Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

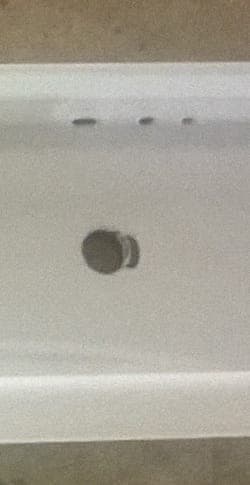

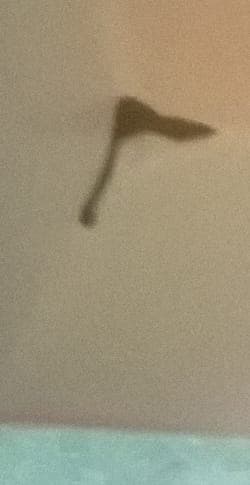

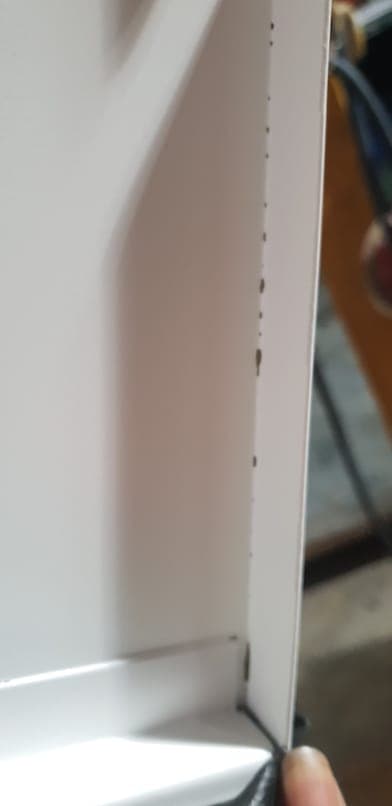

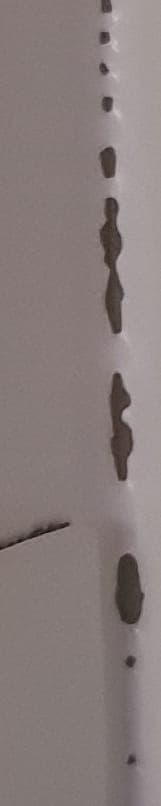

Bad powder coating on steel: Poor wet out surface defects

September 23, 2018

Q. Hello, we are a company working on steel. We are facing many lack of paint issues especially on the edges of the parts with some RAL composed of epoxy-polyester and polyester. At first I thought of Faraday cage effect, but after checking I realized that we use the tribo system, so this effect is not supposed to occur.

Our pre-treatment is a conversion one based on Zirconium nanocoating. Rinse waters have been checked and rust appearance has been mastered, but issues still appear after powder coating application.

Do you have an idea where these issues may come from?

I attach some pictures of defects:

Thank you

Nadia Bankole- Cairo, Egypt

September 24, 2018

A. This is almost certainly the result of spraying powder onto a wet substrate and then baking it out.

Hope this helps.

Regards,

Bill

Trainer - Salamander Bay, Australia

Q. Thank you for your reply, actually parts are well dried (oven) before coating application. This point has been already checked thoroughly.

Regards

- Cairo, Egypt

September 24, 2018

A. Hi Nadia. If they are not wet, then they are certainly dirty or inactive. This is not a powder quality or curing problem ... it's a substrate which either due to not being dry or not being clean or not being properly acid activated or having a deficient pretreatment is not accepting the powder properly.

I suggest sandblasting one sample before sending it through you pretreatment line. I am confident that it will come out fine and will remove your worries about Faraday cages, or other doubts about your powder and its application.

You might also try a sample straight from sandblasting to powder coating and, although it will probably won't prove satisfactory for the long run, I doubt that it will peel and pop at edges and corners like this.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

September 2018

Q. Hi Ted, in fact the pretreatment encompasses an acid cleaning, the conversion step. Then, there is the coating process. I made a wettability test just after the cleaning process and it was successful (the dropping water test).

We don't use sandblasting before the chemical process but rather a grinding step as a mechanical activation. Maybe I could explore a sandblasting approach.

What I don't get is that this problem only appears with some specific RAL. On some RAL we don't even face this trouble.

It's not a Faraday cage effect as we use a tribo system and not a corona one

Thank you for your help.

- Cairo, Egypt

September 25, 2018

September 2018

![]() Hi again. Well, if you know it's the specific powder then it's the specific powder and there's no more to be said. But it does strike me as very surprising based both on the look of the defects and the fact that the color of a powder coating really shouldn't radically affect your ability to apply it.

Hi again. Well, if you know it's the specific powder then it's the specific powder and there's no more to be said. But it does strike me as very surprising based both on the look of the defects and the fact that the color of a powder coating really shouldn't radically affect your ability to apply it.

I'm always happy to learn something knew, but I wish my confidence level in what I just learned was a bit higher :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread