-----

Need a non-conductive finish for bendable stainless steel mesh

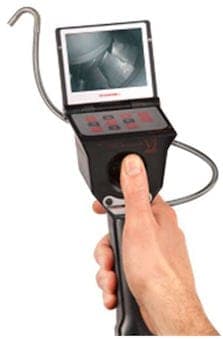

Q. We sell industrial endoscopes that feature a full articulating "bending section". The device is basically a medical endoscope used for looking inside industrial machines as opposed to a human body. The distal 3" of the insertion tube (round, 7 mm in diameter) is covered in a stainless steel mesh. We have a customer who requires that this distal section be non-conductive. Our current solution is the apply a "bending rubber" material to the entire section, thereby making it essentially identical to a medical endoscope. It is definitely non-conductive with the bending rubber applied, but this also increases the diameter and greatly reduces the achievable bending radius of the tip. So my question is, is there a coating out there (I'm hoping some type of spray coating) that will: 1. Make the bending section non-conductive; 2. Be permanent and not flake off the stainless steel mesh as it is deflected and moved in every direction, potentially thousands of times over its lifespan. This coating, if it exists, would have to permanently adhere to the tiny strands of the mesh in order to never come off.

Any advice would be greatly appreciated!

- Traverse City Michigan USA

March 12, 2016

A. Hi Sean.

I'd be skeptical of a coating both adhering to stainless steel and being reliably non-conductive. You might consider a teflon bellows style sleeve. These are comprised of a stack of very thin teflon discs with the appropriate size hole in them. The outside diameter of disc 1 & 2 are welded together, then the inside diameter of discs 2 & 3, then the outside diameter of 3 & 4, inside diameter of 5 & 6, etc.

At the ends, teflon tubes are welded onto them that can be stretched over the stainless ferrules of your endoscope for a friction fit or with some sort of clamp. It still might cause some issue with the size of the outer diameter, but you would not lose any flexibility at all, and it would be reliably insulating and easily replaced. Good luck.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

March 2016

A. Perhaps you could use a non-conductive sleeve at the articulating end to replace the stainless steel?

Ed Peters- Frederick, Maryland USA

April 11, 2016

Q, A, or Comment on THIS thread -or- Start a NEW Thread