Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

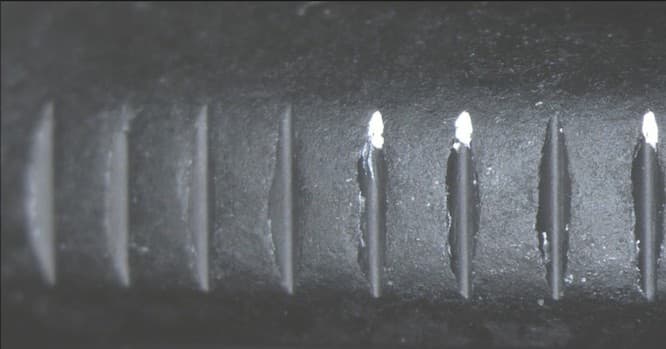

White powder on anodized finish

August 12, 2021

Q. I am a machinist and we CNC machine parts. We received a batch of straight knurled knobs back from type 2 anodizing. In a few random places there is a white powder substance on top of the anodizing. The anodizing is perfect under the powder. The powder cleans off with a toothbrush.

We run these same knobs with the same process all of the time without issue.

My anodizer says it is our fault because a burr on the knurl entrapped the seal coat. I contend that if a burr was the problem then there would have been other imperfections in the anodizing due to entrapment of other chemicals in the processes. It is simply a matter of the seal coat not being rinsed off properly.

What do you think?

- Pomona, California

A. `I am no machinist, but I don't think knurling is a very clean process. It results in folded edges and smeared material. These little void areas will wick in process solutions which are nearly impossible to rinse off. I would bet that you are seeing sulfuric acid electrolyte solution which is drying out and blooming sodium sulphate crystals

Chris Jurey, Past-President IHAALuke Engineering & Mfg. Co. Inc.

Wadsworth, Ohio

September 2, 2021

September 7, 2021

![]() Hi Chris,

Hi Chris,

Yes, knurling is formed by rolling dies on a spinning part so it is difficult to control the surface finish. We have been making this same part with the same process for 10 years and this is the first time we have had a problem. We have even used the exact same dies on another batch since the above parts and did not have a problem.

- Pomona, California

Q, A, or Comment on THIS thread -or- Start a NEW Thread