Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

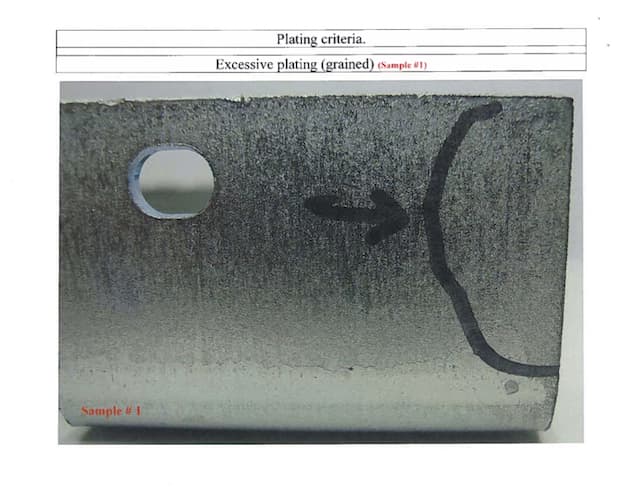

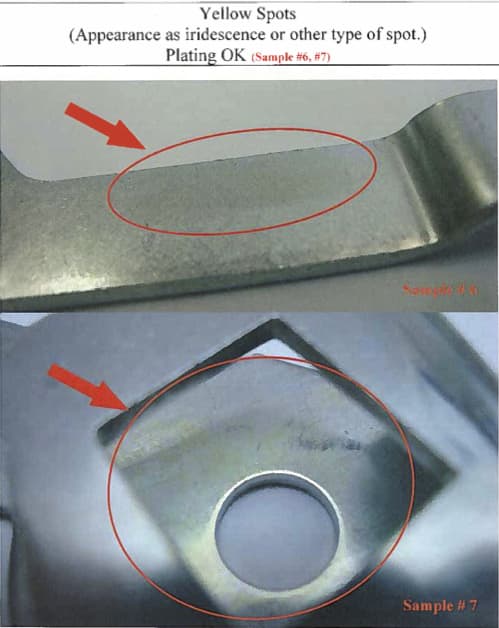

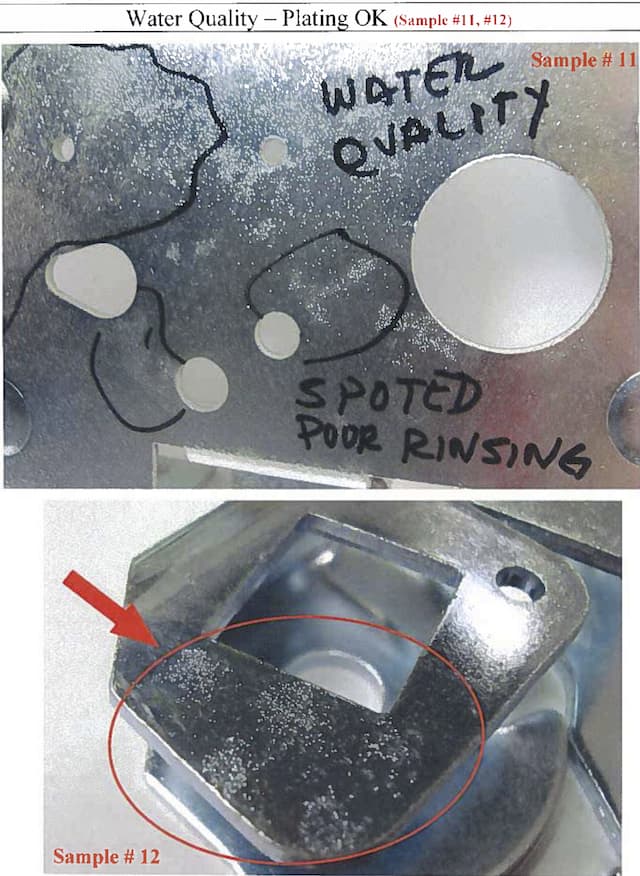

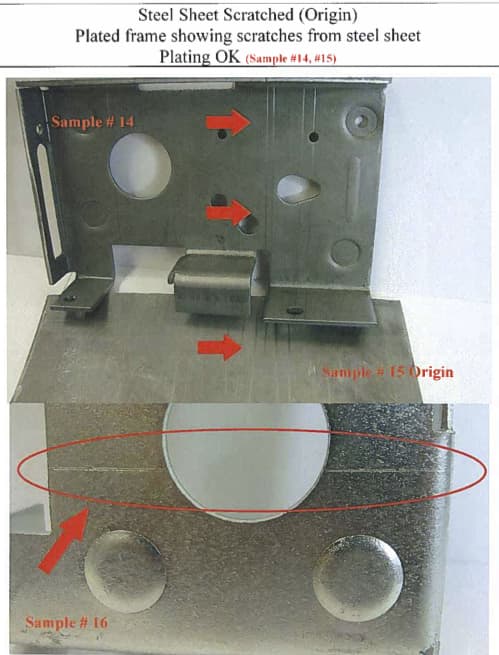

Visual Blemishes in trivalent chromate passivation on zinc plating

June 15, 2012

Q. Our plant has been receiving steel parts plated with a trivalent zinc chrome coating that have a variety of blemishes. We are attempting to determine which types of blemishes in this type of coating are ones that affect the coatings performance and which ones are acceptable/passable for use.

I was hoping to get some advice on this, or at least some advice on where I could find more information on the subject.

Thanks,

- Cleveland, Tennessee, USA

June 20, 2012

Q. Some more details:

We have already made acceptance decisions on several of the blemishes shown above. What remains to be answered is which of the remaining blemishes could from a performance standpoint be considered passable. These remainders include:

Samples 2 & 3: What in the plating process could cause these marks, and would the take away from the effectiveness of the plating.

Samples 4 & 5: What in the plating process could cause these marks, and would the take away from the effectiveness of the plating

Samples 6 - 10: All of these are samples that have issues with color. I know yellow is a characteristic color of hexavalent, if the parts are yellow or have yellow spots could this mean they do in fact have hexavalent passivation? There are parts that seem to be iridescent, what could this mean? Finally there is plating that seems opaque; it is greyish and has no reflective quality.

