Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Voltage spikes and amperage drops

Q. Issues with my nickel bath, recently my voltage went from normal 5 volts to 15 volts during plating I added about 25 percent more water to level it out and everything went back to normal. Could too much Nickel in the bath cause this?

K.G. Kenbo- Texas City Texas

January 31, 2024

A. Hi K.G.,

Sorry, it's not clear to me what you are describing. What is it that determines voltage in your setup? Normally, you adjust the voltage on the rectifier as required or desired, such that if you set it at 5V, it's 5V; and if you set it at 15V, it's 15V. Are you trying to plate at constant current and letting your rectifier choose the voltage necessary to do so? If so, what current density are you trying to plate at?

Also, I don't understand how you can add 25% more water ... the bath had evaporated to only 75% of its original volume? That sounds quite extreme. Is this a production plating operation (barrel or rack?) or are you a hobbyist who hasn't used the bath for a very long time?

You aren't by any chance trying to plate on aluminum? Thanks.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I'm plating aluminum, the part I was plating should have plated with 5 volts and 25 amps. It plated for a few minutes before the voltage jumped to 15 volts . I added water to the bath and the voltage went back down to 5 volts. Is my bath saturated with nickel or is it the rectifier possibly going bad?

Kenbo K G. [returning]- Texas City Texas

February 1, 2024

A. Hi,

Voltage going crazy like that certainly indicates a defective rectifier or defective contact (if contact goes bad and you are plating by constant current or constant current density (why?), then voltage will rise in effort to deliver the chosen amperage).

No point in a baseless wild guess whether nickel is too concentrated without any data on its concentration. Tell us about your zincate process please.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. High voltage amps going down:

1. Check rectifier-may be rectifier problem2.

2. Nickel anode bag plug up-replace bags

3. Check nickel concentration and pH

Popatbhai B. Patel

electroplating consultant - Roseville, Michigan

Q. There is an issue in my copper-tin bath: Voltage spikes and amperage drops during the plating process; the thickness is low and Cu-Sn ratio concentration on deposits should be 50:50 but the copper concentration is decreased to 10-15 and tin concentration is increased to 90.

The bath has 4 components (potassium hydroxide, potassium cyanide, copper cyanide, and potassium stannate). Could you please advise me on the bath?

- Houston, Texas

February 22, 2024

A. Hi Ava,

I think there is little chance that your solution composition has much to do with this problem.

Almost surely you have a rectifier problem. Have you had a rectifier serviceperson attempt to troubleshoot this?

Are you rack or barrel plating? Does this happen with every load?

what happens when you plate Hull Cell panels with this bath? Thanks.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Actually I'm sure about the rectifier. It's barrel plating, and it is happening for all loads. I suspect there might be an issue with anode. Is it possible that our anode has become passivated ?

Ava Bahrami [returning]- Houston, Texas

February 23, 2024

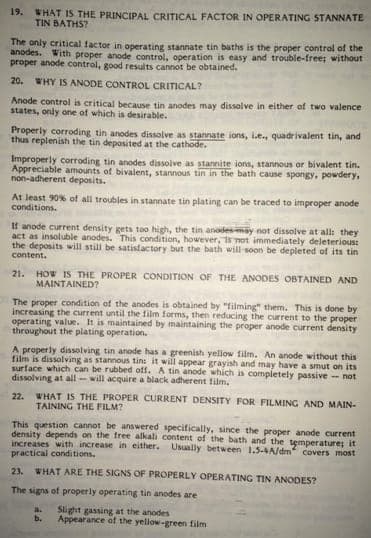

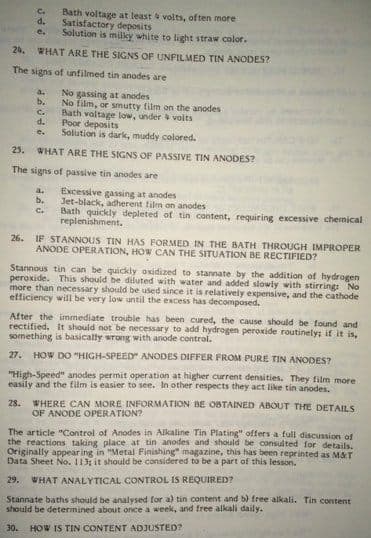

A. Hi. Perhaps I misunderstood the situation you are describing. Tell us about your anodes please. Tin anodes do require "filming" per Garden State Branch AESF "Basic Practical Electroplating, 1986":

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi Ted,

my problem is in regard to copper concentration on deposit it is very low about 5% on the contrary. Tin concentration is high -- it reached to 94% and thickness must be 8 micrometer but it is 3.

- Houston, Texas

February 26, 2024

A. Hi Ava. Apologies for continuously misunderstanding you :-)

Copper anode polarization does occur in copper sulphate plating if the copper anode dissolves too readily, producing a too-rich solution near the anode. But I am not personally familiar with it occurring in cyanide copper or cyanide copper alloy baths -- but my experience is limited.

Let's see if this becomes my 3rd strike: I would expect the problem to be more closely related to cyanide concentration or temperature than anode passivation.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread