Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

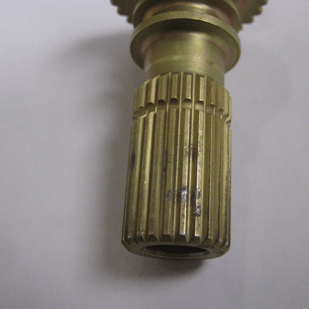

Arc burning on Cadmium Plating.

October 11, 2017

Q. We cadmium barrel plate. Normally runs very well. Of recent we are experiencing arc burns on components.

Have checked the electrics, all seems good. Perhaps we are missing something. Has anyone in the industry had experience of this.

Thank You. Nigel.

Process Technician - Northern Ireland

A. I have seen this happen.

Make sure your barrels are loaded properly. Especially make sure they are not under-loaded. This can lead to making and breaking contact and a small amount of the load can be subjected to excess current.

Typically when I have seen this happen it is in the electrocleaning which takes place before the cad plating operation, due to the higher current typically employed.

Therefore, if you are using an electrocleaner, in addition to not underloading the barrels, put the load in with the current off, then slowly ramp up to operating current over a couple minutes vs. subjecting the load to maximum current all at once.

- Sweden, Maine USA

November 2, 2017

A. Hi. These look like large and quite heavy items, but maybe they are actually small and the pictures are deceiving me. The reason for mentioning that is that I have seen small parts sort of float down instead of sliding down, making and breaking contact. Just reinforcing Peter's suggestion that an underloaded barrel (or one that is rotating too fast) can lift parts out of contact and result in this kind of arcing.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

November 2017

November 10, 2017

![]() Peter / Ted,

Peter / Ted,

Thanks for your feedback. Load size and not ramping up the current seem to be the issues causing the burning. Appreciate your help on this.

Regards

Nigel

Langford Lodge Engineering - Northern Ireland

Q, A, or Comment on THIS thread -or- Start a NEW Thread