Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Aluminum corrodes after stripping the anodizing

Q. We have a batch of 7075 aluminum parts that were stripped of the anodizing due to a process not being done by the anodizer. When we received the parts back we tumbled and rinsed the parts with water. We shipped them back to the anodizer. 3 weeks later the anodizer opens up the boxes and says the parts are all corroded and they can't do anything with them.

Can anyone tell me what is happening or happened to these parts?

RYAN KRAAI- Sioux Center, Iowa

September 16, 2021

|

|

A. Ryan - Green Mountain Falls, Colorado September 29, 2021 September 29, 2021 A. Ryan supervisor - Cicero, Illinois Saporito Finishing Co.  |

Q. Dear All,

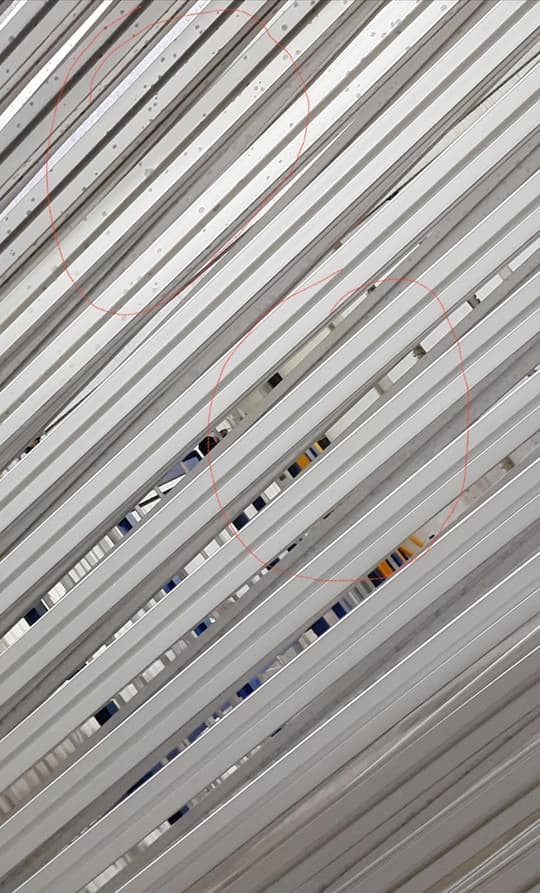

Some bars (mostly stripped) are being corroded nowadays but I don't find source of problem. As you see, some bars include both corroded and non-corroded profiles in same bar (type II anodizing of 6063 alloy).

How can we explain these defects? Is it only related to metallurgical effect of profiles, or should I seek the cause in the anodizing line?

Alaattin Tuna- TURKEY Sakarya

October 9, 2021

October 16, 2021

A. Alaattin

A good first rule of thumb is whenever you have visual defects in a finished part, look around to see if you have any more parts around that have not been processed. This may give a clue to what is happening. Check if there is any similarity between the finished product and unprocessed parts. I would not look into anodize process yet but rather the material. The photos are not the best, meaning a close up of the defect. It is possible there was pitting on the original parts but someone may have performed a light polishing operation skimming the surface trying to blend the pits. An etch process may have broken through the polishing now exposing what was wanting to be hidden. We know that anodizing enhances various types of metal imperfections.

supervisor - Cicero, Illinois

Saporito Finishing Co.

Q, A, or Comment on THIS thread -or- Start a NEW Thread