Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Seeking Iridescent Paint or Powder Coating

Current questions:

Q. Hello all,

Like many people, I'm trying to get that classic iridescent "rainbow" finish on a number of small metal parts (each no more than an inch or two wide). I'm a hobbyist who's trying to do this as simply and cheaply as possible. As far as I can tell, this involves coating the parts with a metal and then anodizing it, which creates an oxide which reflects different wavelengths of light depending on the thickness. It seems like I have two options:

1. Titanium. This seems like the most obvious, and I want the finish to be as close to titanium rainbow as possible, but titanium can't be electroplated, leaving only difficult and expensive processes like PVD. I got a quote from a company that specializes in titanium PVD, and it's more than I'd like to spend on this hobby project.

2. Zinc nickel alloy. While scouring the internet, I've found clues that perhaps a mixture of zinc and nickel can be used to achieve a similar effect. My guess is that this process involves making a simple solution of distilled water, sodium chloride, nickel chloride, and zinc chloride, then inserting a zinc anode and a nickel anode, and attaching the part to the negative terminal of the power supply and dunking it in the water for however long it takes to coat the part. Then, once the part is plated with the zinc nickel alloy, anodize it the way you would titanium.

2a. I think (though I'm not certain) that all of the parts I want to anodize are nickel plated already, so I'm wondering if it would be feasible to skip the electroplating step and simply anodize the nickel coating directly.

If I'm going the DIY route, I'm leaning towards option 2, but I have a number of questions about it. Is it even feasible to get titanium-like rainbow from zinc and nickel? Is my overall idea for the process correct? Are these the right chemicals? Do I need a specific ratio? How much voltage and current would I need to supply? How long would the process take? Are there any other gotchas I haven't thought about? I've never done anything like this before, and I'm not very well-versed in chemistry, so please forgive my numerous questions. Thanks.

- Schenectady, New York

May 26, 2021

A. Hi Kyle. Sorry if I misled you, but I think you misinterpreted what I was trying to say :-(

I doubt that there is likelihood of being able to anodize a zinc or zinc-nickel coating in the way you are probably envisioning. While anodizing titanium can coat it with a partial wavelength thickness of transparent oxide, which can generate the interference pattern for a rainbow effect, I was trying to say that chromate coatings on zinc plating and zinc-nickel plating have some capacity to generate iridescence, as do thin coatings of oil, flame coloring, etc.

There is a video further down on this thread purporting to illustrate a rainbow coating that can be achieved by simple dipping in a proprietary chemical. Anodizing titanium or a titanium coating probably remains the most generic, robust and proven pathway to rainbow coatings.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

June 2021

Rainbow Colored Fish Hooks

Q. I have a friend who is in the fishing lure industry. Recently he received samples of small, rainbow colored treble hooks. These hooks are supposedly carbon steel. He wants to test color some of his new products, but cannot find any information on the process. I have worked with PVD in the past, but that process would seem to be too cumbersome to produce 250,000 small hooks at a time, especially if a rainbow effect is desired. I thought they might be electroplating titanium onto the hooks and then using a current to anodize them. But I read on this forum that titanium cannot be electroplated onto steel. I also wonder if the metal isn't actually stainless and then colored using an electro/chemical process. Does anyone know how this rainbow color is achieved on carbon steel? Or is this a recent breakthrough by our overseas manufacturers. Thanks for your input.

Glenn Dennis- Raleigh North Carolina

September 4, 2021

A. Hi Glenn. We added your inquiry to a thread which discusses rainbow coatings, and as you'll read here, it's not titanium per se which explains them, it is any very thin (partial wavelength) transparent or highly translucent coating where some of the light striking an object bounces off the outermost surface, and some penetrates the clear coating and bounces off the object (or underside of the clear coating). Splitting the light this way, with half or so of it taking the short path (bouncing off the outside of the coating) and the rest taking the longer path (bouncing off the inside of the coating) puts the two portions of the reflected light out of sync with each other, amplifying some wavelengths and suppressing others.

Titanium oxide coatings are probably the best and most robust rainbow finish, but not the only one. They can be done with oxide coatings on stainless steel, burnt oils (heat coloring), oxide coatings on aluminum, and -- it would seem from a video below -- even with proprietary dip coatings.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

September 2021

⇩ Related postings, oldest first ⇩

Q. I am fashioning 1/4 in. steel round stock pieces into the shape of a 20 inch hummingbird. What would you recommend to get an iridescent green or blue finish on the steel? I want the color to look like the actual color(s) of a hummingbird. Thank you.

Jon CooksonCreative Metalworks - Norfolk, Virginia

1998

A. Dear Jon, Without giving you an exact supplier name, I can tell you that if you call a number of powder suppliers you will find that one in particular has a niche for this type of product. Remember that powder suppliers each seem to have their own niche for a property of powder I.E. wrinkle, transluscents, clears, textures, veins, etc.

Bob Utech Benson, Minnesota |

Ed. note: Bob is the author of: "High Performance powder Coating" on eBay or AbeBooks or Amazon [affil links] |

1999

Q. I am looking to furnish my living with karma light iridescent color. Can you please give me some direction on where to search. Thank you

Juana diaz

⇦ Tip: Readers want to learn from Your Situation 🙂

many readers skip abstract questions.

Q. I am looking for an iridescent paint called 280 Chromolair. Web searches returned no info. Does anyone know about this Product?

Jeff Waggoner- Cincinnati, Ohio

2000

Q. I would like to know where I can find iridescent powder for powder coating. We are wanting to experiment with this for one of our products.

Becky Tharp- Oak Ridge, Tennessee

2000

A. There are several manufacturers of the powder you seek, Valspar, PPG One Source, Tiger Drylac to mention a few. Look under the suppliers section of finishing.com for companies that support this web site and you may find additional companies that also can assist you. Good Luck.

Tyrone l. Caley- Jefferson City, Missouri

2000

Q. To whom it may Concern,

I am looking for an iridescent paint to paint on metal. I am not faring too well with a spot to start. I have contacted some of the powder paint suppliers and they don't have what I want. I need to be able to spray this on with an air gun.

Please respond back to me as I would love to try some of this out or find a supplier that would carry this paint.

Thank you

Mert W [last name deleted for privacy by Editor]- Praire du Chien Wisconsin

2001

A. Dear Mert,

One good way to achieve an iridescent look would be to topcoat with a clear lacquer and put lots of thinner in the mix. This will cause the rainbow effect you are looking.

adv.

If you are looking for a metallic coating to achieve this effect, you can take a look at our website, then contact us via email or call us. Hope this helps,

Sincerely,

Jake KochG. J. Nikolas &Co.,Inc.

Bellwood, Illinois

2001

A. There is a type of paint called Chroma-lusion (Dupont), Kameleon and others (PPG, Sherwin Williams). It changes through five different colors and they have about 60 different combinations. cost is about $40/2 oz. Any automotive paint supplier should carry it. Has to be seen in person to get the full effect.

One manufacturer supplies the plates to all the paint makers.

David D [last name deleted for privacy by Editor]- Rochester New York USA

2001

A. Try House of Kolor.

I'm not sure what you mean by iridescent but these people will have it. Good Luck, --Tony

- Spring Green, Wisconsin USA

2002

A. There is a company which specializes in very colorful car paint. It has a line of sprays in all sorts of dichroic colors. A sample kit is around $100. Their name is Alsa Corp.

Anne Y [last name deleted for privacy by Editor]- Bellows Falls, Vermont

April 5, 2008

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I would love to paint the interior walls of my house with an iridescent paint! Not metallic but possibly pastel colors or white with the iridescent look. Can anyone please tell me how to do this? Is it difficult?

Thank you for any help you can offer!

Michelle Martin- Kettering, Ohio

2001

A. By coincidence, I was thumbing through Good Housekeeping today and there was an ad from TruValue Hardware Stores for paint supplies describing how to get some of the weird effects like skyscapes with clouds, flocked finishes, etc.

