Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Aluminum sheet shows stripes after chromate conversion coating

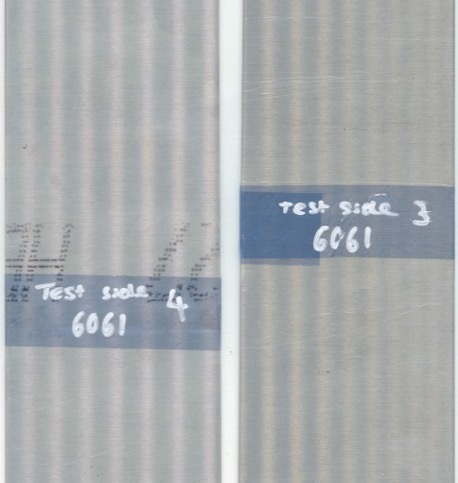

Q. Hello, I have been doing some salt spray testing, so to this end we have prepared several samples (various Al alloys). In the recent lot i have had 2024 and 6061 alloys treated with Surtec 650 (Immersion).

I realized that we developed some sort of stripes on our 6061 samples. They were not there immediately after treatment however they seem to have appeared before NSS testing. Post treatment they were stored (wrapped in paper) in normal (office conditions) for about 3 weeks. It is important to note that the stripes were only observed on 6061 and not on 2024 samples.

Just wondering what these stripes could be. The samples are cut from sheets of 6061.

- United Kingdom

September 23, 2024

Tip: This forum was established to build camaraderie among enthusiasts through sharing tips, opinions, pics & personality.

The curator & some readers who publicly share their info will be less likely to engage with those who don't.

⇩ Related postings, oldest first ⇩

Aluminum How-To

"Chromating - Anodizing - Hardcoating"

by Robert Probert

Also available in Spanish

You'll love this book. Finishing.com has sold almost a thousand copies without a single return request :-)

Treatment &

Finishing of

Aluminium and

Its Alloys"

by Wernick, Pinner

& Sheasby

(note: this book is two volumes)

on eBay or

AbeBooks

or Amazon

(affil links)

Q. My name is Lupe and I have a customer that I need help explaining the reason that the material that he is using is the cause for the marking on the material after the chemical conversion process. The rolled aluminum sheet is showing stripes at the ends of the sheet after chemical conversion coating process. The markings look like the wheels that the material was rolled with before cutting into sheets.

(Click thumbnails for higher rez photos)

Please advise if I'm correct. Thank you.

Lupe Benavidezplating shop employee - McAllen, Texas, U.S.A.

November 12, 2015

A. That is certainly what it looks like to me. It would be simple to take a quick measurement of the stripes and compare to the distance between the 2 wheels used in the manufacturing process, would it not? The question could then turn to whether there is anything you can do as a finisher to eliminate them. The only thing I can think of that may work would be to increase your etch time, assuming that is part of your pre-treatment process.

Marc Green

anodizer - Boise, Idaho

Q. Marc, I tried to explain that to my customer but they are not convinced that is the reason. Plus, they purchase the sheets from another supplier. I told them to check with their supplier but no answer has been communicated back to me. On the other note, we cannot increase etch time due to the longer etch appearance being whiter than they want.

Lupe Benavidez [returning]- McAllen, Texas, U.S.A.

In my experience, the 2 "lines" are just too perfect and uniform to be anything else but something caused during the manufacturing process. It could be the rollers, or it could be something else occurring prior to your seeing the parts. Sorry, I wont be able to help you convince your customer of that, though.

I would make sure you closely inspect the material next time it comes in to see if the defect can be seen prior to finishing, and maybe go as far as returning the material to your customer for re-finishing prior to your company even touching it, especially if they are going to reject your work after Chem film.

Marc Green

anodizer - Boise, Idaho

Q, A, or Comment on THIS thread -or- Start a NEW Thread