Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

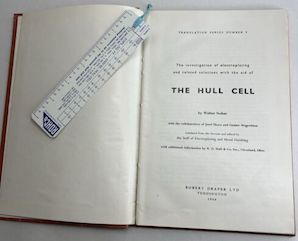

Defects on test panel left in the water

Q. we are a galvanic company, with a coal column water purification plant. Every month we have white spots on the nickel-plated Hull cell panels, then on the pieces.

Weekly check conductivity, pH, surfactants, cyanide, chromium, phosphorus, ammonium, chlorides, sulphates, cod. When we got the spots, the COD took on a very light green color (USING THE HACH KIT) which is unusual. CAN SOMEONE HELP ME?

Lavinia Miconi- Belluno Italy

May 17, 2022

A. Hi. You say you are using activated carbon to treat your water, and that this problem occurs monthly, and that you are detecting higher COD when the problem occurs. I think a reasonable guess is that your plant is not changing the activated carbon soon enough. I think you must change the carbon sooner.

If I am understanding correctly, you are putting clean test panels on a plating rack and plating them in your processing line, but not actually doing Hull Cell testing. It would be interesting to know whether this fogging occurs across the whole current density range by actually plating a test panel in a Hull Cell. Good luck.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

May 2022

Hi,

Thank you for the answer. =) I try to explain better this concept.

We have an ion exchange system to treat the rinse water, made up of activated carbon, cationic and anionic ion exchange resins. When we have this problem we regenerate the columns with soda and hydrochloric acid and wash the carbon. The problem doesn't shows for about one month. By analyzing the parameters, I notice an abnormal coloration in the COD but the other parameters don't change. The COD should turn dark brown at high cod values but instead turns light green, as if something (which I assume is responsible for the problem) reduces all the potassium dichromate contained in the COD vial.

I put this nickel-plated panel in the rinse basin and found it like this in the morning.

We understood that the solution of this problem is regenerate the columns but I try to understand what is the origin for this problems. Why we found this ? =)

- Belluno italy

May 18, 2022

A. 1). If you treat your rinse water for reuse in your production purpose, you monitor the conductivity of the treated water should be sufficient. You may need to tighten the conductivity range if your current setting not satisfied.

2). If you treat the rinse water for the requirement from your local environment protection authority, as your COD high, your anion exchange resin (R-NH inside the column probably need change (because you regenerate it at not good performance).

- Singapore

June 1, 2022

Q, A, or Comment on THIS thread -or- Start a NEW Thread