Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Source of Contamination on Hard Gold Contacts?

Q. My name is Sharath, Quality Engineer.

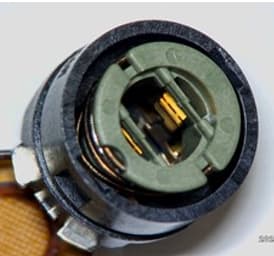

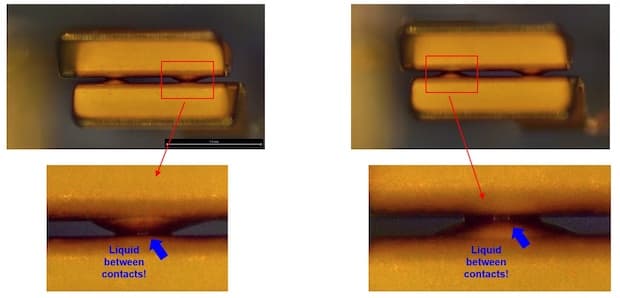

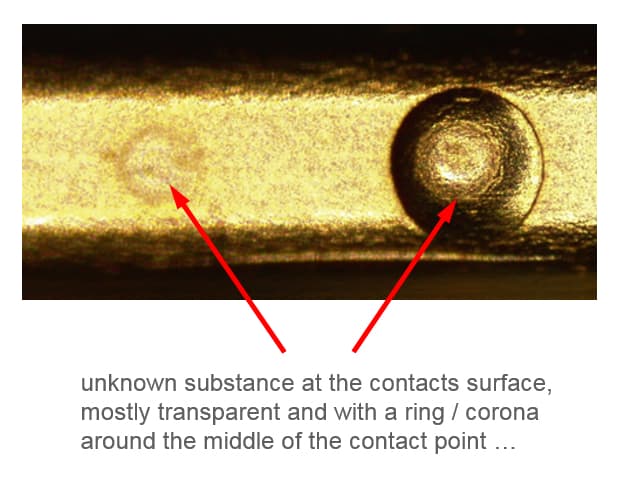

Problem description : We receive switches in a reel from our supplier as a raw material for producing our end product. The switch inside consists two closed contacts which are coated with Hard gold flash layer. These switches are assembled in the SMT Process on the PCB. Our product currently have a failure rate of 2% which are all electrical failures, caused by the switches. The defects parts were sent to the supplier for analysis, after analysis the supplier admitted that there is a white pollution between the contacts which is the main root cause for the electrical failures. We have opened the switch before the assembly process and observed liquid between the contacts, exactly where the pollution is traced. We approached the supplier again showing the images. They have said that the liquid is the grease which is normal in the switch. (Applied to the spring in the switch). They have analysed the Grease and White pollution at the external laboratory and observed that they both are not same. Now our supplier says that this pollution is caused from our process. We have not changed anything in our process and suddenly we have 0.5-3% failure rate from each production. (The failure rate is not constant from each production rather it is always fluctuating. The question is, Is this really a pollution or a hard gold flash layer defect. I attach the images for the better understanding of the issue.

Thank you and if I've missed any information please let me know. Regards Sharath

Sai Sharath Akula- Dresden, Sachsen, Germany

June 3, 2022

1. What is under the "flash" of gold?

2. How thick is a "flash"?

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

A. Hello Sai,

Mr. Probert has some good questions and after reading your post I am a bit confused. Are you saying there is grease applied to the springs before Solder Mount? If the electrical failures are 2% and under and are sporadic, you may want to put the plating process under engineering control. There is a possibility that it's inadequate rinsing between and after the plating processes where solution entrapment is occurring. It would also seem to me that a switch would have a thicker deposit than just a gold flash. A gold flash is usually only 3-5 microinches.

Retired - Cazenovia, NY USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread