-----

Should I use a Semi-bright or Bright Nickel Bath for my Brass Parts?

Q. I am a hobbyist and would like to nickel plate some brass parts for my own use that are smaller than fist-sized and are for decorative interior use. I am very familiar with buffing brass to a mirror finish and using the appropriate cleaning measures prior to clear-coating with lacquer (a lot of work!).

I would like to know if it would be simpler, yet more labor intensive, to plate these parts with a semi-bright nickel bath and then use the buffing process? Or, should I go ahead and use a bright nickel bath and forego the buffing? Will the buffed parts look as good or nearly as good as those using bright nickel? If proper technique is used, is one bath more easily kept in spec. than the other?

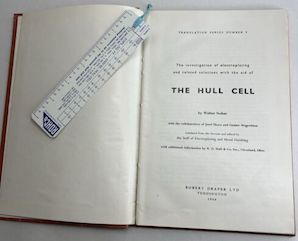

I will be using only the most basic carrier, wetting agent and brightener that are available to the home hobbyist since the 60's (not coumarin). The plating bath will be 10 gallons or less. The rectifier will provide 0-14 volts @ 0-185 amps. I have titanium baskets and heaters, s-rounds, polypropylene anode bags and filters, Teflon pumps, air and/or mechanical agitation, etc., etc., etc. I do not have a Hull Cell

⇦ huh?

yet.

I am very familiar with NPDES regulations and have most if not all of the publications in the recommended reading list.

Please let me know if I need to provide additional information for you to answer the questions in the second paragraph.

Regards,

Hobbyist - Prattville, Alabama, USA

August 3, 2016

A. Hi Kevin. You may know this, but as a preface so that we don't confuse other readers ...

The main use of semi-bright nickel is not as a final finish, but as an underlayer under bright nickel; and its function there is not decorative but for symbiotic corrosion resistance. Bright nickel is anodic to semi-bright nickel, so what hopefully happens is when corrosion starts in the outermost layer, the bright nickel offers cathodic protection to the semi-bright nickel so the corrosion spreads laterally and does not penetrate both layers and reach the brass.

With this in mind I think you should just use bright nickel. It is true that it is self-leveling so the underlying metal needs only polishing, not buffing. Still "show chrome" enthusiasts buff their copper layer anyway, and it does help, and if you were looking for the brightest possible nickel plating, you should too. But nickel tarnishes anyway, and the reason people choose it over nickel-chrome is the softer, yellower look. So you may not be looking for the highest possible reflectivity.

My opinion: rough polish the brass but don't buff it, then do bright nickel plating.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

August 2016

![]() Ted,

Ted,

Thank you for your response. I appreciate your help.

Regards,

Kevin

- Prattville, Alabama USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread