Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Ultrasonic Cleaning with Micro 90 ruined Electroless Nickel Plated Parts

May 21, 2013

Q. Our customer specified a new cleaning detergent (Micro 90) to use in our ultrasonic cleaner. We kept the solution at our standard temperature of 150 °F and ran the part for 15 minutes. The part is electroless nickel plated.

After running it in the ultrasonic cleaner it looked like this:

What do you think might be causing this staining? It can't be removed with IPA or Steel Ink Remover.

Dave Sheff- Amherst, New York, USA

January 4, 2019

Q. I'm actually looking for any similar issues; I heard Micro 90 should not be used on steel parts -- plastic only to prevent discoloration. I am hearing conflicting statements though.

What is your percentage of Micro 90 to water? I hear it is supposed to be 2% or lower to prevent discoloration.

What is yours?

Precision Swiss Products - Milpitas, California, USA

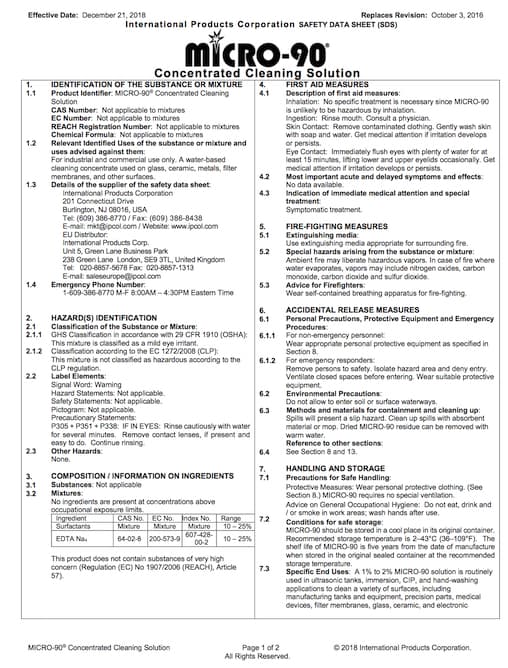

A. Hi Michael. I don't know if Dave will reply since his posting was from 5-1/2 years ago. More enthusiasm towards participating in the discussion might arise if we can make it a bit more generic rather than being about one specific trade secret formulation ... it seems to be EDTA and surfactants, and the SDS does say it etches nickel.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q, A, or Comment on THIS thread -or- Start a NEW Thread