Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

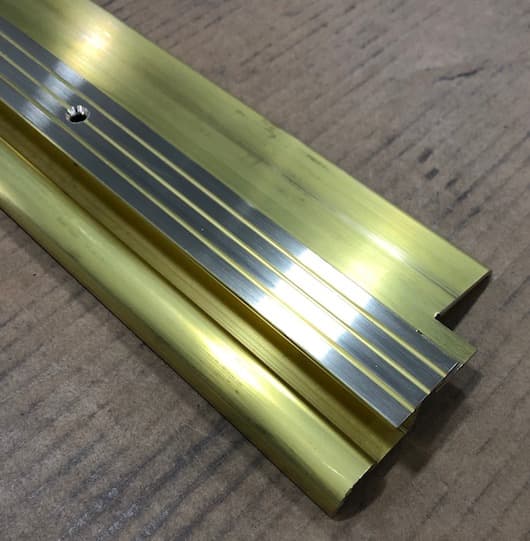

Brass threshold turned silver from Polishing

Quickstart:

A solid brass threshold which turned silver where polished appears to have been nickel plated, then topped with a brass colored finish, maybe electrophoretic lacquer or a PVD ZrN finish, presumably because the solid brass alloy was not considered aesthetic enough ... although possibly the contrast is nothing more than the fact that oxidized brass is darker than raw brass.

Q. Hi Brian,

Would you happen to know who manufactures your threshold (in picture)?

I have a similar one and I'm trying to find if an insulation piece that fits the slot.

Thanks in advance,

- Campbell, California

December 10, 2024

Tip: This forum was established to build camaraderie among enthusiasts through sharing tips, opinions, pics & personality.

The curator & some readers who publicly share their info will be less likely to engage with those who don't.

A. Hi Alwyn.

We'll see if Brian is responsive, but it looks like a 4", 4-1/4", or 4-1/2" 'interlocking threshold'. What is the heft of yours, does it appear to be the weight of brass rather than aluminum?

All I know is what I read in the googles, but it appears there are plastic or aluminum drip pan setups that can go under this, but I don't immediately see anything about insulation. The trough area is apparently for rainwater.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Hi Ted,

It is 4 1/4"wide. As far as the weight is concerned, I haven't pulled it apart as about a year ago, I had someone readjust the whole door with new hinges so it would close properly.

It's a 20+ year old piece for a residential door, so I'm guessing aluminum.

Your "interlocking threshold" was key in finding something similar online.

'Pemko 146 Series Residential Interlocking Threshold with Water Return, Widths of 4" and Heights of 1-1/4". '

Thanks for your help.

Best,

Alwyn.

- Campbell, California

December 11, 2024

⇩ Related postings, oldest first ⇩

Q. I have a forged brass (C377 - confirmed with a Niton Gun) door threshold that arrived in my shop with some surface marring. I polished the surface, by hand, with a red scotch-brite pad and the surface is now a bright silver color.

Is there a solution or polish I can purchase or make in order to restore the original, uniform yellow color?

Brian Mathey- Pleasant Prairie, Wisconsin USA

May 20, 2020

A. Hi Brian. As someone who has long since given up trying to judge what metal something is made of from its appearance, I'm certainly not about to look at a picture and then argue with a Niton Analyzer ... but have you analyzed against the possibility that while this threshold is made of C377, it might have a finish of bright nickel plating followed by brass plating, or s brass-tone lacquer?

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi Ted - thanks for the response!

It does look like this material has been plated or lacquered. It's very easy to remove the top layer, by hand, with scotch brite pad.

It looks as though I'll have to finish polishing this part to remove the marring and light scratches and then have it replated.

Any thoughts or recommendations on the above plan?

One other question. Why would a manufacturer make this threshold from C377 and then plate it with nickel and plate it again with brass? For increased toughness on the finished material? Door thresholds take quite a beating and I wonder if this type of fabrication is standard practice?

Thanks again!

Brian

- Pleasant Prairie, Wisconsin USA

A. Again, Brian, I'm not claiming that it IS nickel plated, only that it looks like it might be. I would think there should be a way of figuring it out, hopefully with your Niton XRF Analyzer. Until you know what it actually is, it's hard to figure out how to restore it to what it was.

I'd assume that most door thresholds at Loews and Home Depot are relatively cheap anodized extruded aluminum,; but solid brass is common for high traffic commercial thresholds :-)

My guess would be that it's difficult to get what the seller feels is a bright attractive finish from polishing the brass forging, so they nickel plate it and then add a color layer through some technology. That approach is widely taken with decorative plumbing fixtures (brass plating or brass colored finishes on solid brass faucet sets), so I suppose it could be done on thresholds.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Brian

The countersunk hole appears to show a silver metal as opposed to brass. If you did not polish it, I would suspect Ted is on the right track that it is anodized aluminum.

Are the ends of the threshold silver colored? It is easy for manufacturers to anodize long extrusions, then cut to length knowing the ends and holes will not show once in place.

- Green Mountain Falls, Colorado

May 23, 2020

Junior Sales Representative - Resintech, Camden, NJ

Nadcap Chemical Processing Auditor - PRI, traveling

Process Engineer / Chemist - Denver Metal Finishing, Colorado

Q, A, or Comment on THIS thread -or- Start a NEW Thread