Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

White lines at masking edges when stripping zinc galvanized steel

March 2, 2021

Q. I am creating two dimensional artwork on galvanized steel panels. To create the design I put vinyl on some areas, leave other areas exposed, and strip the zinc off of the exposed areas by dipping the panel in muriatic acid. (The concentration: I use product sold for swimming pool maintenance. Time: 30 minutes.) Over some days the exposed areas then rust and the covered areas remain shiny, creating the design. I then remove the vinyl and seal using Deft Wood Finish.

My main question relates to a white residue, a white line, that forms between the rusted areas and the zinc areas.

My project differs somewhat from the projects addressed in several threads on this site in that I want the patina only in the areas stripped of zinc, not in the areas covered with the vinyl. It is in the border between the two where the white residue appears. I do not want to mar either the rust or zinc area.

From thread 0009 I understand that: 'White rust is zinc hydroxide that has been inhibited form evolving to zinc carbonate due to the lack of free flowing air on the galvanized surface'

If I catch the white early enough I can scrape it off with my fingernail. (Tough to do on such large surfaces and imperfect outcome.) A little further along and the white is more difficult to remove, and scraping mars the patina at the border between the rust and the zinc.

How can I either prevent the white residue, or remove it, without affecting the rust patina?

My second question relates to creating the rust patina. This question is addressed in https://www.metalgeek.com/archives/2006/06/13/000065.php but I pose it again because my project differs from the ones on that thread (I want both zinc and rust areas preserved) and in case anyone has additional thoughts on creating a rust patina on galvanized (hopefully without the white residue).

I've experimented with: no treatment, hydrogen peroxide, salt, vinegar , repeated misting with water (each of those individually and in combination), and gun blueing. Each has its own drawbacks (I'll not detail here given how long this post already is.)

Thanks for help anyone can offer.

Particularly with the white problem.

vitawells.net - Berkeley California

A. Hi Vita. That's beautiful work and I appreciate that you want crisp demarcation. I don't have an exact answer for you, but I suggest that rather than focusing on how to remove those white lines along the masking edges, you put all your effort into preventing them from occurring. I would suggest experimenting with small test coupons, trying a different masking material and different stripping acid, perhaps sulfuric and citric.

Obviously, something is happening right at the edge due to undercutting, residue, or some surface phenomena which slows the zinc removal at the edges; and I would think that either the maskant or the etchant can be improved. When printed circuit boards are made, with numerous very closely spaced lines, the copper must be etched away exactly, to far greater resolution than you require, with no edge phenomenon of this sort. So I certainly think it's possible.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

March 2021

A. Vita

If you have not done so already, I would add solution agitation to your stripping process. Maybe use an acid resistant brush to facilitate stripping at the interface.

- Green Mountain Falls, Colorado

March 3, 2021

March 4, 2021

Thank you Ted and Willie for thinking about this.

Willie: I think you mean that I should agitate the solution during stripping. I'm doing that. If that's not what you meant would you please let me know?

Ted, I agree that I must figure out how to keep it from forming in the first place.

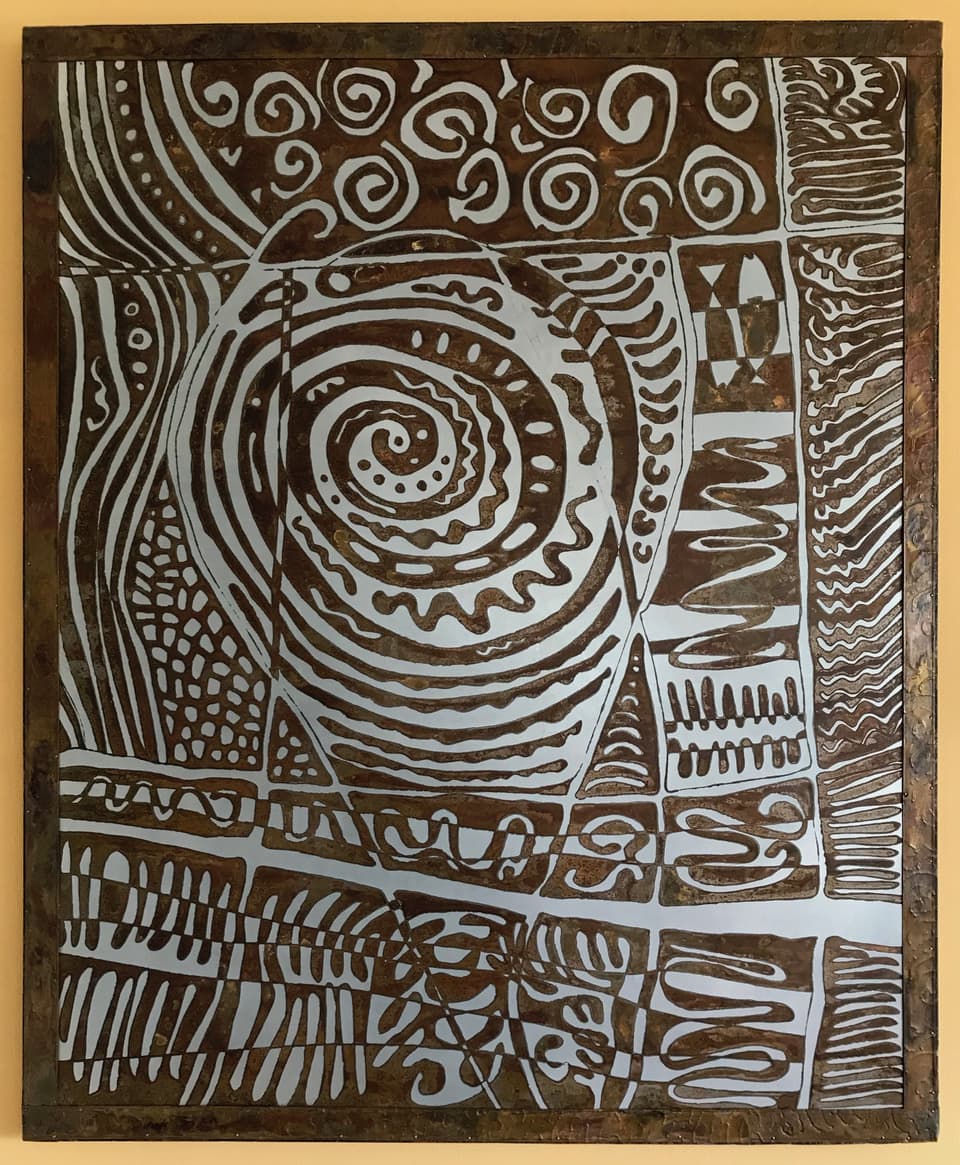

I'm using muriatic because I'm replicating some work my late aunt did. I know she used galvanized steel and muriatic acid but little else. Nothing on concentration, time, resist, or other treatments. Image attached:

Here's some of my additional research:

"What is White Rust?

White rust is a white powdery deposit formed from a natural corrosion process that can occur on any new zinc coated steel product. ... Zinc is a very durable coating for the purposes of providing sacrificial protection to the underlying steel substrate but, because it is reactive to water, great care must be taken in storing it correctly. That is why it is often referred to as "wet storage stain".

The white powder is actually zinc hydroxide -- the substance formed when zinc reacts with water and air - and it gradually consumes the zinc coating; this process is most likely to happen in wet conditions with inadequate air circulation."

Second resource:

"White Rust Formation

Pure water (H2O) does not contain any dissolved salts or minerals, and will react swiftly with zinc to form zinc hydroxide -- a bulky white and moderately unstable oxide of zinc. When newly galvanized steel is exposed to pure water (for example, rain, dew, or condensation) in an oxygen-deficient setting, the water will continue to react with zinc and slowly corrode the coating."

I've done 24 tests over the last four months, early ones with a lot of moisture, later ones keeping the test object as dry as possible. I don't see how I can keep the border perfectly dry since it has to go into the acid bath. Nor do I see how I can get the steel to react with oxygen (rust) but the zinc at the border not to.

For the resist I've tried contact paper, heat transfer vinyl of different thicknesses, and cold adhesive vinyl. Cold adhesive works best. I've not found other resist materials that make sense for the application. I welcome ideas.

I also tried gun blueing. It rusts pretty well but doesn't address the zinc oxide.

I've varied the time in muriatic from 10 minutes to four hours. 15 minutes is plenty and more compromises the integrity of the line.

I've solved a lot of issues. The zinc oxide is the outstanding problem.

I welcome any suggestions and thank you for your thoughts.

Vita

vitawells.net - Berkeley, California

March 2021

A. Hi again. Glad to see that you are not content to let your aunt's legacy die with her -- it's certainly stunning work.

I have to ask though if you are 100% sure that this is rust with a Deft Wood Finish seal? Because, not being an artist, I've never seen rust that dark brown. It always looks redder or orange-er to me; and in fact your own piece seems to have an orange cast that your aunt's doesn't. I'm looking at a picture rather than the original art, of course, but from here it looks like some sort of paint.

Going only by what I see, I would wonder if she did not use highly diluted HCl to make paint adhesion possible, then scrub the whole sheet with a solution of fine pumice / Bon Ami ⇦ this on eBay or Amazon [affil links] for a matte look, then paint it. It looks like there is a border of beige paint, and inside of that a brown-over-beige inner frame. Then again, maybe I'm just seeing what I'm talking myself into :-)

Back to the white zinc oxide though, I think this is undercutting under the edge of the masking. Maybe a wooden roller used for wallpaper seams would improve it.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Vita

Before we address agitation...

Presuming you are using a Vinyl tape to mask, it is typically pliable and subject to lifting when you cut it. The white lines conceivably could be from the acid getting under the mask at the cut edge and partially dissolving the zinc to be protected. 2-mil polyester tape might be a better choice for the masking material. It is likely better at providing crisp demarcation lines. Consider looking at the edge under magnification while the tape is still in place after stripping.

If the problem is not tape lifting, it might be due to lack of agitation. My experience has been that the interface is the last to strip due the step / inside corner that is created by the tape/mask. Stripping solution is not readily refreshed due to this. Providing solution agitation will help. I would look to use agitation that reasonably could be called vigorous.

If the artwork is laying flat in a pan, vigorous agitation is not really practical. Best if you have a container deep enough to orient the part vertically, and room to move the panel back and forth at least a distance equal to the length of the part. If this is not practical, use the AR brush to scrub the submerged surface to create the agitation. The brushing action would be constant for the duration of the strip.

Play with a test piece to experiment.

- Green Mountain Falls, Colorado

March 5, 2021

![]() Thank you Ted and Willie for your comments and suggestions.

Thank you Ted and Willie for your comments and suggestions.

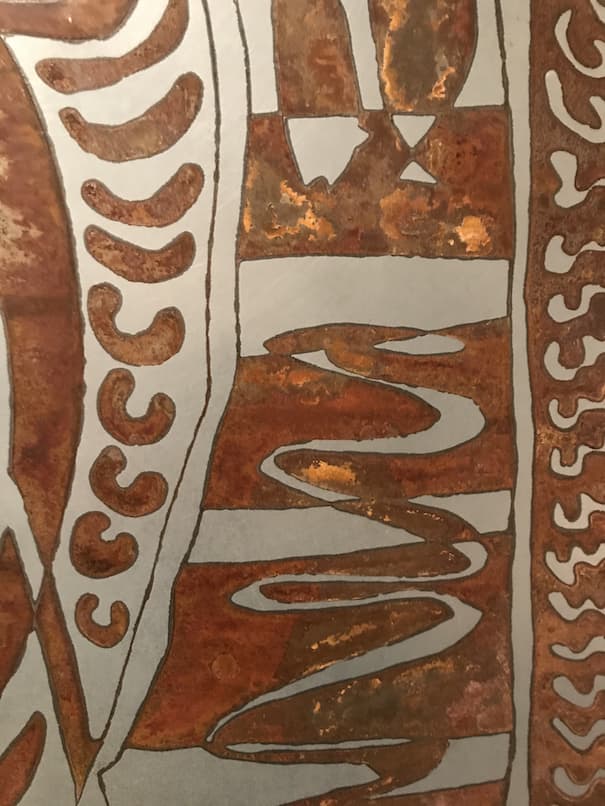

I am 100% sure the process is muriatic acid on galvanized steel. It is the details of execution that's giving me fits. Please see the attached image for a detail of my aunt's work. You'll see the rust - a wonderful, visually complex result.

I am interested, Willie, and your suggestion about polyester tape. Tape will not work since the pieces are 15' x 3' and seams allow for seepage. I have a piece I salvaged from her studio that was in progress. The masking appears to be something other than vinyl but I have not been able to figure out what it is. I've shown it to people in a range of disciplines, including plastics - no luck. I went with vinyl as it was the closest I could find.

Perhaps the person I spoke with in plastics was not knowledgeable enough - an employee at tap plastics (https://www.tapplastics.com/), but retail. At the store.

At your suggestion I've looked for polyester sheets on the web but have not found anything yet. I welcome thoughts on where I might be able to procure a polyester sheet as you describe.

I think I want adhesive on one side but it's not clear to me that there's adhesive on the sample I salvaged from my aunt's studio. They are too large for heat transfer in an oven, though I could use a hair dryer or iron.

There are no bubbles on my aunts sample so I had assumed it wasn't applied with heat. With vinyl, eliminating bubbles requires slow incremental application, pushing bubbles out as you progress from one side to the other.

They are also too large for vertical agitation. I'll see what I can do flat. Test number 25 (a) will be the project today.

I appreciate your reflecting on this.

vitawells.net - Berkeley California

A. Hi again. Art flabbergasts me since I haven't any talent; and the shapes you are masking comprise an unthinkable lot of work ... but masking per se shouldn't be this hard, it's done all the time and to greater precision without any undercutting even under taped seams. So let me ask this, which is within my range: Is the galvanized sheet spotlessly clean before you mask it? Do you apply the masking wearing plastic gloves to be sure there are no finger oils on the sheet? Anything short of spotless can allow undercutting.

Your aunt's galvanizing looks perfectly matte, very different than store-bought, more like scrubbed with pumice (which is an excellent way to achieve perfect cleanliness, too).

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

March 2021

![]() Hello Ted,

Hello Ted,

My galvanized is perfectly clean. My supplier delivers it with PVC coating, A protection during transport. I clean any grunge with 409 or equivalent and follow with several rounds of alcohol until a pristine white rag returns pristine white.

I use new gloves with every piece so they have no residual oil or grease. I am meticulous in applying the vinyl, leaving no bubbles and applying considerable pressure. The seepage I mentioned happens at any seams - not at the overlap but from the sides where there is inevitably a very slight lift between overlapping layers.

It took me a long time and I learned quite a bit about the technicalities of galvanized before I could locate material approximating what I want. That said, I do like the idea of very high grit 'scrubbing'. 2500 seems right. I don't think it would advantage adhesion, might actually diminish adhesion with its exceedingly slight introduction of variance into the surface. But I don't think it would be enough to matter and the trade off with a more matte look would be grand.

Thank you for the suggestion!

vitawells.net - Berkeley California

March 8, 2021

Junior Sales Representative - Resintech, Camden, NJ

Nadcap Chemical Processing Auditor - PRI, traveling

Process Engineer / Chemist - Denver Metal Finishing, Colorado

Q, A, or Comment on THIS thread -or- Start a NEW Thread