Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Corrosion resistance of 316L Electropolished Stainless with waterjet cutting marks

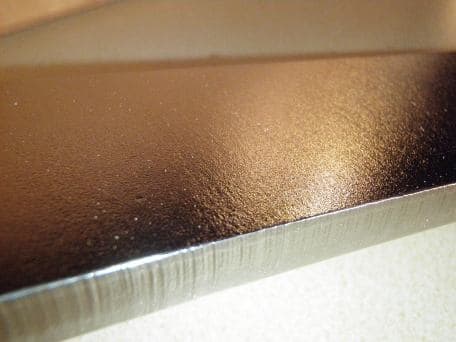

Q. I recently had custom 316L stainless steel parts fabricated for the 36' sailboat I'm building. Crevice corrosion is a major concern with these parts. The parts were waterjet cut from 3/8" sheet with some holes drilled in them and some bending. One part has a weld. When asked about finishing I specified electropolishing as everything I'd read led me to believe this was an excellent way to enhance corrosion resistance. I expected the parts to have a mirror smooth finish. When the parts arrived, the flat surfaces of the plate had distinct orange peal and the edges still had waterjet cutting marks. Everything was bright and shiny from the electropolishing, it just wasn't mirror smooth. Aesthetically the finish is fine, but I worry about corrosion in the marine environment. Here are my questions.

1) Are these parts more susceptible to corrosion than parts that have been mechanically polished and buffed to a mirror smooth finish prior to electropolishing?

2) If so, can these parts still be mechanically polished or finished in some way to obtain a mirror smooth finish and then electropolished again?

3) If so, what type of finishing should be specified prior to electropolishing to obtain increased corrosion resistance?

Thanks in advance.

Building a 36' Sailboat - Potterville, Michigan, USA

October 2, 2012

A. Hi Jon. I may be misreading the photo, but it looks like no smoothing, deburring, or polishing of the cut edge was done between plasma cutting and electropolishing. I think that is wrong; you don't want clumps of metal overhanging the cut edge like that. I think had the cut edge received just a little bit of mechanical correction before electropolishing everything would be fine. But you won't get a mirror finish from electropolishing alone.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

October 5, 2012

Q, A, or Comment on THIS thread -or- Start a NEW Thread