They showed one that was sort of iridescent, I guess. It involved two layers of paint, close in shade. The slightly paler color was put on first, then the second coat was an enamel in a very slightly darker shade and put on with a rag so that the background color showed through to varying degrees, giving a luminous look. The top coat was actually comprised of one part enamel to two parts of what they called 'glaze' but I don't know exactly what 'glaze' is--perhaps an enamel with no pigment?--but hopefully TruValue will.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2001

A. You have to first paint the wall a flat color of your choice, you can finish over it with a glittering clear acrylic paint, you can find the sample of what you like in a craft store near you (like Michaels) and take it to a hardware store (like Home Depot) to find the match. If you like you can also sponge a darker glaze over it, if you have Home Depot in your area check for accent and texture paints, they have a bunch of brochures and guides for all sorts of beautiful artistic finishes.

Anahita- San Diego, California

2001

⇦ Tip: Readers want to learn from Your Situation 🙂

many readers skip abstract questions.

Q. I want iridescent paint too.

KC Jones- Bedford, Texas and USA

March 1, 2011

Q. I'm working on a project for my chemistry I, and The title for it is "How Does Iridescent Paint Work?" I've looked up on many different websites and was hoping that you would be able to help me out! Thank you so much!

C-C L [last name deleted for privacy by Editor]student - Madison, Wisconsin, Dane County

2007

A. I can't speak for a given manufacturer about how their paint works, C-C, but Jake has told you how it is generally achieved (very thin layer of clear coat lacquer), and I can point you to info about the general principle of iridescence -- which applies to oil sheen on water, the rainbow colors reflected off a CD or DVD, the funny pink-green-purple colors you see in some new automotive headlights, and the many other cases where you see rainbow like reflections.

Iridescence is also seen in carnival glass. Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

2007

July 8, 2008

A. They add pearl dust to paint to get the effect.

Ryan Turcot- Ashcroft, BC, Canada

A. Another manufacturer for special effect paints, especially dichroic effect is Stardust Colors SAS, St. Laurent, France, stardustcolors.co.uk

They propose a few dichroic effects:

- prismatic (create a rainbow reflection), available in particles size from 200µ to 12µm (that is the size of a blood cell)

- chameleon paints (creating color changing effects - from 2 to 5 colors) depending on the angle of view

ARCO IRIS - ST LAURENT, FRANCE

December 4, 2015

Q. Hi,

I know this thread is very old, but I'm desperately searching for a truly clear iridescent coating to restore glass antiques. I'm not looking for the color-changing metallic look like on auto paint that most people today consider iridescent.

Your comment about thinning lacquer caught my attention as most likely to be what I'm after. But could you be so kind as to be more specific? Such as, is it nitrocellulose lacquer? Or acrylic / water based? Some other type?

And is it actually lacquer thinner

⇦ this on

eBay

or

Amazon

[affil links] Warning! flammable!

I should use, or some other solvent like acetone

⇦ this on

eBay

or

Amazon

[affil links] Warning! highly Flammable!

? And what target ratio of lacquer to thinner are we aiming for? 1:3 or 1:5 or 1:10 or what?

Your kind advice will be very much appreciated, thanks!

Brazos Valley Antiques - Waco, Texas USA

January 4, 2019

Rainbow "oil slick" coating on pottery and plaster items

April 14, 2019Q. Hi everyone. I've been reading this thread with much interest. I thought it might hold the answer to a question I've been searching for but alas not.

I have this lovely ornament (I'm thinking it's made from pottery or plaster) of a sardine that I bought in Croatia (I think). The paint effect on it is simply lovely and I would love to try and recreate it on some concrete or plaster surfaces of small items that I make.

I've no idea how to do it though. Is it heat generated perhaps (painting a metallic finish then heating it?) or is it dipped in a petrol on water kind of coating maybe? I simply don't know?!

