "trade secret" on the data sheets. I will reach out to the supplier to see if they have any reason to suspect an adverse effect of washing these materials together. Thank you for your assistance.

HVAC Manufacturer - Westfield, Massachusetts, USA

Q. Our company makes residential electrical boxes. I'm designing a box with a pre galvanized steel plate that need to be grounded with a pig tail with copper ring terminal.The steel plate has an area of 1.75 Sq. In. I'm considering to use a Zn plated steel rivet for the joint and worried if the rivet will corrode. Is rivet corrosion going to be an issue or do I have enough Zn area compared to the copper terminal.

Mathew Thomas- Memphis,Tennessee, US

March 31, 2020

A. Hi Mathew.

Zinc vs. copper is about as bad as galvanic corrosion gets. The electrochemical difference is over a volt, and many school kids are familiar with making batteries by inserting a copper penny and a galvanized nail into a lemon to light up LEDs and power digital clocks.

It is is tough to offer concrete answers about galvanic corrosion because it also depends on the conductivity of the moisture (very low if only rainwater, but much higher is salt or fertilizer lands on the box). And because we can talk about relative areas, but the only area that counts is the conductively wetted area :-(

If the plate is vertical and sheds water so it's usually dry, but conductive glop accumulates under the joint, the area relationship between the same parts may be very different than if the plate is horizontal so it tends to remain wet.

So practical good practices may be better than calculation, and what might prove to be inexpensive, practical, and a big help is to use tin plated terminals and tin plated copper or brass rivets.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I'm looking to create some oil paintings on large, thin sheets of copper and I'm trying to come up with a solution for making the sheets sturdy enough for painting (and to provide attach a wire for hanging). I've thought about glueing some square aluminum tubing to the back of the panel, but is there any chance it will cause corrosion over time?

Casey B.Hobbyist - Phoenix, Arizona

September 24, 2021

Q. I am considering installing aluminum gutter covers on a copper gutter system. There is a narrow area of contact. Is there a tape I can use to effectively separate the two?

Contractor - DALLAS

June 3, 2022

A. Hi Richard. It doesn't require much to block those galvanic currents; black electrician tape would be more than enough. But I don't know what tape adhesive is going to last decades with such exposure. It may not be a big issue since rainwater is not very conductive and the covers won't be very visible. So if the tape is wedged in where it won't fall out and promote blockage, it's probably all you need. But "plater's tape", which is a bit heavier and available in colors, might be good.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. The church steeple is about to be covered with aluminum roofing. The 200 year old weathervane above is made of copper. Is there a way to protect the aluminum from the copper leeching? Removing the weathervane to make a replica has been suggested. Removal would be costly and may be impossible as it is attached to a wooden ball in a finial of three balls attached to the tapered point of the steeple.

Betty Currymember of the Covenanter Church conservation committee - Hortonville, NS, Canada

October 23, 2022

A. Hi Betty. Presumably the aluminum roofing is painted, which will at least minimize the staining from copper runoff. If it is practical for the copper to be lacquered or clearcoated, that would help too.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread