Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Horizontal anodizing and white dot problem

Q. Hi,

I got involved in anodizing processes quite recently. I have done up to 6 Type-II aluminum anodizing so far, with good results. The cathode employed was aluminum plates arranged in a way so that the anodes where covered from all sides, except downside. The anode plate is put vertically, and the size of it is well enough to fit into the container's height dimension.

This time, I got a plate much larger than the previous ones. So large, I cannot put vertically, because of the container's insufficient height. I wonder if the anode plate can be put so it points downwards, like a horizontal arrangement. For this case, I would set an additional cathode plate in the base.

Could this arrangement be possible, so that the entire surface of my anode plate would be anodized?

Please let me know anything could happen as result of this arrangement (for example, differences into the anodized faces of the piece and whatnot). Thanks in advance!

- Dominican Republic

July 9, 2021

A. Hi Pedro. It is possible to anodize while the plate which is being anodized is lying horizontally in the tank. In fact, "continuous" reel-to-reel anodizing is done in this fashion. But it probably requires a cathode sheet above the anode as well as below it, and is probably not practical for a jobshop anodizer to try to do to handle oversize sheets this way because of a myriad of problems that may arise (no agitation on the top surface, oxygen bubbles accumulating on the bottom surface, poor rinseability, poor current distribution, etc.).

Although extrusion shapes can be racked horizontally, doing sheets horizontally is probably only practical if an anodizing line is carefully engineered for the specific purpose.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

July 2021

![]() Hi Ted,

Hi Ted,

First of all, thanks for the answer! I will try to anodize my plate so that the cathodes covers up the borders of the container, as well as below the anode plate.

As you state, putting a cathode plate above the anode may be impractical, but if necessary, I will give it a shot :)

Mechatronics Engineer - Dominican Republic

July 10, 2021

⇩ Related postings, oldest first ⇩

Q. Hi,

Currently we have problem that there are white dots in our hollow anodized profile. It should be no problem, but our customer is quite annoyed since they request to have clean inside and outside hollow profile.

We suspected on having impurities inside the profile.

So we have cleaned inside profile by doing water shoot per pieces before placing profile into the anodizing tank. however, the white dot is still there.

What is the actual root cause of this problem? for your information, we are using horizontal anodizing line.

PA Extrusion Sdn Bhd - IJOK, SELANGOR, MALAYSIA

July 31, 2018

? Can you share a pic (or more) about this problem?

alaattin tuna- sakarya, TURKEY

August 6, 2018

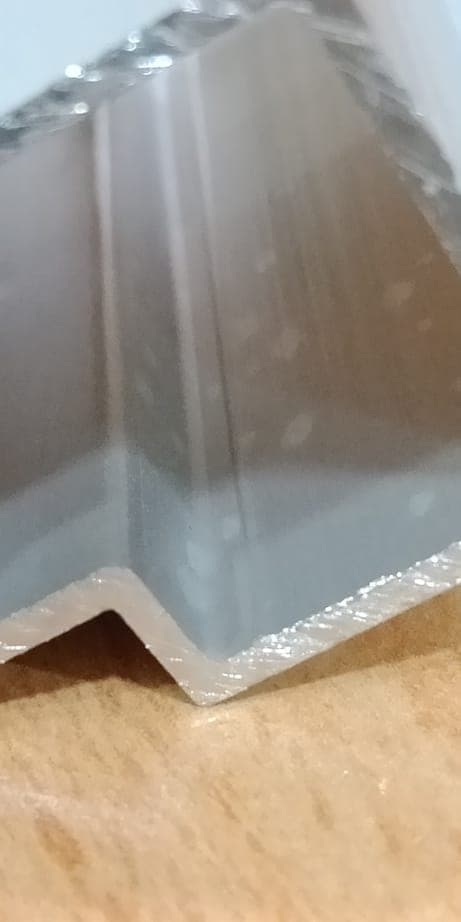

Q. Here is a picture of our situation. The dot will leave a mark if we swipe them. We try to reduce the length of the material, but this still can happen.

PA Extrusion Sdn Bhd - IJOK, SELANGOR, MALAYSIA

August 8, 2018

A. These are typical "Air bubble" marks.

Usually these white spots happen when the profiles are dipped into the tank horizontally with the help of a Rack -- because air gets trapped inside the hollow portion of the profiles, or in angular areas, or in grooves (if any) in flat profiles as well.

Therefore, to avoid such, rack the profiles at slight inclination so that there is a slope in all profiles to drain out the water as well as the air bubbles (if any trapped). And also in operation, while the rack with profiles is fully immersed in the tank, do an "up down" movement of the Rack within the liquid level. This will also help in removing trapped air.

Good luck.

- Asansol, West Bengal, India

August 18, 2018

![]() Thanks! I really appreciate this info. I will take that into account before setting the anode plate into the acid mix.

Thanks! I really appreciate this info. I will take that into account before setting the anode plate into the acid mix.

Mechatronics Engineer - Dominican Republic

July 10, 2021

Q, A, or Comment on THIS thread -or- Start a NEW Thread