Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Pitting in Aluminum Threads after Alodine

March 17, 2021

Q. I am in incoming inspection for an aerospace supplier.

We have a "Pitting" issue in threads, two separate parts from two separate platers.

Material for both parts: 7050-T7451 thicknesses is 6-inch plate and 3.5" plate.

During the machining process, we use TRIM MicroSol 690XT parts that are washed and dry before shipping.

Etch for Penetrant Inspection, holes are masked prior to etching, Chemical conversion Coating using Alodine 1200 or equivalent.

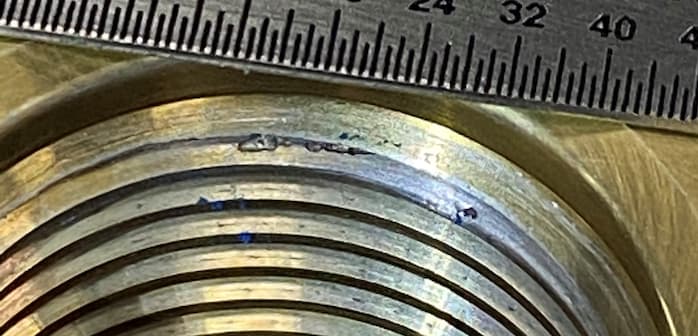

From the attached photos, you can clearly see the "pitting" in the threads. This is typical of what we are seeing on the last several shipments.

Any suggestions?

- Decatur, Alabama

A. This may be a "stretch", but let's consider that the heat from heat treating and/or dull machine threading, has brought the 5% zinc out which then fell out and left pits. "Been there done that".

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

March 19, 2021

A. You say the holes get masked, but the pattern seems to suggest that there might be ingress of something (etching solution perhaps?) into the threaded hole and then it may be sitting there un-rinsed doing the damage.

Ask how the holes are masked and part orientation on the rack to see if the damage is occurring on the bottom of the holes -- suggesting the etchant pooling there.

- Riga, Latvia

March 27, 2021

![]() Thank you for your comments.

Thank you for your comments.

- Huntsville, Alabama

April 5, 2021

A. Kevin

The part in the upper photo looks to have galling as opposed to pitting. But it does show signs for retailing / touch-up.

The part in the second photo appears to include another process in addition to pre-penetrant etch and conversion coating. It almost looks like anodize on the surface surrounding the hole.

The slots for the locking insert make it challenging to get a good seal to keep solution out, as evidenced by the leakage / coating on the chamfer.

The pitting is likely not from the etch process, but possible etch remaining in the threaded hole (wasn't unmasked & rinsed properly). If the additional process was anodize, the same inadequate masking could cause the same. The same path that allows the acid to enter will also allow some current to enter. That creates a rather hostile environment for aluminum.

- Green Mountain Falls, Colorado

April 15, 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread