Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

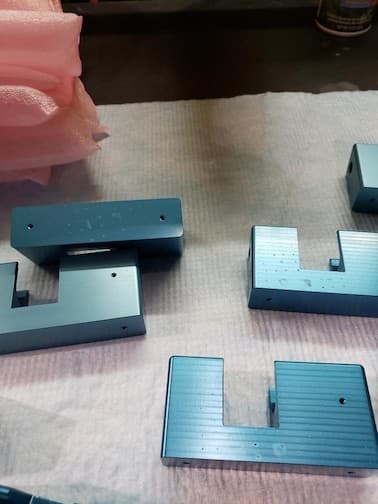

Numerous Type II Aluminum Anodizing Defects: Spots, No Color, Ink Stains

August 4, 2020

Q. I am having issues with my type 2 anodized pieces. They have spots, areas missing color, and even ink like looking spots. The vendor is only saying that is issues with the aluminum and offering no other solutions or insights. The parts are machined, cleaned, and dried before anodizing. I am not very knowledgable with the anodizing process so I was looking for some suggestions to solutions in helping with these re-occurring issues.

- St. Louis Missouri

A. Apologies that this didn't get posted in a timely fashion, Katie. Once in a while a posting gets lost for this reason or that.

I think the answer here is to send some parts to an alternate shop. Problems with the base metal do happen of course, but I don't believe the quality of the aluminum is the basic problem here: too many problems, too varied :-(

The white spots and ink stains in the last picture are too regularly spaced to be a random processing defect; looks to me like they were packaged while wet.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

February 2021

A. Some of the pictures show the possibility that, after good anodizing, some floating soil got in the pores and prevented the dye from getting in. You can detect this with a 10X magnify, look to see if the extrusion line goes right thru the bare spot, and looks properly anodized. Generally, spoken a little stronger than Ted above, seems poor workmanship. Another possibility, you did not identify the alloy, if it is in the 7000s and heat treated, then zinc molecules have come to the surface, fallen out, and left bare aluminum.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

February 24, 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread