Curated with aloha by

Ted Mooney, P.E. RET

The authoritative public forum

for Metal Finishing 1989-2025

-----

Need disposal info about an old plating product

May 9, 2012

Q. Hello,

Let me start off by explaining a bit about how I have come to have this stuff first. My grandfather started a vacuum tube rebuilding company way back in 1940, and sometime between then and now they started plating (mostly with silver) the tubes that were rebuilt. This forum has helped me a ton in learning how to deal with this process over my 10 years of running the place, but now the business has been sold and I'm cleaning out.

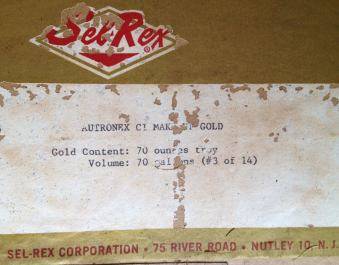

The silver plating solution I already know what I can do to reclaim the silver, however, when cleaning out my back building I discovered eleven 5-gallon boxes of some kind of gold plating solution and not sure of the amount of gold within. Before I send it off to be reclaimed I would like to make sure I know how much gold is actually in each box. It was made by Sel-Rex and the label has:

Autronex CI MAK... Gold

Gold content: 70 oz Troy

Volume: 70 Gallons

I assume this means there is 1 oz per gallon, anything someone could tell me would be much appreciated.

Joel

- Covington, Louisiana, USA

A. I worked for Sel-Rex in the late 60s, early 70s. One of my jobs was to supervise the manufacture of these solutions. The Autronex CI bath contained a small amount of cobalt (hardener) and 1 tr.oz. of gold per gallon. It was in a potassium citrate/citric acid matrix and had a pH of about 4-4.5. The gold is added in the form of potassium gold cyanide. The gold deposit purity was 99.9%. The solution was made up in a plastic tank and then was transferred to cubitainers (boxes).

Assuming the original solution is in those cubitainers, there should be 1 tr.oz. of gold per gallon or, 5 oz per 5 gallon cubitainer. The solution should be a light pink color from the cobalt. If there is any precipitate settled out after all of these years, it could contain gold, probably as the yellow gold cyanide compound.

- Nevada, Missouri, USA

First of three simultaneous responses -- May 12, 2012

A. In thinking about my last post, it's much more likely he used the solution and then, when he shut down, he stored the solution in the original containers. So, depending on how much plating he did and how often he replenished the gold, the gold content in the solution could be all over the map. However, maybe the solution had evaporated from 70 to 55 gallons before he put it into the boxes. That could raise the gold concentration.

There could be a lot of money involved. Before I dealt with a refiner, I would certainly want to know the total value. This can be easily done by transferring all the solution to a clean plastic vessel that will hold it all (a graduated one would be best), stirring the solution well, dipping out a sample, and taking it to a lab for gold analysis. When pouring the solution out of the cubitainers, be careful to not pour off any solids that have settled on the bottom. Collect all the solids together in a separate container (bucket). They may or may not contain gold. Somewhere I have a file on how to re-dissolve those solids so they can be sampled and assayed. I'll look for it. In any case, the liquid and the solids (if there are any) should be treated separately.

- Nevada, Missouri, USA

Second of three simultaneous responses -- May 12, 2012

A. Hello Joel,

Because there is a possibility that you have a fair amount of gold there and considering the current price of gold, an independent lab analysis of the solution would be your first step. Hopefully there is a lab in your area that has an AA or can do gravimetric analysis for gold concentration and purity. In doing this, you know what you have before you deal with a refiner. The refiner will also know you are educated and would be less likely to line their pockets. Like any business, there are some out there that are not very reputable. If you can get a hold of a DOT approved 55 gallon drum, carefully pour the 5 gallon containers into the one drum and mix well. Take (3) 50 ml samples from the drum. send one to the lab and save 2. If time allows, have a Refining Rep come in and sample the drum and seal it. The drum stays with you until you agree with the refiner's results. I would choose a company that sells precious metals for electroplating,and have them transport the sample. Another reason for choosing a reputable refiner is because you are responsible for that solution until it is disposed in the proper manner (cradle to grave). They will help you with the transportation requirements of the drum. I know the whole process sounds time consuming, but you may as well get a fair return. Good Luck!

Engineering - Mesa, Arizona, USA

Third of three simultaneous responses -- May 12, 2012

A. Mark Baker has given you all the right answers. Grandpa may have left you a very nice legacy.

Jeffrey Holmes, CEF

Spartanburg, South Carolina

May 18, 2012

How to make plating solution from gold powder?

Q. I just found a 1 oz. Bottle of Autronex gold powder. That is all the label has on it.

Autronex 1 Troy oz. Gold.

Since I plate my gold, I would like to know how to mix this one ounce of powder into gold plating solution.

Can anyone out there help?

Rick

opals/jewelry - Newport, Washington

April 5, 2014

April 9, 2014

A. Hello Richard,

There are a few common formulations. I prefer the buffered citrate type formulation. For rack plating:

Gold - 4-5 grams per liter

Potassium citrate - 40 grams per liter

citric acid (adjust pH to 4.5)

DI water

95 °F

If a hard gold deposit is preferred, I would purchase a proprietary brightener i.e., Cobalt, Nickel, or Silver. As you may know, the brightener also provides an improved grain structure, and less porosity in the deposit. This formulation is sufficient for jewelry, and decorative items. You will deposit 20 microinches with no problem. Plating time would depend on solution, rack agitation, bath temperature and placement of the inert anodes. Good Luck!

Process Engineer - Malone, New York USA

Q, A, or Comment on THIS thread -or- Start a NEW Thread