Samples 11 - 13: Are spots caused by poor quality rinsing water an issue, or could they be passed?

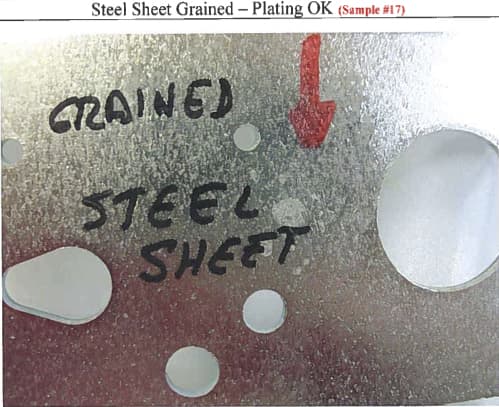

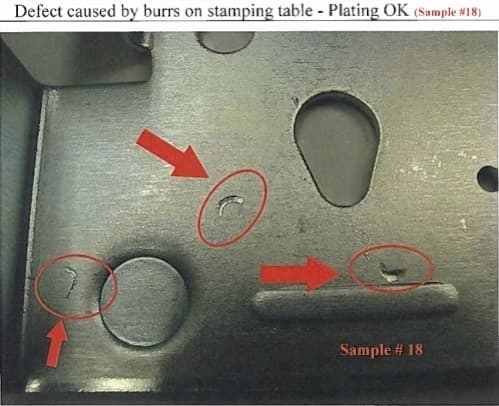

Samples 14 - 18: These were all flaws in the manufacturing process, and we do not believe they should change the plating's effectiveness

- Cleveland, Tennessee, USA

A. Hello Quinn Killogh,

Sample 2 shows the shadow of one part on the other and is the outcome of parts touching whilst racking;

Sample 3 is from a badly maintained plating bath (blisters on the edge) and the water mark you see is either from the base metal ooze out or improperly dried and rinsed in hard water in the end.

Sample 4 and 5 are variations of Sample 3.So are samples 6 and 7 - a combination of bad sheet metal followed by bad plating.

Sample 8 looks like its come out of a chloride plating process, sample 9 and 10 are out of Alkaline plating but with different passivation processes, one a trivalent blue and the other a yellower one.

There is no need to assume that they are Hexavalent; the yellow tone is normal for a good trivalent and works better than the blue when testing for white rust resistance.

Looks like you are trying to put a lot of parts together from different suppliers; the sheet metal is quite terrible and a platers nightmare actually. The plating is largely inconsistent as well.

Khozem Vahaanwala

Saify Ind

Bengaluru, Karnataka, India

June 24, 2012

WE WANT TO GET RID 100% THE WATER MARKS WHICH APPEAR BELOW THE BLUE ZINC PASSIVATION. PLEASE SUGGEST.

KUSHAL GOYALENGINEERING WORKS - Bangalore, Karnataka, India

March 18, 2013

Q, A, or Comment on THIS thread -or- Start a NEW Thread