Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Seeking Simple Dip Coating for Brass

2001

I am trying to locate a simple dip coating/treatment for brass that is corrosion resistant to salt water.

Our R&D department once had a clear chemical that when you just dipped a brass part into, it would react with the surface to create a pseudo plating. It would be mostly used for re-machined formally plated parts for repairs and samples, etc. Has anyone heard of such a process?

Thanks

Dennis Bulin- Zephyrhills, Florida, USA

I remember visiting a customer once that used brass to make thousands of the screw bases used in ordinary incandescent light bulbs. He simply put these in a basket, and then alkaline cleaned, rinsed, and dipped in a solution (as I recall) of an alkaline stannous phosphate. This was an electroless process that gave a thin grey coating to the brass parts, inside and out, so that they soldered well, even if on-the-shelf a while. Perhaps, if you can otherwise tolerate the color, etc. your samples could be similarly coated. For the small amount of chemical needed, contact any of several plating supply houses found on the internet, and sponsoring this site, and request a sample.

W. Carl Erickson- Rome, New York

2001

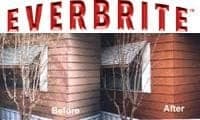

You may want to look at Everbrite Protective Coating. It is a one part clear coating that objects can be dipped in and will provide excellent protection from salt water and salt air. Everbrite can also be sprayed on or simply wiped on larger surfaces.

Teresa SedmakEverbrite Coatings

Rancho Cordova, California

2001

Q, A, or Comment on THIS thread -or- Start a NEW Thread