Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

Thread 613/39

Electroless nickel plating testing with UAN solution (Urea and Ammonium Nitrate in water)

October 4, 2021

Q. We are using electroless nickel plating (high phosphorous) process to get corrosion resistance.

As per ASTM B733, customer need service condition 2 (SC2) [13 micrometers thickness].

But our thickness is around 20 micrometers.

Base metal is 4140 (heat treated) and casted finish.

Customer use this part in fertilizer environment.

So as per customer request, we are spraying UAN 28 (solution of urea [30 g] and ammonium nitrate [40 g] in water [30 g]) to plated part in every 8 hours for 48 hours to test the corrosion resistance.

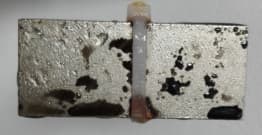

We have done many tests and recently we found that during this test there is some black color spots appear on the surface.

What could be the reason for this?

Denuwan Devendra- Western province, Sri lanka

publicly reply to Denuwan Devendra

A. Hi Denuwan,

The best recommendation is to contact your electroless Nickel chemistry supplier. They may have information about such defects.

I cannot comment about Urea/Ammonium Nitrate corrosion test, but I have seen some similar black marks on electroless Nickel after extended water or salt spray exposure. It may be a surface tarnish: some micro-amounts of Ni Oxides and Ni Sulfides (if Sulfur is included in process additives).

To ensure that Nickel is not compromised and there is no base metal corrosion through Ni crack, probably you can try to cut (cross-section) the black dot and observe the Ni cross-section under a microscope. Also, probably you can try Ferroxyl test (mix of Ferricyanide with Chloride) - see ASTM B733. It is a test for coating porosity on iron based substrate. If iron/iron ions are accessible from coating surface, blue spots should appear.

Good luck.

- Winnipeg, Canada

October 14, 2021

publicly reply to Leon Gusak

Q, A, or Comment on THIS thread -or- Start a NEW Thread