Does anyone have any thoughts or suggestions for me to try? I would be soooo happy if you could help! X

- Newcastle upon Tyne, UK

A. Hi Wendy. The general "oil slick" look is the result, as we have mentioned, of a very thin translucent coating such that some of the incident light reflects from the outside of the coating and some of it passes through the coating and reflects from the base, and the two portions of the reflected light interfere, canceling out some wavelengths. Where the coating is thicker it's one color, and where it's thinner it's another.

But trying to determine exactly how it was done is not always easy. In the case of titanium it's done by electrically building an anodized layer of varying thickness; in the case of pretty copper items it's done by applying oil and torch drying it to different thicknesses, in the case of carnival glass it's done with a thin metallic salt bath before final firing.

Although I have no actual knowledge of the method used for your piece, if it's pottery/plaster I doubt that either anodizing or torching would be employed. That leaves me thinking it was probably made the way "carnival glass" is made. You can probably google quite a bit about that. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Multiple threads merged: please forgive chronology errors and repetition 🙂

November 11, 2019

Q. I know many people have been asking questions to learn process, techniques and find coatings for creating iridescence on this forum.

I have also seen some experts have suggested lacquer with a lot of thinner creates iridescent coating... I would like put forward results of my experiments.

Lacquer: lacquer thinner

⇦ this on

eBay

or

Amazon

[affil links] Warning! flammable!

1:1 does not cause iridescence

1:2 does not cause iridescence

1:3 does not cause iridescence

1:4 does not cause iridescence

1:6 does not cause iridescence

1:6 does not cause iridescence

Lacquer: Paint Thinner

1:1 causes lacquer to lump up, and is not even soluble...

If anyone has any better suggestions please post them here.

I have pictures of my experiments that I would like to post but don't know how.

- St Thomas, US Virgin Islands

----

Ed. note: Email photos to mooney@finishing.com for posting here.

A. Hello Jerry McDonald!

I don't know whether you ever found an answer for your question about iridizing glass.

Firstly, just in case:

-- Iridescence is caused by the refraction of light through "micro-prisms" (my word) formed by structural unevenness of the surface of a material that cause the light to bounce around in a way that breaks white light into its visible constituent wavelengths.

-- Attempts to reproduce that effect seek to duplicate those "micro-prisms".

-- TRUE iridized glass is made by coating the still-hot glass with metal salts, and then giving the glass a final firing to create the refraction, i.e. the iridizing effect, by disturbing the surface enough for "micro-prisms" to form. The crystalline nature of the micro-structures is critical to the extent and quality of the refraction.

-- To be honest, as a glass artist, it seems to me that "painting" the glass parts of antiques would be analogous to dipping a coin from Ancient Greece in chemical tarnish-remover bought at the local "mega-mart".

If your item uses flat pieces of glass, it'd be best to have them replaced, by an artisan, using actual iridized glass, which comes in 2mm-thick and 3mm-thick sheets; there might be 1-mm sheets?, but I'd have to check on that to be sure. If the objects to be restored have rounded glass parts, look into the possibility of having the glass parts made to order by a Glass Artist who can use Fuming to achieve a true iridized finish.

But, if this is for your own decor, and you'd be satisfied with a painted-on coating:

Look for iridescent medium/paints in good Artist's Supply shops and in Stained-Glass Supply shops, either in your area or on-line, as you prefer. The latter would probably be a better resource.

There are some articles online that describe using a applying "glaze" (thinned clearcoat), letting it become semi-dry, and then using a trowel/large palette knife to apply additional thinned topcoat in a "hatchmark" type of pattern, so that the resulting surface-structure bounces light around is a way similar to those "micro-prisms". I'm highly skeptical and would have to see it to believe it - I think the effect would be more silk-like, rather than "iridescent".

I also did see something about using lacquer. I assume that the "highly thinned lacquer" is supposed to dry with enough surface unevenness to create the iridescent effect, but *IF* it works at all, I think it'd be more by accident than by design. This *might* work with optical acrylic, but actual *natural* lacquer (i.e., the stuff made by the Laq beetle, harvested, and re-suspended in ethanol), well, I've worked with that, and I don't really believe it has much potential for iridescence, even though it *can* be smoothed to give wood a nearly-glass-like finish.

I think it would refer specifically to Nitrocellulose Lacquer, which is the glass-like finish seen on some musical instruments and antique furniture. You could try a very light "sputtering" spray of clear coating to only add a small number of tiny droplets at a time in layer after layer after layer, allowing each layer to dry in between. Note that word "nitrocellulose" - yes, it's flammable and requires care, AND a still and *very clean* environment. And that many layers takes a loooooong time. Agaiin, I remain skeptical and would have to see it to believe it.

I also saw some things on-line called "iridescent topcoat", "iridescent clear-coat", and "iridescent medium". If you're not going to have the glass parts replaced, look up those and similar terms.

- Houston, Texas, USA

September 2020

A. Thanks Kris. Lots of good info in your posting. However, I don't think 'micro prisms' is quite the clearest explanation. Rather when you have a transparent/ clear coating on a reflective object, whether it's an organic coating or a transparent oxide like titanium metal can acquire, a portion of the light landing on it reflects off the outside of the clear coating, and a portion of it travels a bit further and reflects off the surface of the object under the clearcoat. If the coating is very thin (partial wavelength thickness), the two reflected streams of light are out of phase with each other because one traveled further -- and the two halves of the light "interfere" strengthening the greens and cancelling the reds, or strengthening the red and cancelling the greens, etc.

In the case of titanium, many different very consistent colors are obtainable by varying the anodizing voltage, which builds this transparent oxide film to different thicknesses.

(Courtesy of Russamer Lab [a finishing.com supporting advertiser])

But if you do something that results in a randomly varying film thickness (but still partial wavelength) you get rainbows like an oil slick on a mud puddle.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Neo-Chrome Plating

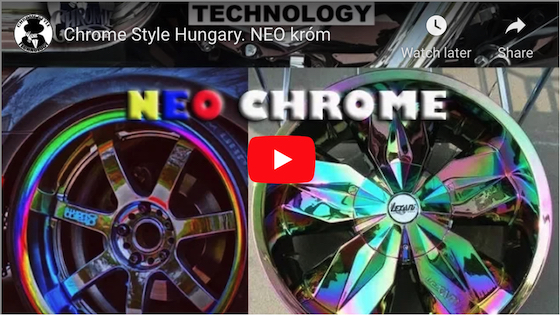

February 4, 2020Q. Hello,

I would like to get advice from the finishing experts about the neo-chrome plating / rainbow plating processes which was easy to find it from automotive parts like wheels, exzos, covers, etc.

We could see the references from youtube as below link.

Can any expert provide some details on this plating processes either the chemical that can be used in plastic and metals.

Aside, where could I get this type of chemical.

Thank you and hope the experts could share some information.

Warmest Regards,

Jay ChuahHobbyist - Malaysia

A. Hi Jay. I can't speak for the manufacturer, but I think that "Neo-chrome" is their trade name for their chrome-look paint, rather than their iridescent process. Chrome look paint is available from a half dozen different suppliers, and involves a base coat of paint, followed by the reflective layer which may be either two-component silvering (silver nitrate plus an oxidizing agent) as is used in making mirrors, or tiny aluminum flakes, followed by a final clear coat. But optimizing the formulations of these three layers is the result of a lot of research & development.

The iridescent coating is some sort of clear coat, but rainbow coatings are also available from many vendors offering different technologies. I don't know whether this clearcoat is organic, or silicate, or zirconium or what. But the principal is that very thin clear coatings of varying thickness will cause a rainbow effect as light bouncing off the top of the clear coating interferes with the light reflected off the substrate. We cannot post actual formulations of this clearcoat anyway, except references to published information, as we can't know he legitimacy of a poster's knowledge and must be careful to avoid crowdsourcing industrial espionage.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

February 2020

February 15, 2020

A. Hello Jay Chuah!

I did some rummaging around on the 'net. For automotive applications, I did find "car wrap" called "iridescent chrome film" that comes in several colors - $400 USD for a 5' x 60' roll. It looks like the laser-etched wrapping paper and similar refractive items, so I assume it's a laser-etched plastic film.

