Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Can a good zinc plated part get rusted?

December 18, 2015

Q. Dear Sirs,

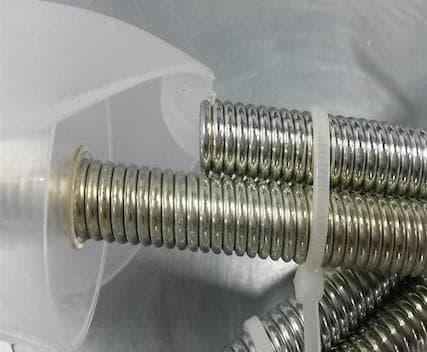

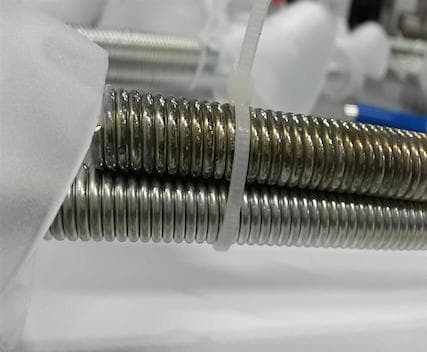

This is with respect to metal part in attached photos -- which has got rusty.

1. Final Customer requirement is 6 hours Salt Spray.

As precaution my Customer and we follow the below:

Zinc plating - Minimum 10 micron coating thickness and Spring should pass minimum 24 hours salt spray test.

And rating should be more than 5 (that's 4 times the requirement given by final customer).

Test Condition and test method for salt spray test: ISO 9227 Corrosion tests in artificial atmospheres--Salt spray tests

We recently got complaint from final customer per pictures attached:

We get this part done thru reputed plating vendor. Every lot has been salt spray tested by our plating supplier, then we are also doing every lot salt spray test and same is followed by our customer before assembling the parts at his end and then dispatching to final customer.

My customer stores all material in a heated room to avoid moisture.

Material sent June 2015 and complaint received on 15th Dec. 2015

What can be the reason for this part getting rusty --

1. Can it be moisture in Air at final customer?

2. Can one related reason for this metal part getting rusty after 4 -5 months (as no rust found before sea shipment)?

3. Parts have been assembled with plastics parts at our customer end manually?

4. Packing is in Carton boxes?

5. Can Glue of carton box - be culprit?

6. How to co relate with 6 hours of Salt Spray life required to rustiness after 4-5 months?

Please guide us.

Best Regards

- INDIA

Q, A, or Comment on THIS thread -or- Start a NEW Thread