Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

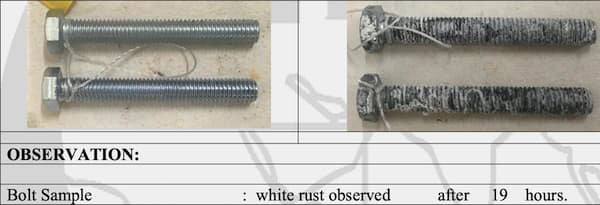

White Rust on Zinc Plated Bolts after 19 hrs neutral salt spray

Q. Dear Community,

I am having issue of Zn Plated bolts getting rusted in 2-3 months time (in real life, indoor environment with no corrosive fumes etc). These are the bolts which are packed in plastic bags and kept inside boxes for despatch.

So I decided to check the SST & Zn thickness. Zn plating Micron is 12.90 - 11.89 (say avg 12 mic). The SST is 19hrs. (see attached SST report).

The Plating factory says they did Electro Zn plating + Trivalent Blue Passivation. There is no top coat or lacquer.

I have gone through the other posts on this forum, which says that SST is not the real measure, however appearance of White rust in 2-3 months in real life condition (indoors and no fumes of any corrosive media) is also not acceptable.

Can anyone please help what is that I am missing, where can I tell the plating supplier to improve. Will Water Soluble Lacquer help increase the SST of white rust. and if yes, by how much ( 1.5 times or 2 times).

Thank you in advance

- Mumbai Maharashtra

April 15, 2023

A. Hi Jagesh,

Although hours to failure in salt spray testing can be a poor way to judge the quality or real-world corrosion resistance of a finish, failure in 16 hours is completely unsatisfactory -- especially considering that the thickness of the zinc plating is well beyond the more common practices of 5 or 8 microns.

Most trivalent chromates require a "top coat" or "sealer coat" ... usually a proprietary product of the same supply company which offers the trivalent coating process. I do not understand this idea of no top coat unless this plating shop is using the rather unusual 'thick film trivalent chromate'.

Yes, a water soluble lacquer would help somewhat but I don't think it's the right answer. The right answer is that this chromate without a sealer coat is unsatisfactory.

(One note, of course, is that you have to do the SST immediately upon receiving the parts -- you can't wait until they're already failing. If the parts were poorly dried, then sealed in plastic at 100% humidity for 2-3 months, I suppose they could fail a SST test within 16 hours.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. White rust is an indication that something is wrong with the passivation. Red rust indicates that the zinc layer is too thin' which is not true in your case.

Trivalent passivation requires a sealer.

That will solve your problem.

Sara Michaeli

Tel-Aviv-Yafo, Israel

![]() Thank you Ted and Thank you Sara for answering the problem.

Thank you Ted and Thank you Sara for answering the problem.

Yes Ted, the Neutral SST is done within a few hours of plating.

I will ask the plating service provider to do the Sealer process after trivalent passivation.

I hope it will solve the problem.

I am also planning to purchase the SST testing equipment in my factory so that we can do the test quickly and know the deviations.

Will update the post about new SST results post sealing process.

Thank you again. Ted and Sara

- Mumbai, India

April 21, 2023

A. A tri-pass needs a post treatment.

Sara Michaeli

Tel-Aviv-Yafo, Israel

June 21, 2023

A. Trivalent passivates come in a number of variants. Thin film trivalent passivates are (IMHO) often not much more than a bright dip with a little trivalent chromium added. "Thick film" passivates (e.g., Sur-Tec's based on the Preikschat patents) are much thicker (up to 900 nm) and give better salt spray protection than conventional hexavalent conversion coatings. There are also "no-rinse" trivalent passivates that offer even more corrosion protection. Some of the thin film trivalent passivates have such a small amount of trivalent chromium that a sealer doesn't help much. (In case you were wondering, I can be very opinionated on this subject. But I've done a lot of research to back up my opinions.)

Tom Rochester

CTO - Jackson, Michigan, USA

Plating Systems & Technologies, Inc.

June 23, 2023

Q, A, or Comment on THIS thread -or- Start a NEW Thread