Otherwise, I'm commenting from an "artsy" person's perspective, not a technical one, so I don't know whether the following will help; but at the very least, there might be some ideas for searches, so here goes:

The three methods I know of for creating iridescence are [1] vacuum vapor deposition of a very thin layer of heated metal, [2] use of some form of interference pigment, and [3] finely-etching a material's surface.

None is a plating technique, as I understand the term.

(At the very end, I add a fourth method, because I just found out about it a little while ago!)

The proverbial rub with interference pigment is that it usually only involves two, or at most three, color-shifts. For example, green to violet, or blue to red. Not the full 'rainbow'. But its advantages are that it's available, it's fairly cheap, and especially, it's easy to use since it only needs to be mixed into a clear medium - it's even used in nail polish! You can buy interference pigments online.

Some potentially-useful information links for vapor deposition:

https://www.youtube.com/watch?v=-59VAnvAGLI (a 'video', more like animated flashcards, showing the basics of the vapor deposition process)

https://www.cloudynights.com/topic/615319-vapor-deposition-chamber-anyone-want-to-try-doing-a-diy-on-one/

Re: etching, you might enjoy some of these:

https://gizmodo.com/scientists-create-beautiful-iridescent-material-that-co-1825115747

From what I could find, the iridescence of truly-antique glass is due to physical etching by fine particles. I looked around for info on how to do this on purpose, but had no success - at least, not yet. I did see one example of acid-etching ceramic glaze to get a somewhat-iridescent effect. And, of course, laser-etching was mentioned at the beginning.

[4] controlled chemical oxidation to create an iridescent patina on metal - this appears to be via oxidation, rather than via chemical etching:

https://www.ganoksin.com/article/iridescent-patina-recipe/

I have no idea whether this would work on chrome, though.

Best of luck with finding what you need :)

- Houston, Texas USA

![]() Nice exposition, Kris!

Nice exposition, Kris!

Here I thought it was always a clear coating (whether organic or a transparent metal oxide), but that's actually only one of several ways iridescence can be achieved. Thanks!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

March 2020

----

Ed. note: This thread focuses mainly on using lacquers, paints, powder coatings, dips in metallic salts, etc. to create iridescent/rainbow/"oil slick" coatings.

It is also possible to anodize titanium or titanium coatings to build such coatings from titanium oxide; thread 33644 focuses on that.

September 27, 2020

Q. One of my customer wants to setup a plant for Rainbow coating of his Buckles for bags and belts. The raw material is SS 304 and 202 grades and also Brass.

I am not aware of this process but I have seen some pictures in Google.

Am more interested to know and setup plants for that.

Kindly help.

DHANASEKAR DACKSHINAMOORTHY- Chennai India

A. Apologies for the 6-month-late response sir, this type of iridescent coating is achieved by physical vapor deposition (PVD) of a thin film of titanium oxide or other materials onto the metal substrate. As to the setup costs or equipment, I recommend looking online for PVD setups and so on.

Will Chambers- Calgary, AB

April 5, 2021

A. Although PVD applied titanium coatings can create this look, and are probably the most robust and wear-resistant approach, the general look can be achieved with dip coatings as we see on this page. Further, iridescent yellow chromates can produce at least a bit of this look on zinc plating, with even more purples and reds evident on zinc-nickel alloy plating. I'd bet that if a chromate conversion coating supplier put their mind to it, and a decorative applicator worked on it on individual pieces rather than bulk processing, that a very close imitation on zinc-nickel plating would be possible :-)

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

April 2021

⇦ Tip: Readers want to learn from Your Situation 🙂

many readers skip abstract questions.

Q. Is it possible to get the rainbow oil slick look on acrylic plastic tumblers?

Shustine mock- Portland Oregon

November 10, 2020

A. Hi Shustine. It's readily available on the clear eye shields of motorcycle helmets, so I'd have to say yes.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

October 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread